techXXX

Nissan VR38DETT vs Alfa Romeo 690T (Quadrifoglio): Iconic Designs Compared

Today, I compare the design of the Nissan VR38DETT found in the R35 GT-R and the Alfa Romeo 690T found in Quadrifoglio models along six aspects: engine block, bank angle & crankshaft, oil pump, displacement & stroke ratio, fuelling, and valve timing.

Published by Dr Jiulin Teng on 25 May 2024

Keywords: engine

Today, I compare the design of the Nissan VR38DETT found in the R35 GT-R and the Alfa Romeo 690T found in Quadrifoglio models along six aspects. Again, we omit the accessories.

Engine Block

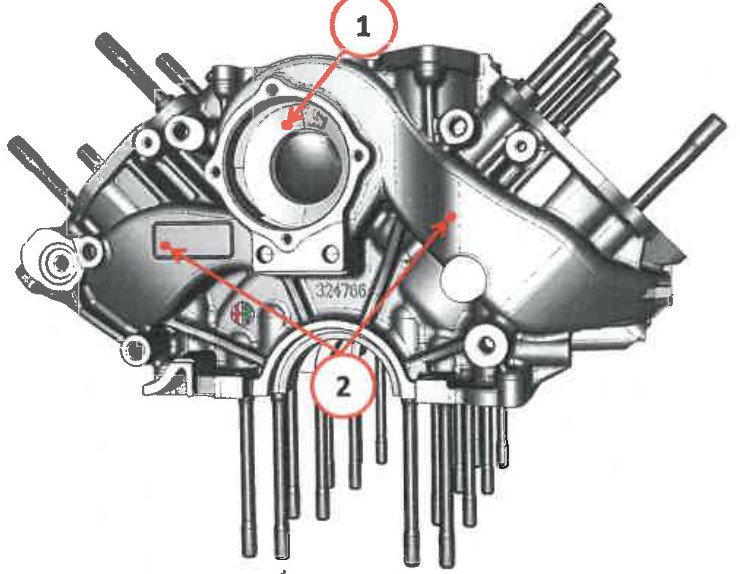

Both engines use aluminium block with a bedplate that sandwiches the crankshaft with four bolts on each main bearing. Alfa Romeo refers to the piece as “under-block”; it is more complex than the one Nissan uses, as this under-block also acts as the windage tray with three reed valves.

The VR38DETT uses plasma-sprayed low-carbon steel coating, much like contemporary German engines. The 690T, on the other hand, has pressed-in steel liners that are only found in high-performance engines; even Porsche does not use it. The 690T also uses studs for fastening the bedplate and the engine heads. Studs are superior to bolts in many ways and are again found only in high-performance engines and the likes of old Rolls-Royce engines.

While the VR’s block is exceptionally strong, the Alfa’s block is luxurious for its class.

Bank angle & Crankshaft

The Nissan has a 60-degree bank angle, while the Alfa is a 90-degree V6. With a 60-degree bank angle, the VR38 has six individual rod journals measured at 56mm in diameter each. This makes it possible to achieve even firing, but the reciprocating forces of the engine are not balanced.

With a 90-degree bank angle, the 690T has only three rod journals measured at 47mm in diameter each. The crankshaft is simpler, and the reciprocating forces of the engine are balanced. However, this makes for an odd-firing engine with 90- and 150-degree firing intervals. Because the overlap of the power strokes is small in the 150-degree interval, the movement of the crankshaft is not balanced.

Neither is as ideal as an inline-6, but neither uses balance shaft. This is because balance shafts would add to the inertia of the rotating assembly.

Also worth noting is that Alfa Romeo advertises nitride surface treatment on the crankshaft, which is another premium feature.

Oil pump

The VR38DETT uses an internal gear oil pump, while the 690T uses a variable displacement oil pump. The former is simpler and more robust, while the latter is more efficient.

Displacement & Stroke ratio

While both are oversquare engines, the VR38 is appreciably larger in displacement, with 95.5mm bore and 88.4mm stroke and a 9:1 compression ratio. The 690T has 86mm bore, 82mm stroke, and 9.3:1 compression ratio. The larger bore on the VR significantly increases headline air flow volume; however, the Alfa probably has higher intake and exhaust air flow velocity.

Fuelling

The Nissan is port injection-only. The Alfa Romeo originally had only direct injection with two high pressure fuel pumps. Later, port injection has been added.

The only downsides to the 690T’s setup are complexity and reduced headline air flow volume.

Valve timing

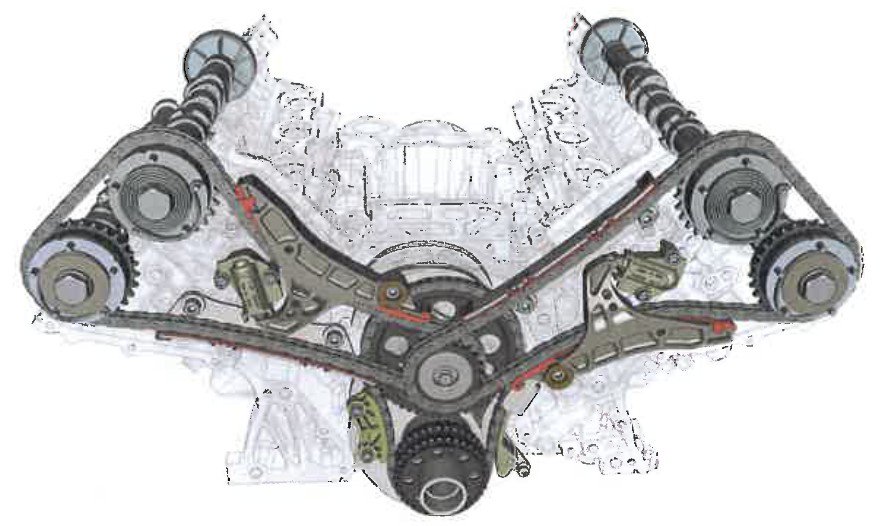

The VR has variable valve timing only for the intake side. Its timing chain setup is very simple. One downside is that the water pump is also driven by this chain, which makes for more involved replacement.

The 690T has VVT on both the intake and the exhaust sides. It can reach 70 degrees of valve overlap. Its rear-mounted timing chain setup is more complex. There is also cylinder deactivation for the right cylinders.

In conclusion, the Alfa Romeo 690T is significantly more advanced. But for the cast pistons, its short block is almost luxurious. However, some aspects of its complexity cast doubt on its long-term durability.

For high power builds and long-term collections, the Nissan VR38DETT is a better choice. It is likewise robust but considerably simpler. Most importantly, its 3.8L displacement is much higher than the Alfa’s 2.9L. In the end, there is no replacement for displacement.