techXXX

ZF 8HP 8-Speed Automatic Transmission Deep Dive

The ZF 8HP represents both a major evolution in the philosophy of the 6HP and a considerable revolution in gear train design. Today, let us analyze its advantages and trade-offs and delve into how its gear train works.

Published by Dr Jiulin Teng on 30 Dec 2025 · Updated on 06 Jan 2026

Keywords: transmissionzf

Debuted in 2008, the ZF 8HP represents both a major evolution in the philosophy of the 6HP and a considerable revolution in gear train design. It has become the industry benchmark. Today, let us analyze its advantages and trade-offs and delve into how its gear train works.

Advantages

1. Elegant Gear Train Design. Using four simple planetary gearsets and five friction elements, the ZF 8HP gets 8 forward gears. While this may sound ordinary after the Aisin 8-speed, it minimizes torque reversals. The torque paths that it forms, especially in Gears 4 and 5, are mind-blowing. This has profound influence on subsequent designs.

2. Positive Clutch-to-Clutch Shifts. Thanks to its elegant gear train design, the ZF 8HP can execute positive clutch-to-clutch shifts, whereby only one friction element is engaged while another is released in all gear changes and without torque reversals.

3. Three-Path Torque Converter. While Aisin and Toyota have long-used three-path torque converters, ZF introduced this design to the 8HP, thereby greatly improving TCC (torque converter lock-up clutch) control and lifespan. The three-path design has an additional circuit in the torque converter dedicated to TCC control. Subsequent transmissions all adopt this design.

4. Aggressive TCC Lock-Up Strategy. While the ZF 6HP allowed more slips in the TCC and could never fully lock up, the ZF 8HP has a much more aggressive TCC lock-up strategy. It has a much lower TCC slip target across the board, and can even execute full lock-up, where the slip is under 10 rpm. This combined with Points 1 and 2 has given the ZF 8HP a more direct, more engaging feel that many love.

5. Compact. The ZF 8HP is very small for an 8-speed automatic transmission.

6. Scalable and Modular. The 8HP is exceptionally scalable and modular. Torque capacity can go from 300 Nm to 1000 Nm. It was also designed from the start to accommodate start-stop and hybridization.

Trade-Offs

1. Difficult to Tune. While elegant, this gear train and clutch-to-clutch shift strategy demand careful tuning for each engine–vehicle combination. The transmission will misbehave unless it is well-tuned. Not all car manufacturers have done it in all their cars across all engine options.

2. Chain-Driven Oil Pump. To reduce the axil length and to accommodate start-stop and hybridization, the oil pump is moved away from its usual position. This necessitates a more complex and potentially less reliable setup.

3. Bushings, Improved. ZF has greatly improved the bushings in the 8HP over the 6HP. Combined with more positive TCC lock-up, these bushings last considerably longer. However, they are not bearings.

4. Drums. While elegant, this gear train design necessitates the use of large drums to connect the elements. These drums, when rotating, can sap power. They are also relatively fragile.

5. Parasitic Gear Rotation. In most gears, some gearset(s) rotate without transmitting power.

Gear Train

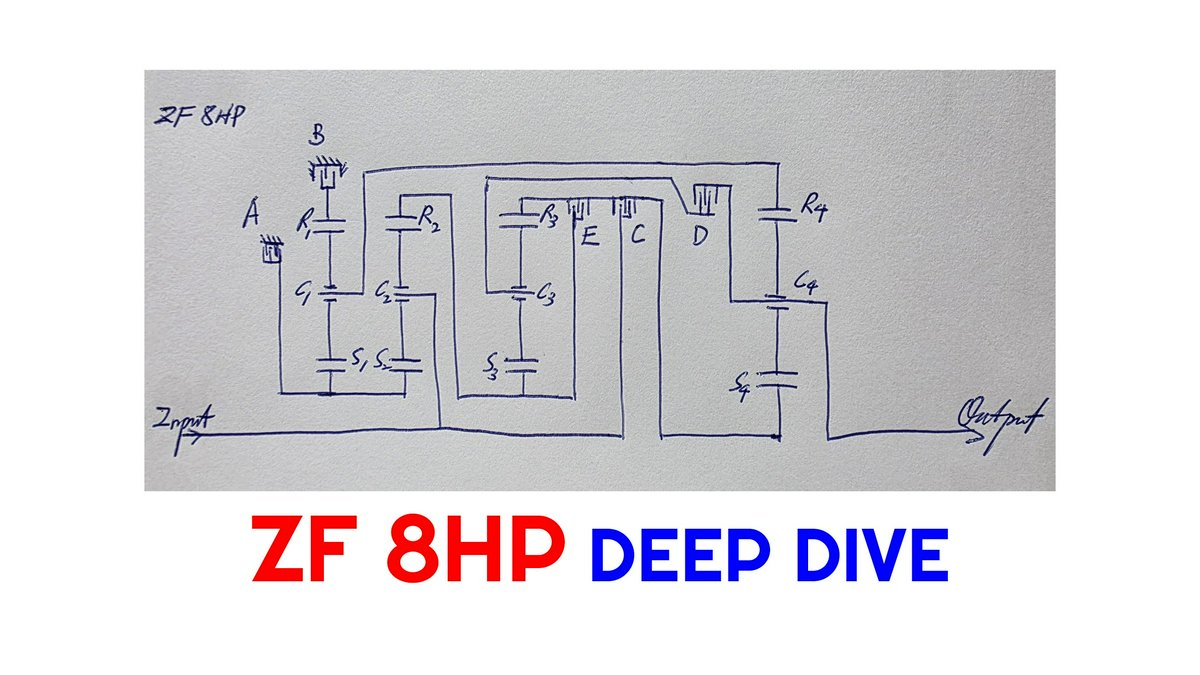

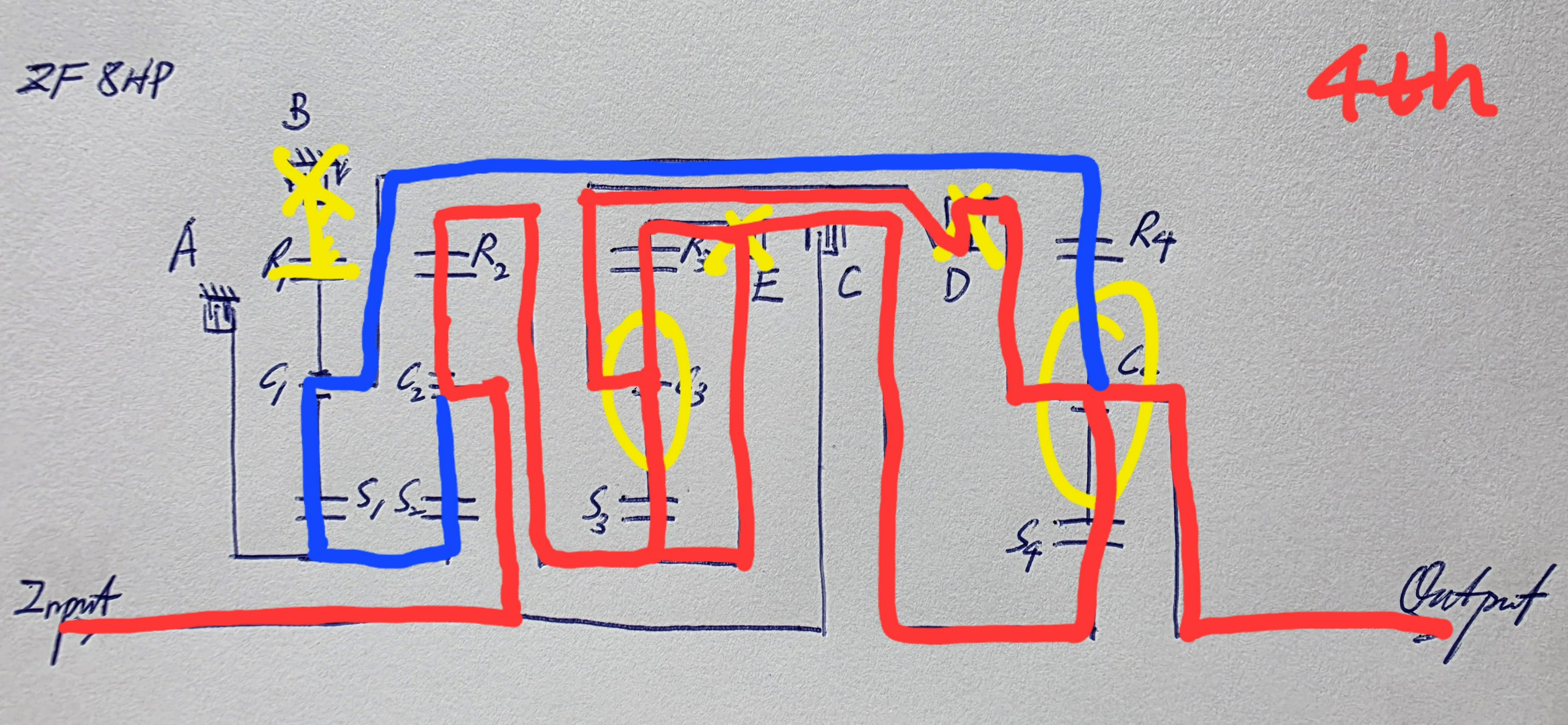

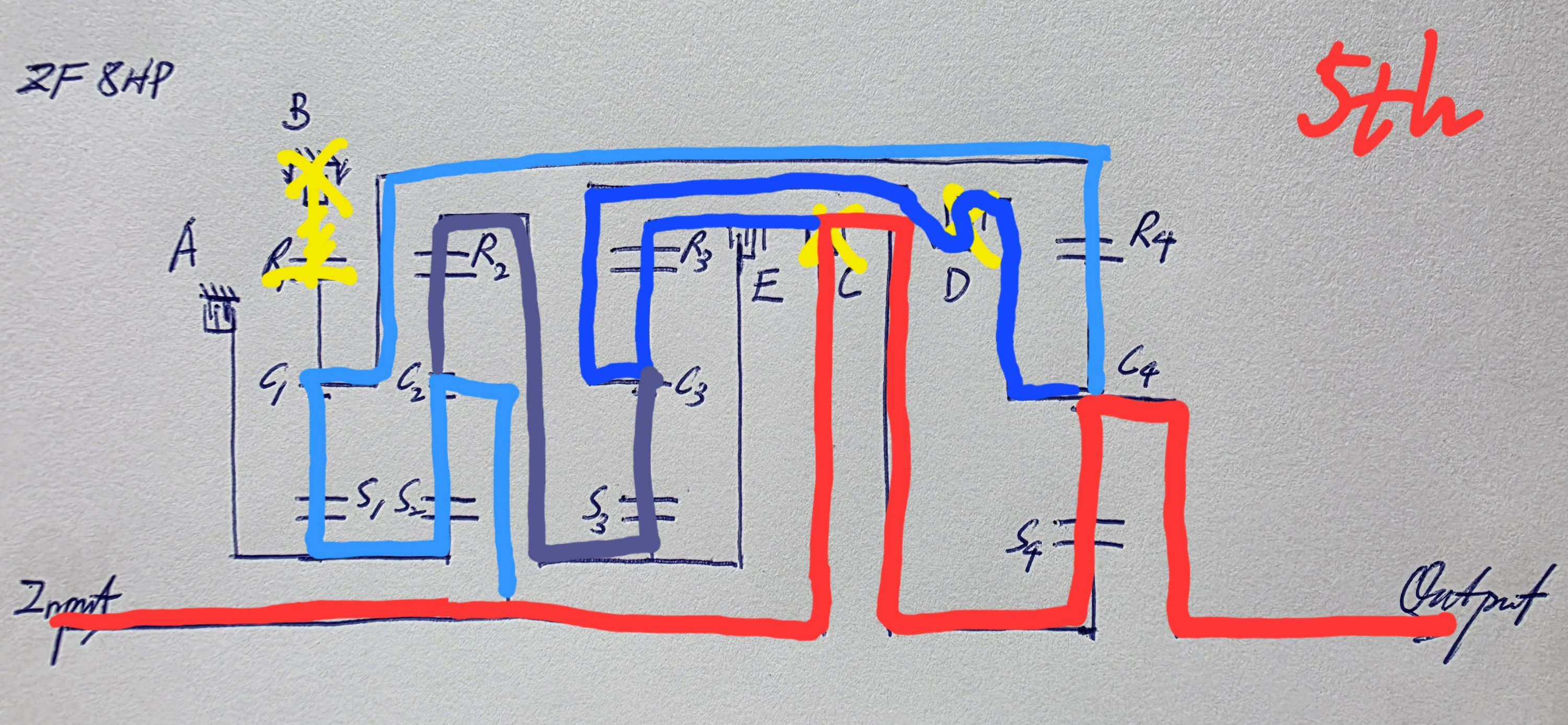

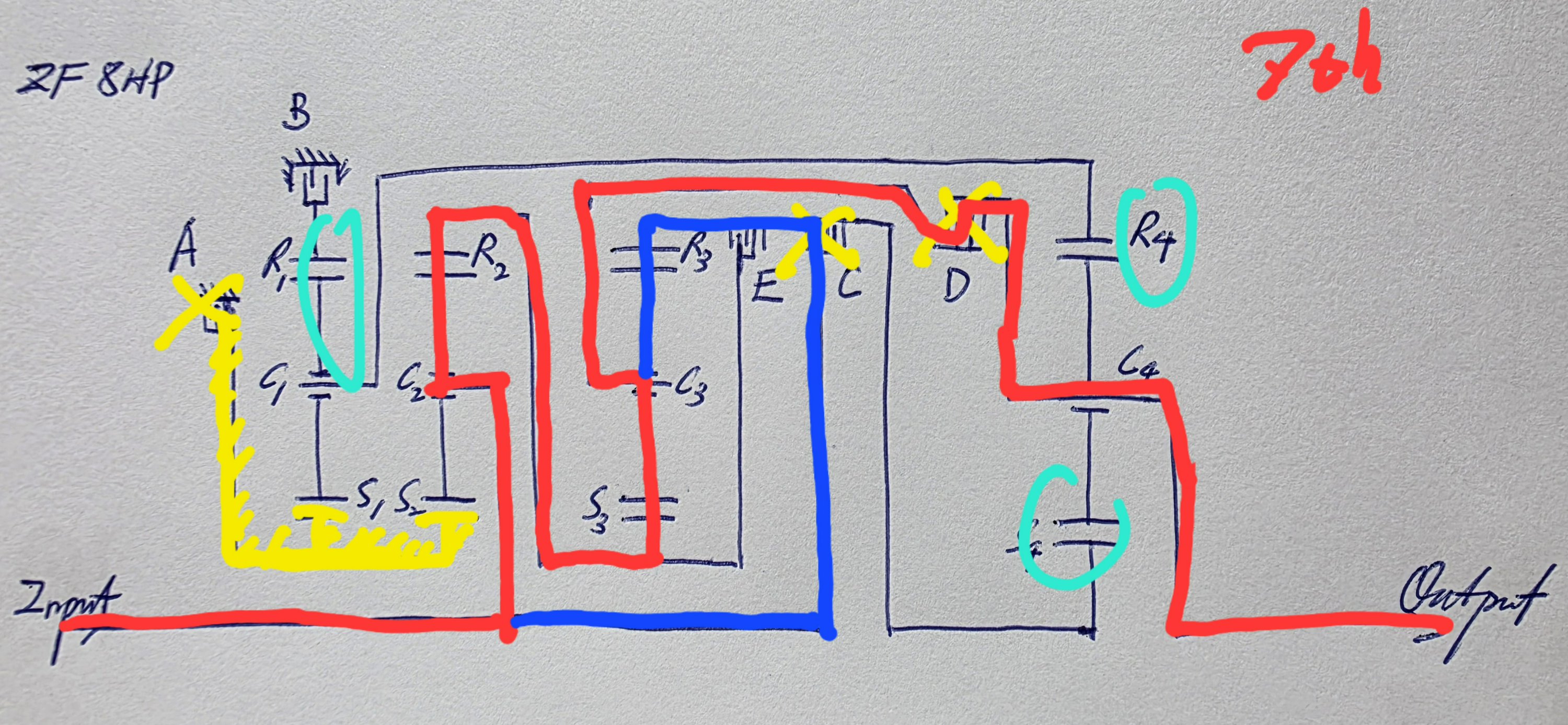

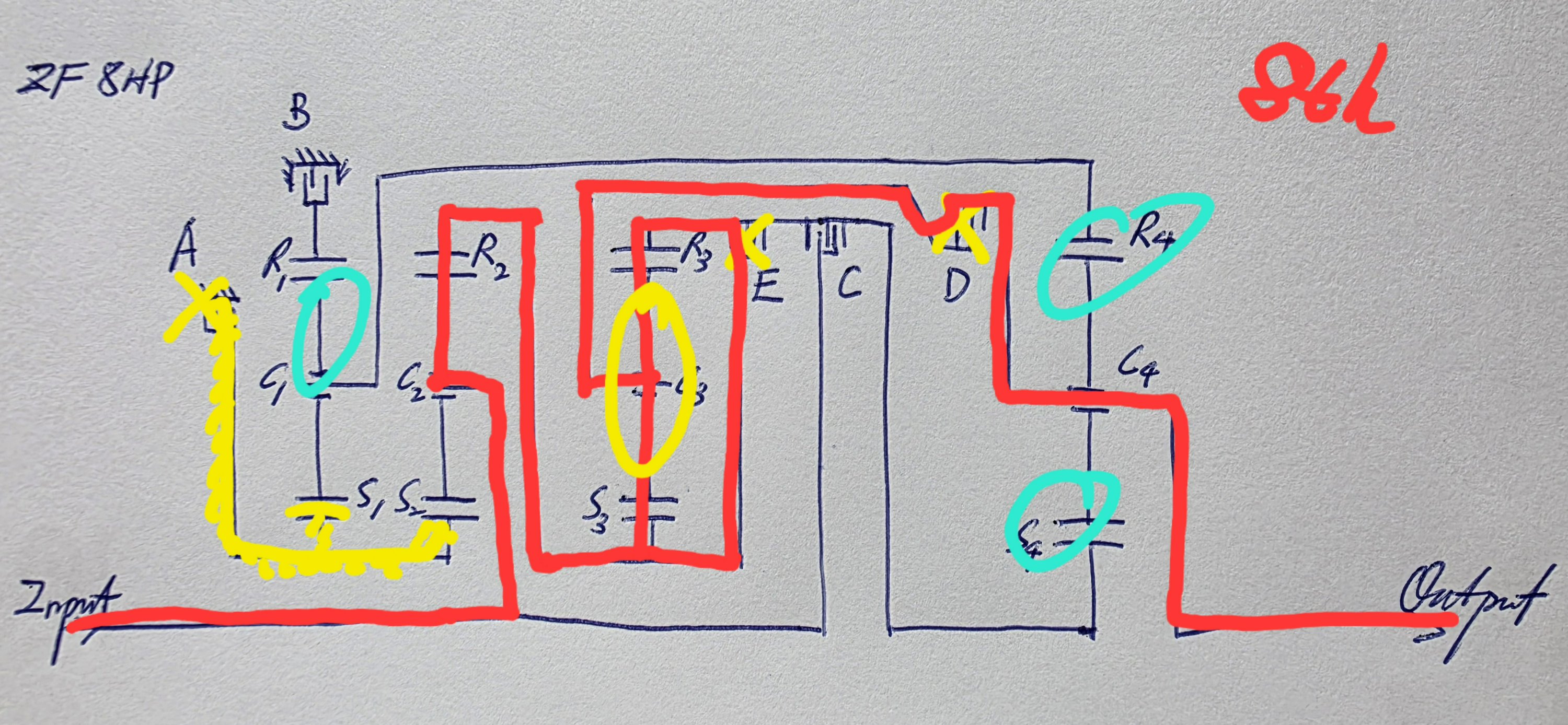

Now let us look at the gear train schematic of the ZF 8HP, which was drawn by me. Friction elements A and B are the brakes, while C, D, and E are the clutches. From the front to rear, there are four planetary gearsets, each with its sun gear, carrier, and ring gear marked out.

Torque Paths

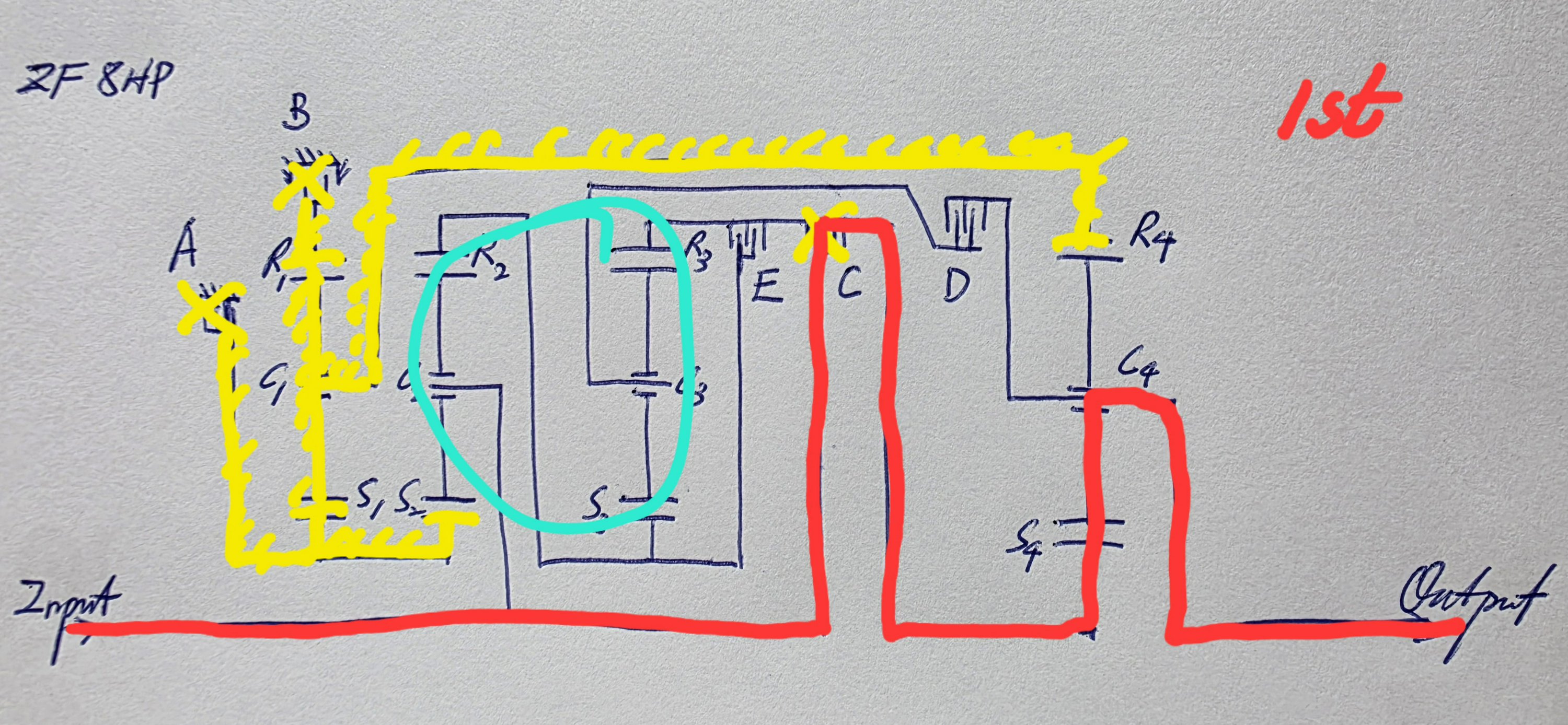

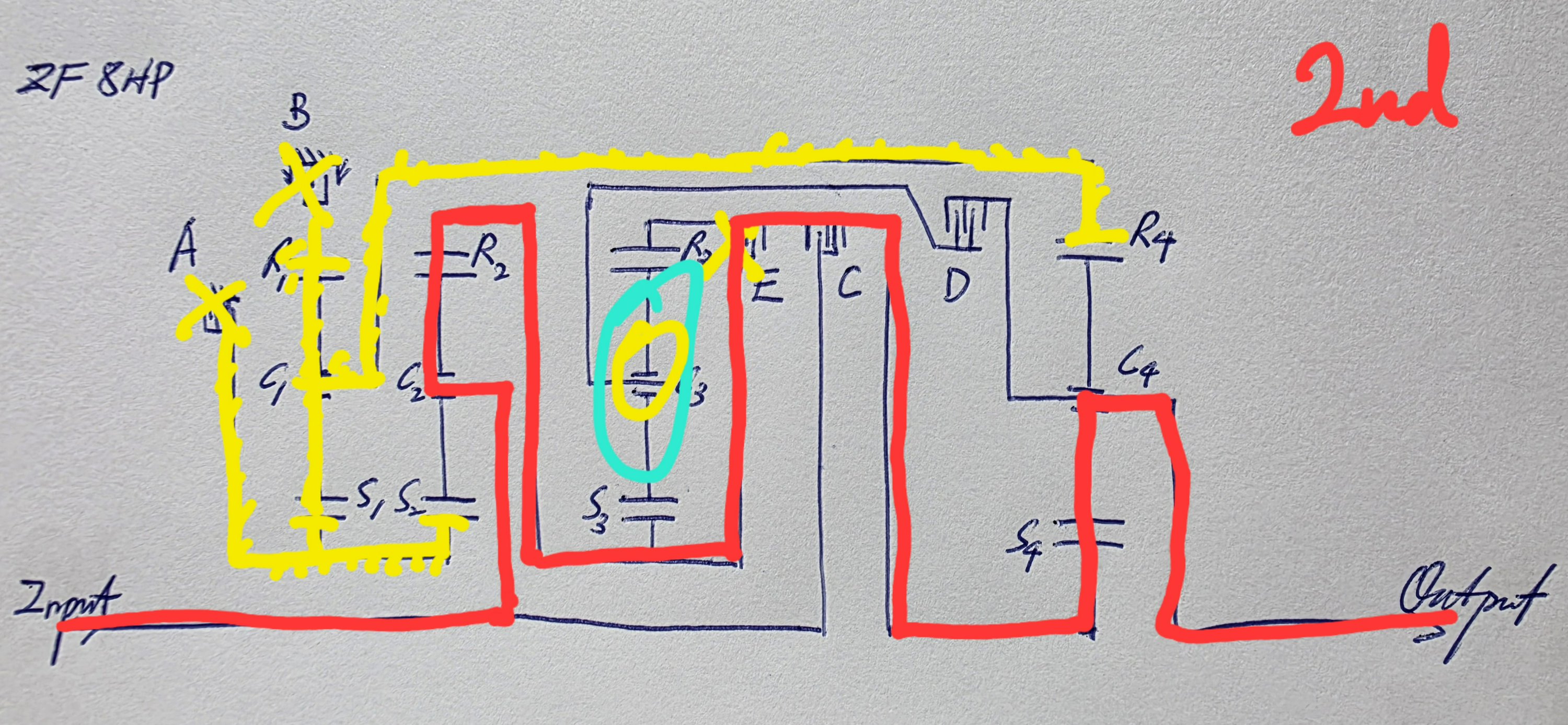

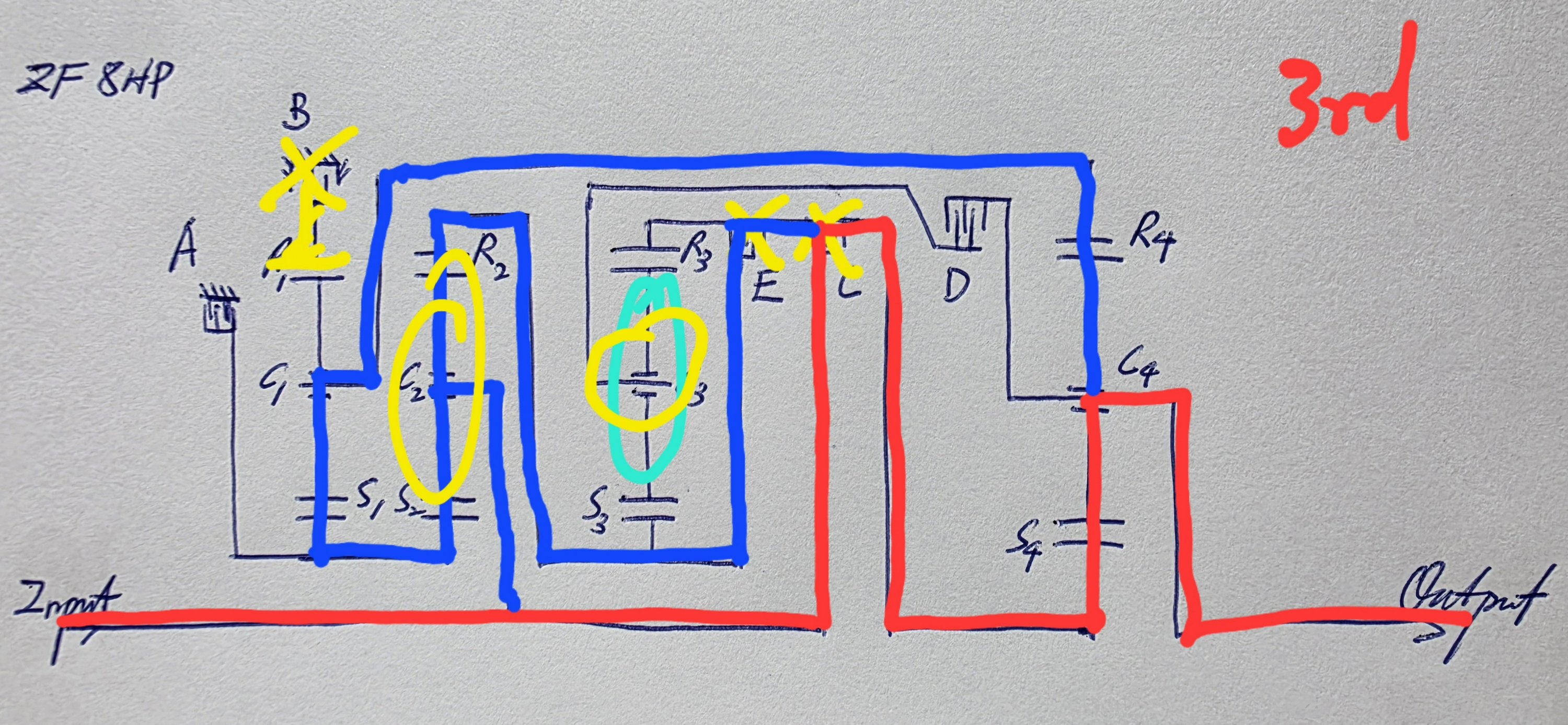

Compared to earlier designs, the ZF 8HP uses complex paths to transmit power. What is worth noting is that this transmission often locks a gearset out by feeding identical inputs to two of its elements. In the following, Red is the path where engine torque is transmitted; Blue is the “counter-holding” path; Yellow marks stationary elements and locked gearsets; Cyan marks out gears rotating parasitically.

In 1st, torque goes through C > S4 > C4. Gearsets 2 and 3 rotate without transmitting power.

In 2nd, torque goes through C2 > R2 > E > S4 > C4. Because S3 and R3 rotate at the same speed, Gearset 3 is locked but rotates without transmitting power.

In 3rd, torque goes through C > S4 > C4. As shown in the schematic, many elements are counter-holding. Notably, both Gearsets 2 and 3 rotate as units at the transmission input speed. Only Gearset 1 is reducing speed. Thus, R4 is slower than S4.

In 4th, the torque path is as shown in the schematic. The key is that Clutch E locks Gearset 3; coupled with Clutch D, this locks Gearset 4. Thus, the speed out of C1 and R2 are the same.

[CORRECTION] In 5th, torque goes through C2 > S4 > C4. Several paths are countering or restraining. S4 rotating at the transmission input speed is faster than C4, the output, which is faster than R4. [IF THE ORIGINAL ANALYSIS WERE TRUE, THIS WOULD BE AN OVERDRIVE GEAR.] The key to understand this gear is that R1 being fixed is slower than R2, while S1 and S2 share the same speed and similar (or the same, depending on versions) teeth count. So C1 (R4) is slower than C2 (input speed).

In 6th, torque goes through C > R3 > C3 > D > C4, and through C > E > S3 > C3 > D > C4. Notably, all four gearsets are locked and rotating as units. In fact, everything is rotating at the transmission input speed, even though most are not in the torque path.

In 7th, torque goes through C2 > R2 > S3 > C3 > D > C4. Counter-holding is E > R3, which is slower than S3.

In 8th, torque goes through C2 > R2 > S3 > C3 > D > C4, and through C2 > R2 > E > R3 > C3 > D > C4. Gearset 3 is locked, and the only speed increase comes from Gearset 2.

Final Words

Overall, the ZF 8HP is a great transmission held back by its need to scale. It has profound influence on subsequent automatic transmission designs, often more positive than that of its predecessor.