techXXX

Dynamic Fuel Management in LT Engines Is the Most Advanced Cylinder Deactivation Technology Today

Today, I briefly cover how GM’s Dynamic Fuel Management (DFM) system works. It should then be obvious why it is superior to conventional cylinder deactivation technologies.

Today, I briefly cover how GM’s Dynamic Fuel Management (DFM) system works. It should then be obvious why it is superior to conventional cylinder deactivation technologies.

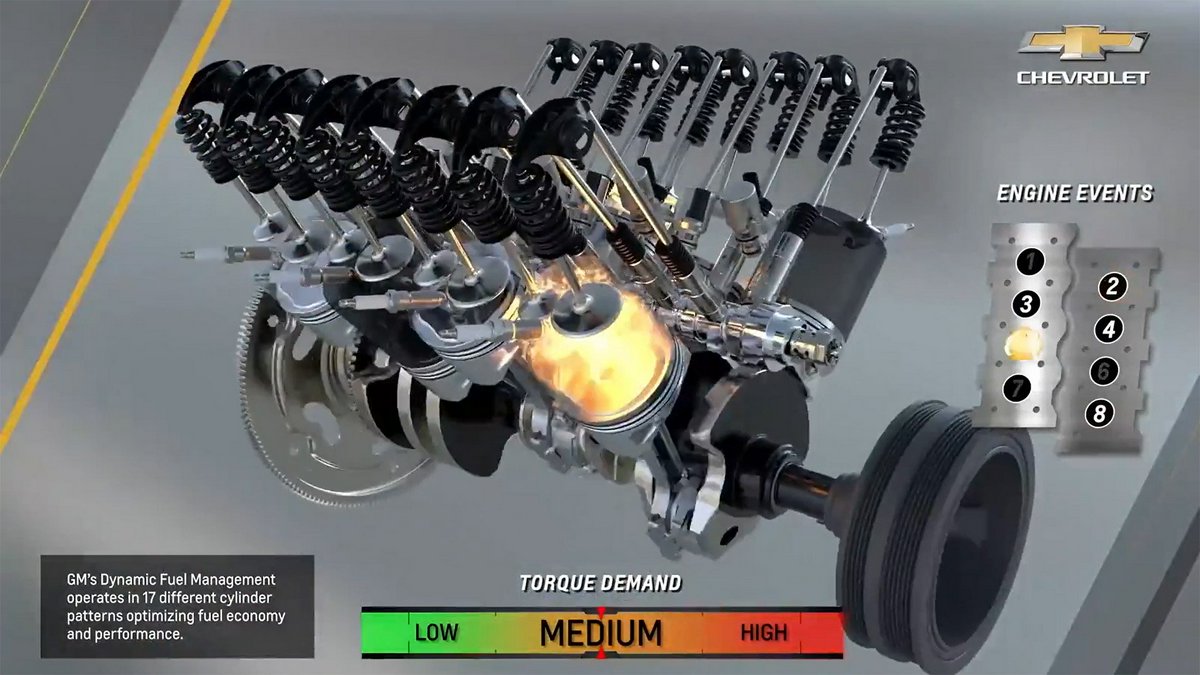

Traditionally, a fixed sets of cylinders are deactivated under part-load operating conditions. However, they all have drivability and NVH problems. DFM adopts the Dynamic Skip Fire strategy that not only continuously varies the number of firing cylinders but also continuously rotates the cylinders being deactivated. This strategy greatly reduces drivability and NVH issues associated with cylinder deactivation and, as a consequence, also simplifies the entire engine, as it does not necessitate complex accessories to mitigate these issues, for example in the engine mount and exhaust system.

GM’s 5th-gen small block engines are best suited to adopt Dynamic Skip Fire strategy, because it only has a single camshaft and was already designed to work with Active Fuel Management (AFM) system. Hence, the main hardware differences between DFM and AFM are in the doubling of the oil control valves from four to eight.

As it is in the AFM, each solenoid valve controls both the intake and the exhaust lifters of a cylinder. The ECM starts deactivating a cylinder during the intake stroke. The intake valve opens but is subsequently locked in the deactivated position as it closes. The exhaust valve is closed at this point and is deactivated immediately.

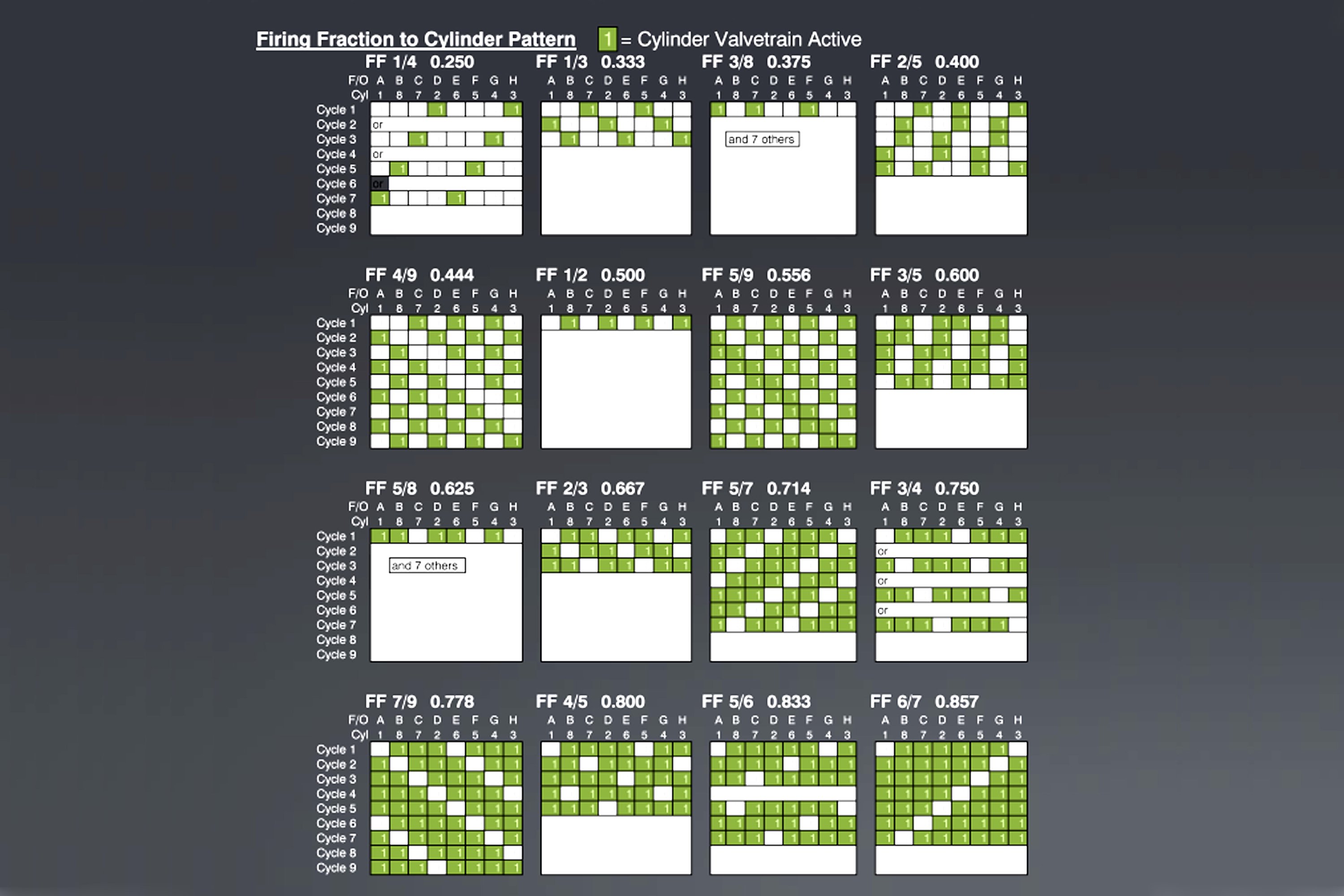

The magic of DFM happens with the Engine Control Module (ECM). This system can vary the percentage of working cylinders from 1/4 to 6/7 in 16 different patterns, as is shown in the illustration. Most notably, the ECM rotates the cylinders being deactivated through cycles. The primary goal of this rotation is to eliminate the drivability and NVH-related problems of conventional cylinder deactivation technologies; in other words, to improve engine balance.

Still, there are two additional advantages: One, with Dynamic Skip Fire strategy, the engine has much more flexibility in adapting to part-load conditions; it can start deactivating cylinders much earlier, resulting in considerable improvement in efficiency. Two, since no cylinder is being deactivated for sustained period of time, excessive wear associated with cylinder deactivation is also avoided.

All these advantages do not come without cost. Many owners report premature lifter failures, which GM has blamed on bad batches of lifters. While that may be the case, very frequent switching of the lifters between the on and off states naturally wear them out faster than it is with the old AFM system. This trade-off in lifter wear is likely the reason why GM has only put the system in two truck engines so far, the 5.3L L84 and the 6.2L L87.