techXXX

BMW N63 vs N63TU vs N63TU2 vs N63TU3: Evolutions of the Bavarian Hot-V8

Today, I delve into the mechanical evolutions of the BMW N63 hot-V8 biturbo engine by highlighting the most consequential changes in 6 areas from the original 2008 N63 to its three subsequent updates in 2012, 2016, and 2018.

Today, I delve into the mechanical evolutions of the BMW N63 hot-V8 biturbo engine. Unlike some manufacturers who are tight-lipped about changes made to their engines over the production run, BMW is kind enough to provide exhaustive details on each technical update. I only highlight the most consequential changes in 6 areas from the original 2008 N63 to its three subsequent updates in 2012, 2016, and 2018.

Short Block

The original N63 has an Alusil crankcase with double main bearing bolting and additional side wall bolting. The main bearings measure 65mm in diameter, a reduction from 70mm in the N62.

With the N63TU, BMW modified the rotating assembly completely with a forged crankshaft, forged connecting rod, and new cast piston with optimized crown shape. These changes accompanied a decent bump in power output.

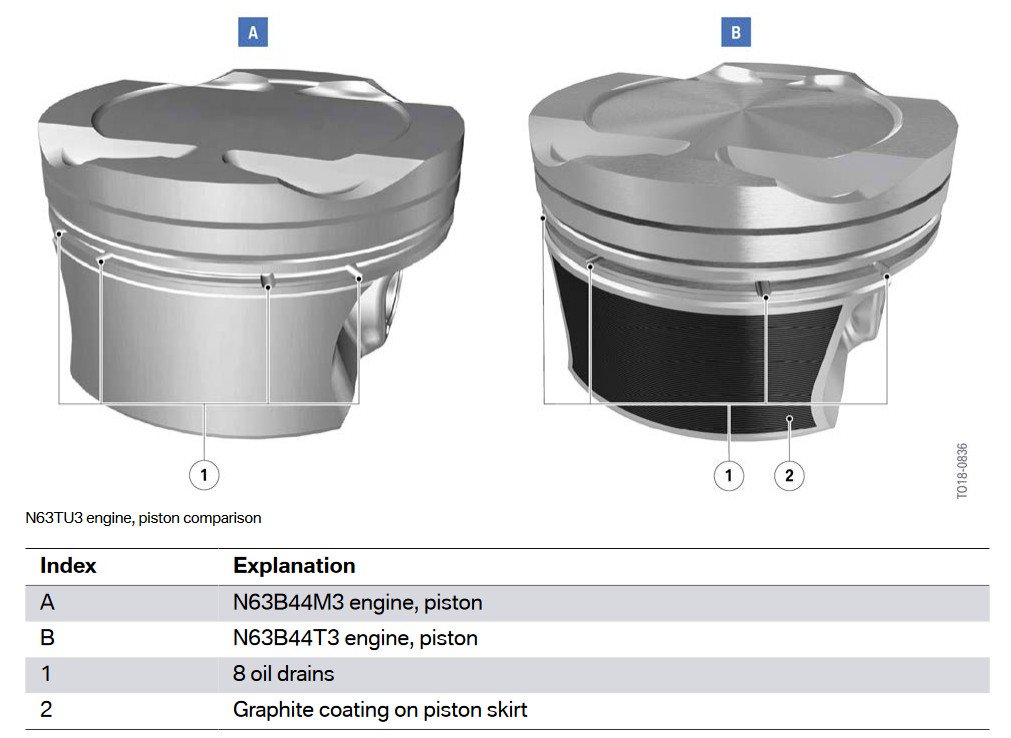

With the N63TU2, BMW further added IROX anti-friction coating on the top bearing shells for the conrod. This is the same material that I have mentioned in previous articles, including on the N74TU. As it is with the N74TU, the N63TU2 also received modified pistons with double the oil drains and an additional oil groove. These updates should cut oil consumption. BMW also increased the compression ratio.

With the N63B44T3, which is the high-output version of the N63TU3, BMW replaced the Alusil process with electric arc wire spraying to manufacture the crankcase. Naturally, this version uses a different coating on the piston skirts to work with the new bore surface. The N63TU3 also uses IROX coating on the main bearing shells. The N63B44T3 now uses the conrod of the S63B44T4, while the low-output N63B44M3 uses the conrod of the S63B44T2.

Cylinder Head & Valvetrain

On the original N63, the exhaust valve lift curve on cylinders 2, 4, 7, and 8 were different: they open later and have a shorter duration and a lower lift. BMW said that this improves engine smoothness.

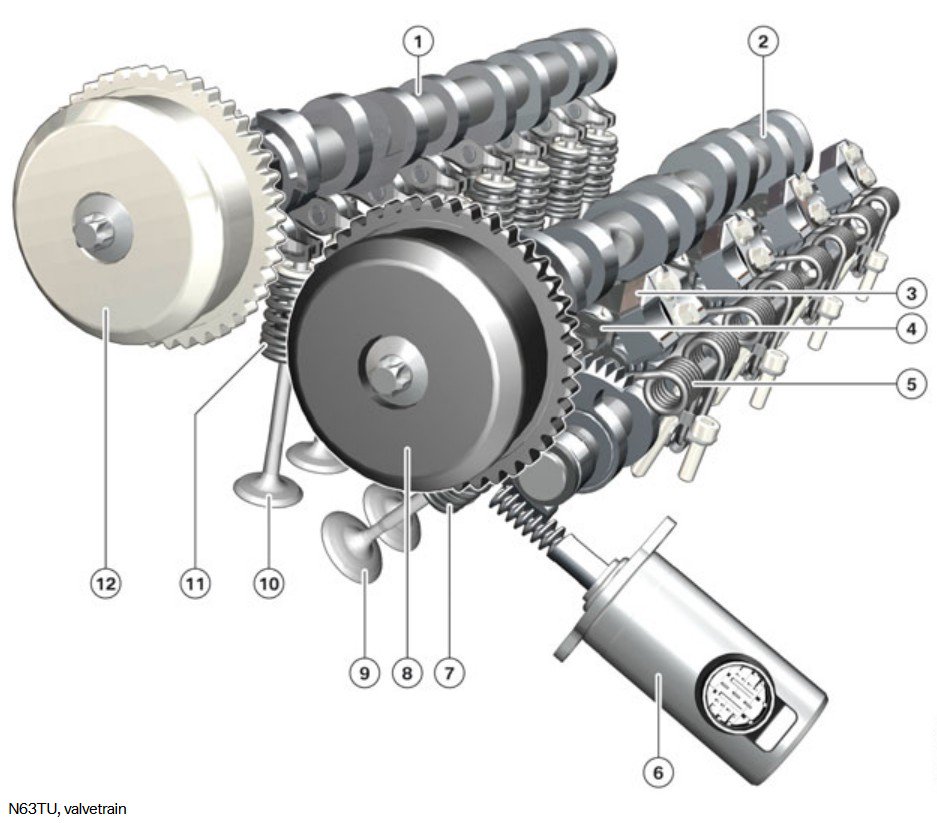

With the N63TU, BMW completely redesigned the cylinder head to work with 3rd-gen Valvetronic, which was introduced with the N55. VANOS and timing setup are updated to work with this system. BMW also updated the head cover to work with the modified crankcase ventilation system, with the goal of reducing oil consumption.

With the N63TU2, BMW again modified the crankcase ventilation system and the head cover. The cylinder head has also been modified with partial integration of the intake runners. The head gasket has been improved, too. BMW also updated the material of the valve guides as well as the valve stems, obviously all in an attempt to curb oil consumption.

With the N63TU3, BMW tweaked the header cover, cylinder head, and head gasket once again.

Oil Supply

The original N63 used a pendulum slide cell positive displacement pump driven by a chain off the rear of the engine.

With the N63TU, BMW made the pump smaller, ostensibly to improve efficiency.

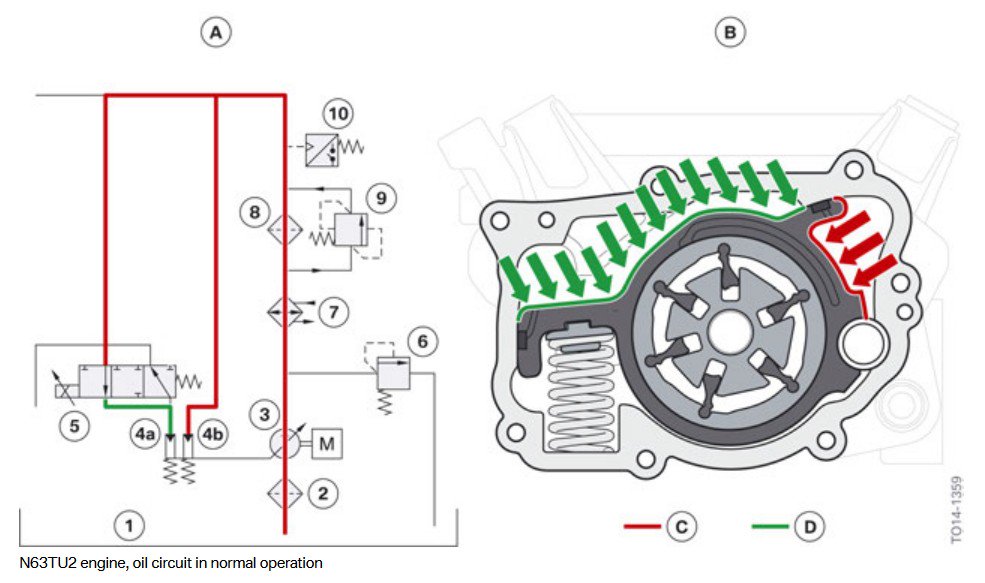

With the N63TU2, BMW added characteristic map control and an oil pressure sensor. It works in the same way as found in the N74TU, which I have detailed previously. It seeks to save fuel by reducing oil pressure.

Cooling

When it comes to cooling, BMW included the two engine control units in the low-temperature coolant circuit with the N63TU, as it is on the N74TU.

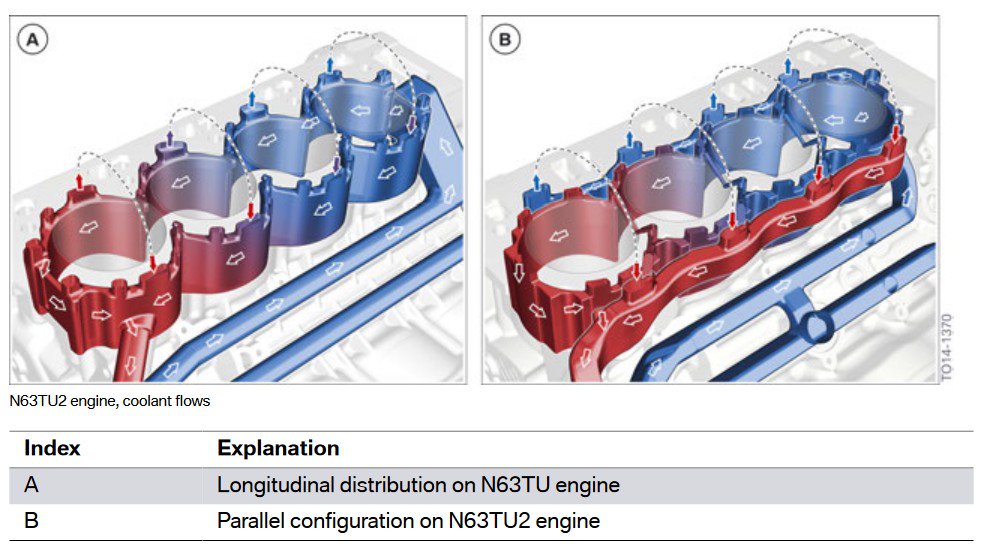

With the N63TU2, BMW heavily modified the coolant circuit and added a characteristic map-dependent water pump. While previously the crankcase was continually cooled in what BMW calls “longitudinal distribution”, the N63TU2 employs the “Split Cooling Combined” (SCC) concept wherein during the warm-up phase 90% of the coolant is bypassed in what BMW calls “parallel configuration”. This speeds up the warm up process and saves fuel.

Exhaust & Turbocharger

The original N63 was the first modern hot-V8 biturbo engine. Most of its troubles come directly or indirectly from this architecture.

With the N63TU, BMW updated the turbochargers and removed the blow-off valves. BMW said that blow-off valves are not needed with Valvetronic.

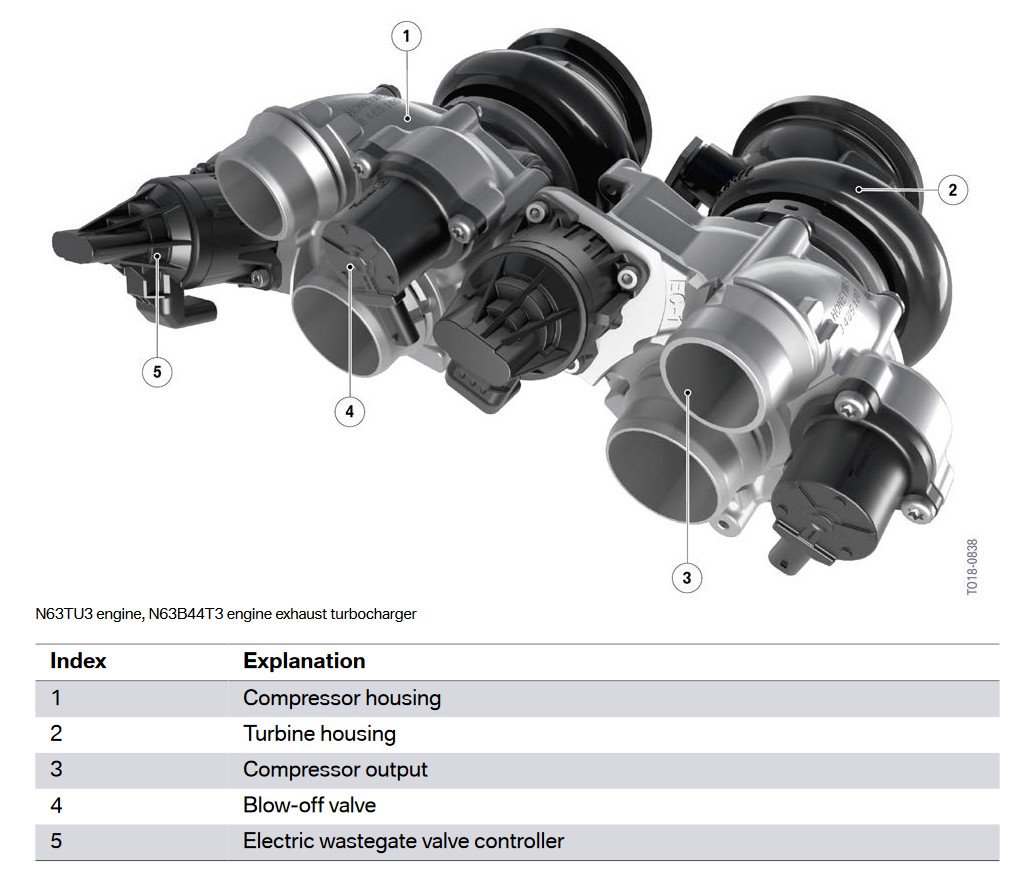

With the N63TU2, BMW modified the exhaust manifolds and upgraded the turbochargers to twin-scroll units. The pneumatic wastegate valves were replaced by electric wastegates. At the same time, the exhaust flaps were also updated from pneumatic to electric actuators. Like it is with the N74TU, this greatly simplified the vacuum system. Originally, the pneumatic wastegate and exhaust flap actuators got vacuum from the vacuum reservoir hidden inside the hot-V, a design that further undermined the engine’s reliability. From the N63TU2, only the brake booster is driven by the vacuum pump directly.

With the N63TU3, BMW added Overboost function to the low-output N63B44M3. More interestingly, the high-output N63B44T3 received electric blow-off valves. It seems that these are not as useless as BMW formerly said anyway. BMW also added a bypass line between the charge air coolers, which improves torque, throttle response, and acoustics.

Fueling

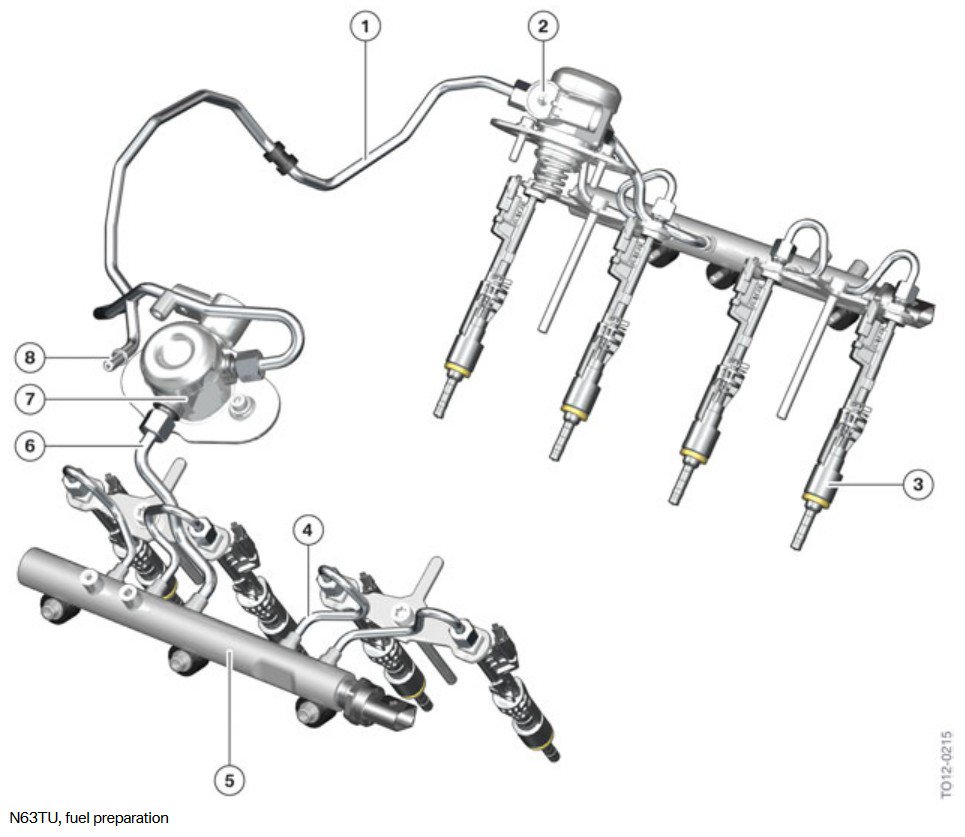

The original N63 used BMW’s High-Precision Injection (HPI) system. It used piezo-electric injectors just like on the N54 and N74.

With the N63TU, BMW moved to high-pressure injection (HDE) with solenoid valve injectors, as found in the N55 and N74TU.

With the N63TU3, BMW increased the fuel system pressure from 200 bar to 350 bar. This improves fuel atomization.

Conclusion

What originally made the N63 the worst modern V8 was BMW’s courageous choice to put the turbochargers in the valley of the engine. This created all sorts of heat-related issues that ranged from heat stress on the rotating assembly, excessive oil consumption, overheating, pre-ignition, and turbo failures. Piezo-electric fuel injectors did not help, either. Overtime, BMW attempted to cure these issues, and by all accounts the latest N63TU3 is one of the better hot-V engines in production. However, there is no fix for a bad architecture, and even the latest N63TU3 is not as reliable or as durable as non-hot-V designs.