techXXX

Six Types of AWD Mechanisms

There is a lot of confusion and certain amount of misinformation on the mechanics of AWD systems. Today, I cover the six types of AWD mechanisms found in passenger vehicles.

There is a lot of confusion and certain amount of misinformation on the mechanics of AWD systems. What most consumers fail to understand is that branding is almost never related to the underlying mechanical construction. Today, I cover the six types of AWD mechanisms found in passenger vehicles.

Optional: Locking and LSD Mechanisms

Before delving into AWD mechanisms, it is helpful to be aware of the common locking and limited-slip mechanisms for differentials. These can be found in both front, center, and rear differentials.

- Dog clutch. Dog clutch is a type of mechanical lock that ties the two outputs together.

- Viscous coupling. Using multiple interleaved plates and a thick silicone fluid to transfer torque, viscous coupling reduces slip when the shearing of the fluid increases its temperature and thereby viscosity. It is therefore a passive system.

- Multi-plate clutch. Using multiple wet clutches controlled by a computer, MPC can reduce slip and eventually lock up the two outputs. The system can be both passive, active, and predictive.

- Torsen. Torsen LSD uses the principle that worm gears can drive worm wheels, but that worm wheels cannot drive worm gears. It actively resists wheel slip by sending more torque to the slower axle. There are multiple types of Torsen differentials.

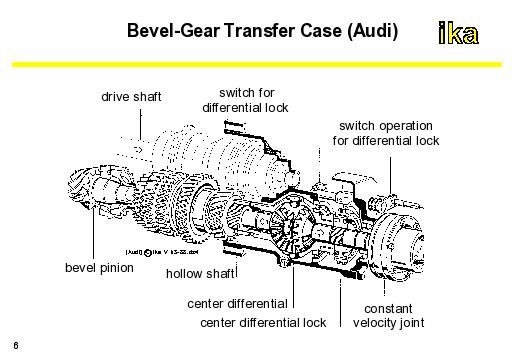

Bevel-Gear (Open) Differential

Open center differential is just like a common bevel-type rear differential. The input is fed to the bevel gear carrier, which in turn drives the two outputs via the bevel gears. It can be used in conjunction with a dog clutch or viscous coupling.

Advantages:

- Simple, cheap, reliable

- Smooth

- No wear items

Disadvantages:

- No torque biasing (50:50 only)

- Requires additional LSD for performance

Applications:

- Early Audi quattro (80s-90s)

- Subaru (pre-2000s)

- Nissan ATTESA

- Early Toyota

- Some early American SUVs

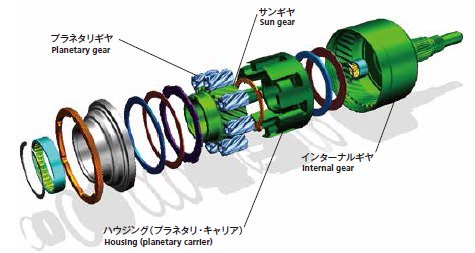

Planetary Gearset Differential

A planetary gearset consists of a sun gear, a ring gear, and several planet gears in a carrier. In a center differential, the input is fed to the planet carrier, with the sun and ring gears connected to the two outputs.

Two variations of the planetary gearset center differential exist: there is the sun + planet—planet + sun setup and the planet + sun—sun + planet setup. In the former, the input is connected to the planet carrier, and the outputs to the two sun gears. In the latter, the reverse is true. It can work well with added clutch packs.

Advantages:

- Torque biasing (based on tooth counts)

- High torque capacity (thanks to multiple planet gears)

- No wear items

- Smooth

- Compact

Disadvantages:

- Needs clutches for active control

- Cannot vary the amount of torque sent to each axle

- Heavier than bevel-gear type

Applications:

- Early Mercedes 4Matic

- Old Toyota full-time 4WD

- Land Rover

- Old Mitsubishi

- Some American trucks

Torsen Differential

There are multiple types of Torsen center differentials. Torsen type A uses cross-axis worm gears. Type B turns the worm gears parallel to the axis and achieves the same effect. Type C adopts a planetary gearset setup and uses the worm gears as the planet gears; in other words, it can be seen as a variation of the planetary gearset differential. JTEKT, the owner of Torsen, also advertises compact type C and Twin diff types, which are further derivatives.

Torsen differentials stand out in that they are active and purely mechanical. It does not need any ancillary limited-slip mechanism.

You should be aware that most of the videos showing how Torsen works uses the illustration of a Type A setup, which has had limited use in a center differential. Rather, it is usually found in front and rear LSDs.

Advantages:

- Continuous, automatic torque biasing

- Nominal torque split other than 50:50 (Type C)

- No wear items

- Smooth (Type B, C)

Disadvantages:

- Only 50:50 nominal torque split (Type A, B)

- Can only bias torque, useless when one axle loses traction completely

- Fixed torque bias ratio

- Complex and costly

Applications:

- Old Audi quattro (Type A/B)

- Most Audi quattro with ZF transmission (Type C)

- Toyota/Lexus (Type C)

- Some GM trucks (Type C)

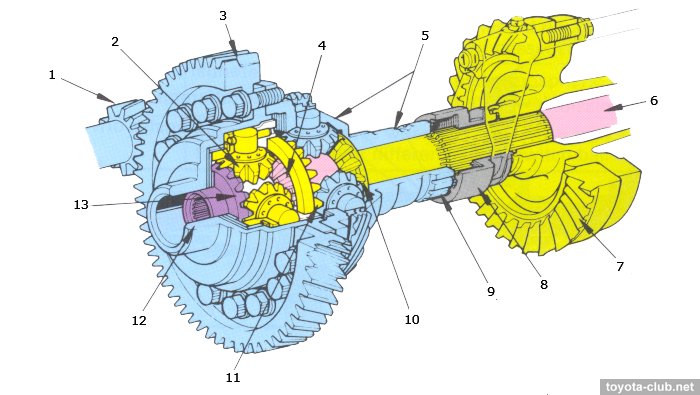

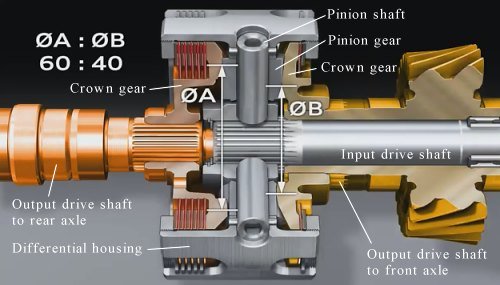

Crown Gear Differential

Audi’s crown gear differential is close in design to a bevel-gear open differential. The input drives the carrier of four spur gears, which in turn drive two crown gears for the two outputs. With crown gears of different sizes, this differential can bias torque to one axle. It is coupled with multi-plate clutches to control the torque split.

Advantages:

- Biased torque split (usually 40:60)

- Active torque managing (with clutches)

- Lighter than Torsen

- Can lock even when one axle has no traction

Disadvantages:

- Complex

- Less smooth

- Less reliable

- Has wear items

Applications:

- Some newer Audi S and RS models

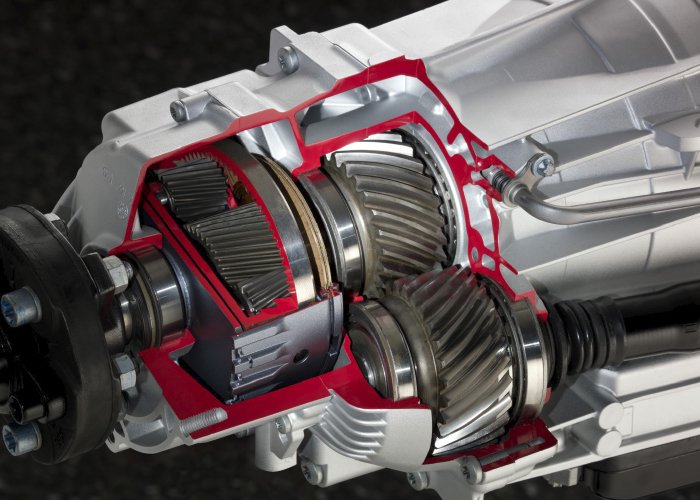

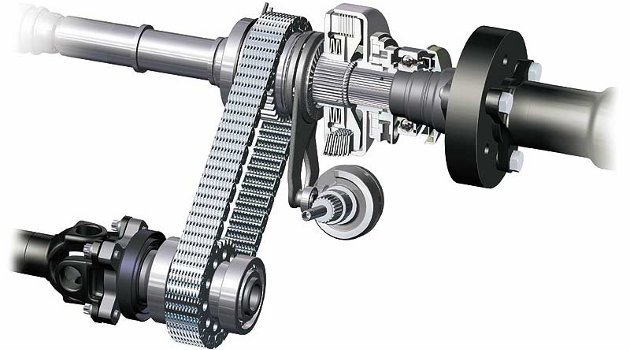

Multi-Plate Clutch Transfer Case

With MPC, some manufacturers offer AWD cars without a center differential. Instead, the transfer case resembles one found in 4WD vehicles. There are two general variations: one stays RWD until the computer engages the clutches; the other always slips the clutches all the time to send some torque to the front wheels. Sometimes, this setup may involve a chain drive.

Advantages:

- Torque vectoring

- Compact, light

- Cheap

Disadvantages:

- Fragile

- Has wear items

Applications:

- Some BMW xDrive (chain in X1-7)

- Some Mercedes 4Matic

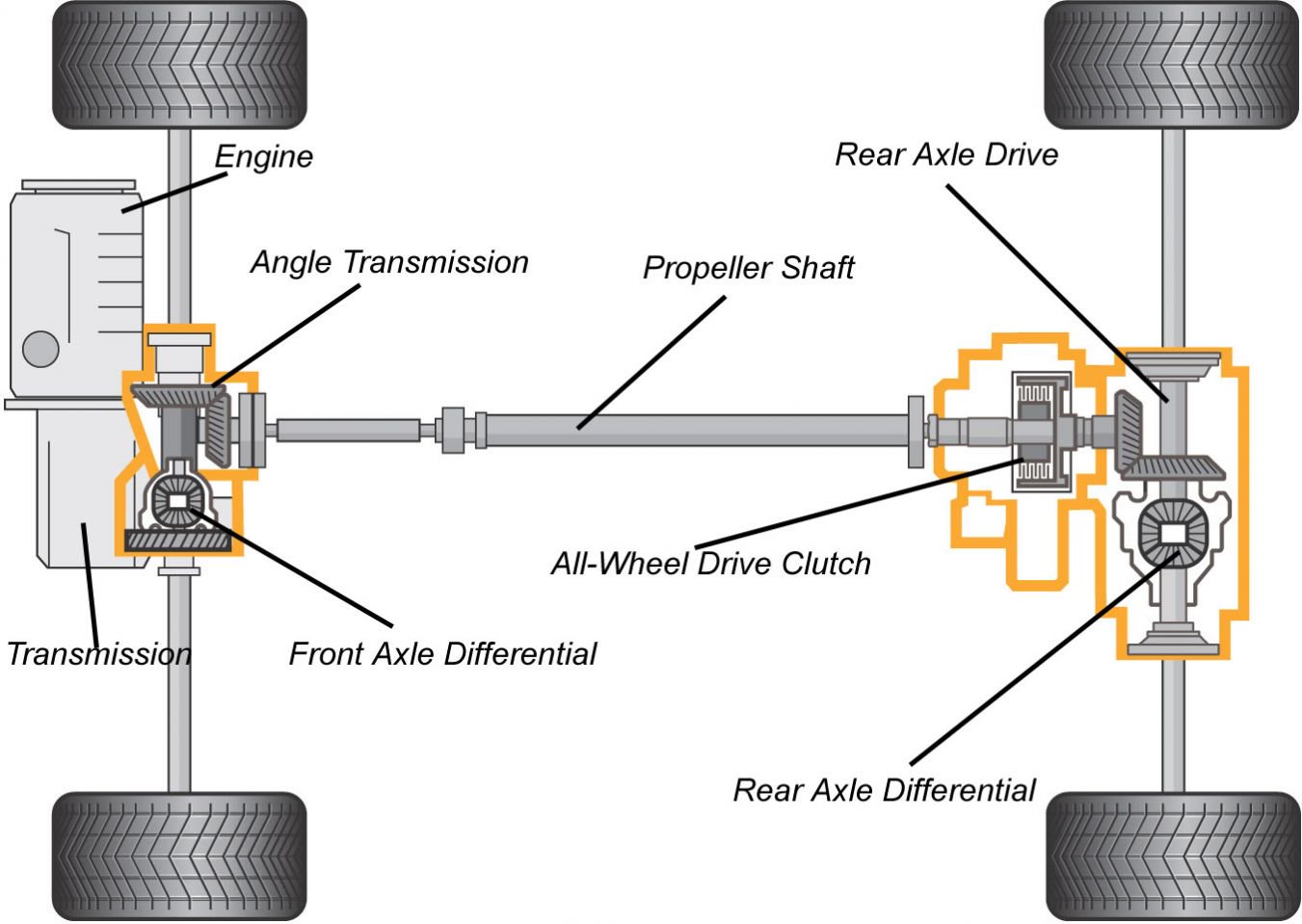

Haldex-Like MPC System

Lastly, there is the Haldex system and its variations, which also use multi-plate clutches. These are found in FWD vehicles with part-time AWD. The output to the rear prop shaft is fixed to the output to the front, meaning that they rotate at the same speed. Then, a multi-plate clutch system is located just in front of the rear differential. The computer controls the clutches to send some torque to the rear when needed. In older Haldex versions, the clutches may be slipping continually to send a little torque to the rear wheels, primarily to reduce backlash to the system.

Advantages:

- Compact, light, cheap

- Fuel economy

Disadvantages:

- Clutch wear

- Limited torque transfer capacity

- Poor performance

Applications:

- Most FWD-based AWD cars, including Audi quattro with Ultra

- Lamborghini (inverted)

- Bugatti (inverted)

Final Words

Beyond these mechanisms, electrification has made it possible to separate front and rear axles using independent power units. In my opinion, however, the best AWD is RWD with a good driver.

Ranking:

RWD > Torsen Type C > Planetary > Bevel > Torsen Type A/B > Crown Gear > Haldex > MPC TC