techXXX

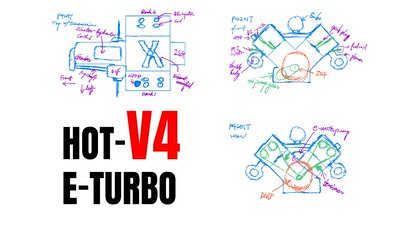

V4 Hot-V e-Turbo 2.0L Engine for Cars—Mcc 12

Today, I am introducing a unique 2.0L hot-V electric-turbo 90-degree V4 with motivations and specifications.

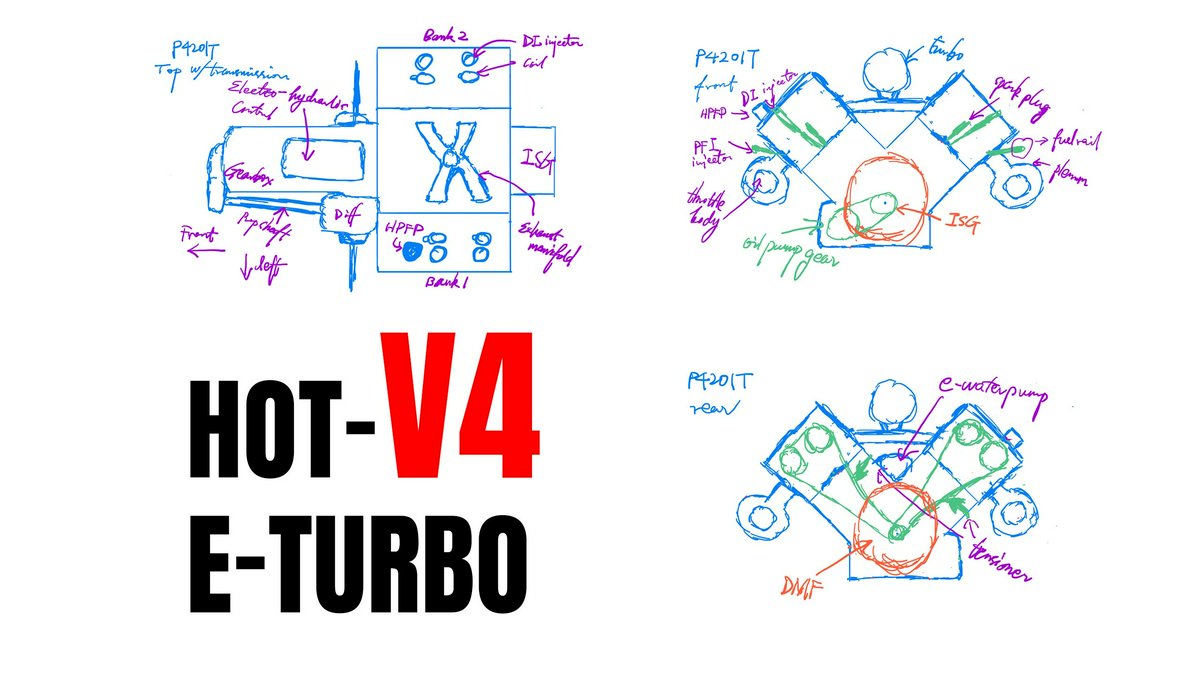

Continuing the theme of ‘My Car Company’, which lays out interesting car design ideas for enthusiasts, I am introducing a unique 2.0L hot-V electric-turbo 90-degree V4. It will carry the engine code P4201T, which stands for Petrol 4-cylinder 2.0l Mark 1 Turbo. Today, I will motivate for this engine and list its specifications. I will also explain why select key specs are chosen. Unlike it is with the 3L V12, PC301, which I examined previously, I will not delve into all the details.

Why 90-deg V4? Why hot-V? Why e-turbo?

Compared to an inline-4, a 90-degree V4 enjoys 6 key advantages:

- It has perfect primary balance, like a flat-plane inline-4, but has much better secondary balance. Thus, it runs smoothly without a balance shaft, which means simpler rotating assembly, lower center of gravity, and freer-revving character.

- We can run a reverse-flow hot-V design, which keeps the turbocharger closer to the cylinder head.

- Because it is small, we can leave generous room between the cylinders for cooling and still have a small engine. The result is more precise temperature control. That is, we can run the engine very hot for efficiency but never too hot locally to cause any damage. In comparison, modern inline-4 turbos have siamesed, or conjoined cylinders with hot spots.

- With just two crankpins and three main bearings, the V4’s crankshaft is much shorter, lighter, more rigid, and freer-revving. We can achieve higher efficiency and higher output at the same time.

- The smaller crankcase also has less windage, which further helps in efficiency.

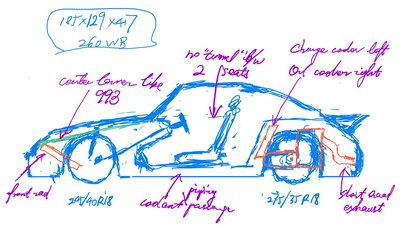

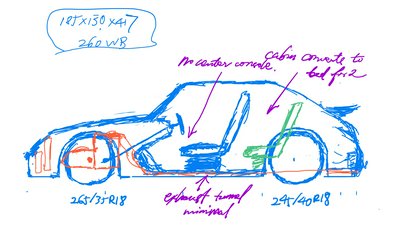

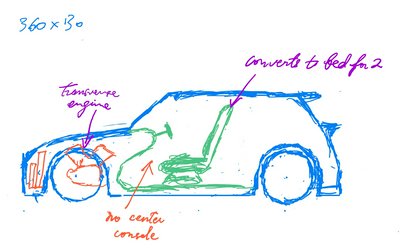

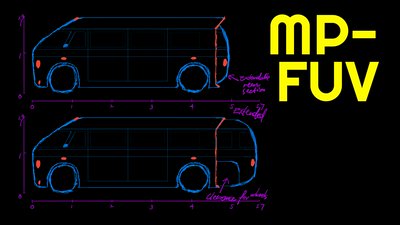

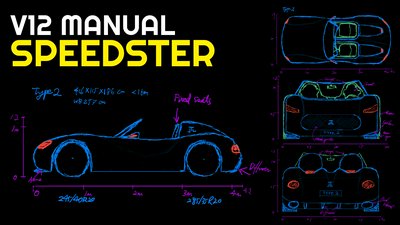

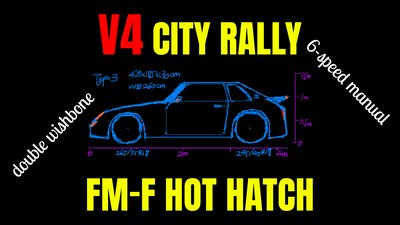

- The V4’s squarer packaging creates many unconventional mounting options. As examples, I have sketched three cars, which I will discuss one by one later. The first is a longitudinal front-mid-engine, front-wheel drive (FM-F) compact hatchback that can use double wishbone suspensions. The second is a longitudinal rear-engine, rear-wheel drive (R-R) sports car that harkens to the Porsche 993. The third is a transverse front-engine, front-wheel drive (F-F) mini hatchback. No other engine layout with this level of output can be this flexible.

Paired with an e-turbo, this V4 can match the output of the average turbocharged V6 engine while having more character.

The choice of hot-V is based on 3 considerations, which sums up to it being otherwise too complex to turbocharge a 90-degree V4:

- Hot-V makes exhaust runners incredibly short.

- Exhaust routing is very simple.

- Heat soak is less of an issue compared to hot-V6 and V8 layouts, because there is more space to direct air to cool the turbo.

Lastly, electric turbocharger is not a choice but a necessity:

- Our V4 has an uneven firing order, with pulses of 180° -> 270° -> 180° -> 90°. This makes spooling up the turbo at low RPM tricky. E-turbo eliminates this concern.

- We want to take advantage of the high-revving potential of the V4 but also make a lot of torque down low. E-turbo is the simplest solution.

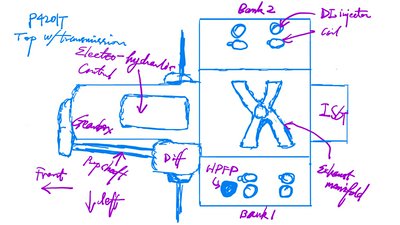

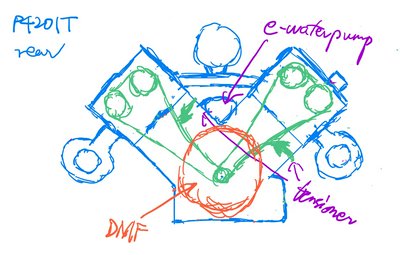

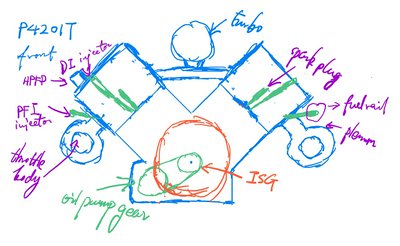

- Our hot-V turbo V4 is so flexible in terms of packaging because in the FM-R and R-R layouts we run the exhaust downpipe to the opposite side of the transmission. This means no belt-driven accessories. We solve this with an Integrated Starter-Generator (ISG), which also enables e-turbo. Indeed, we can have electric wastegate, electric VVT, electric water pumps, and electric AC compressor, all while improving efficiency and emissions.

Specifications of P4201T

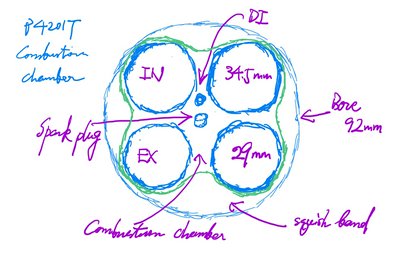

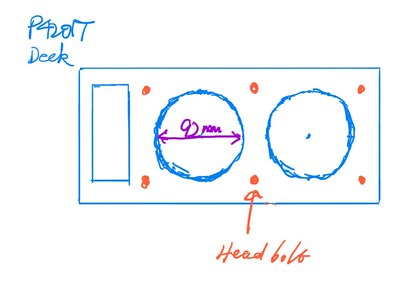

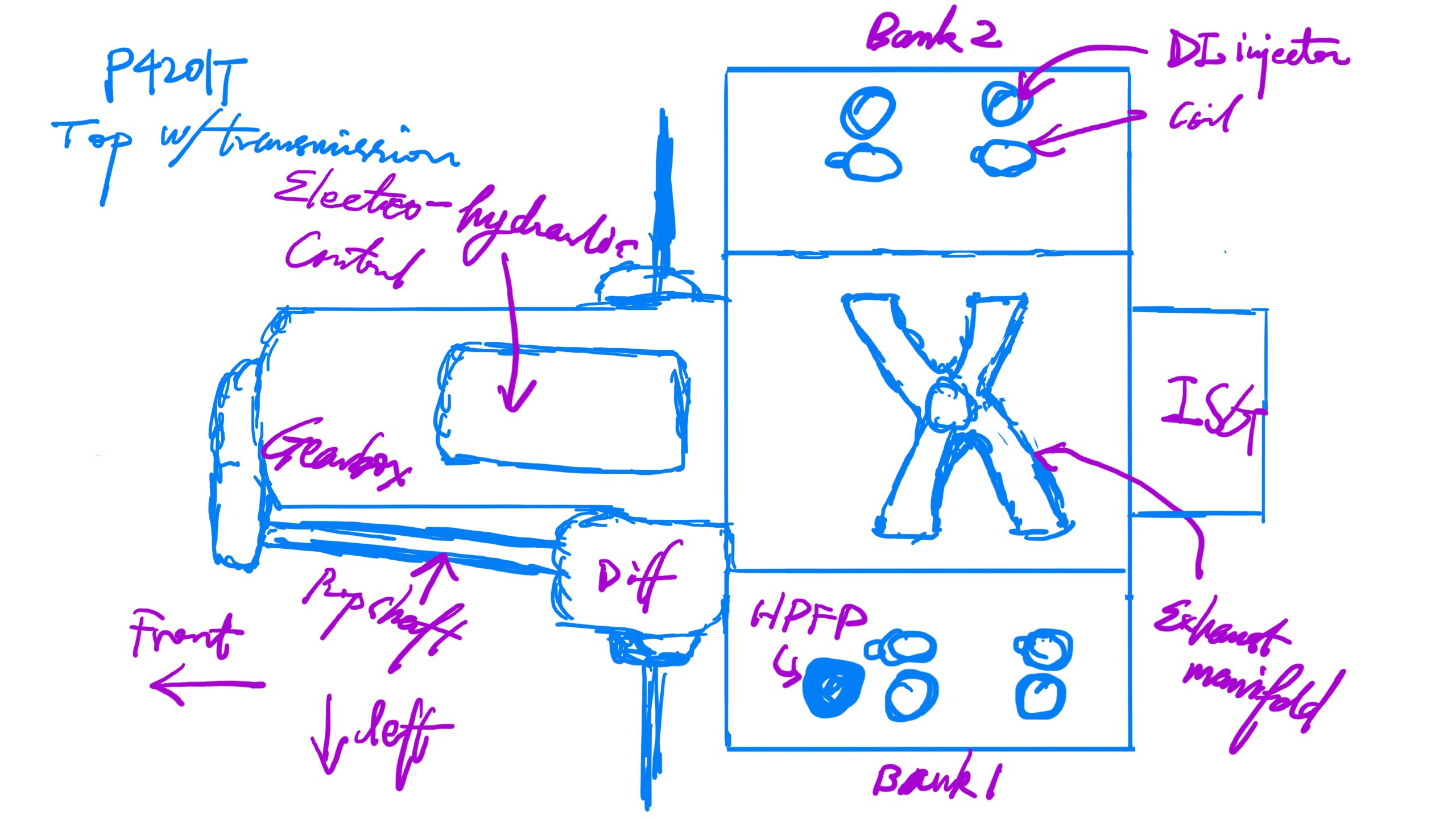

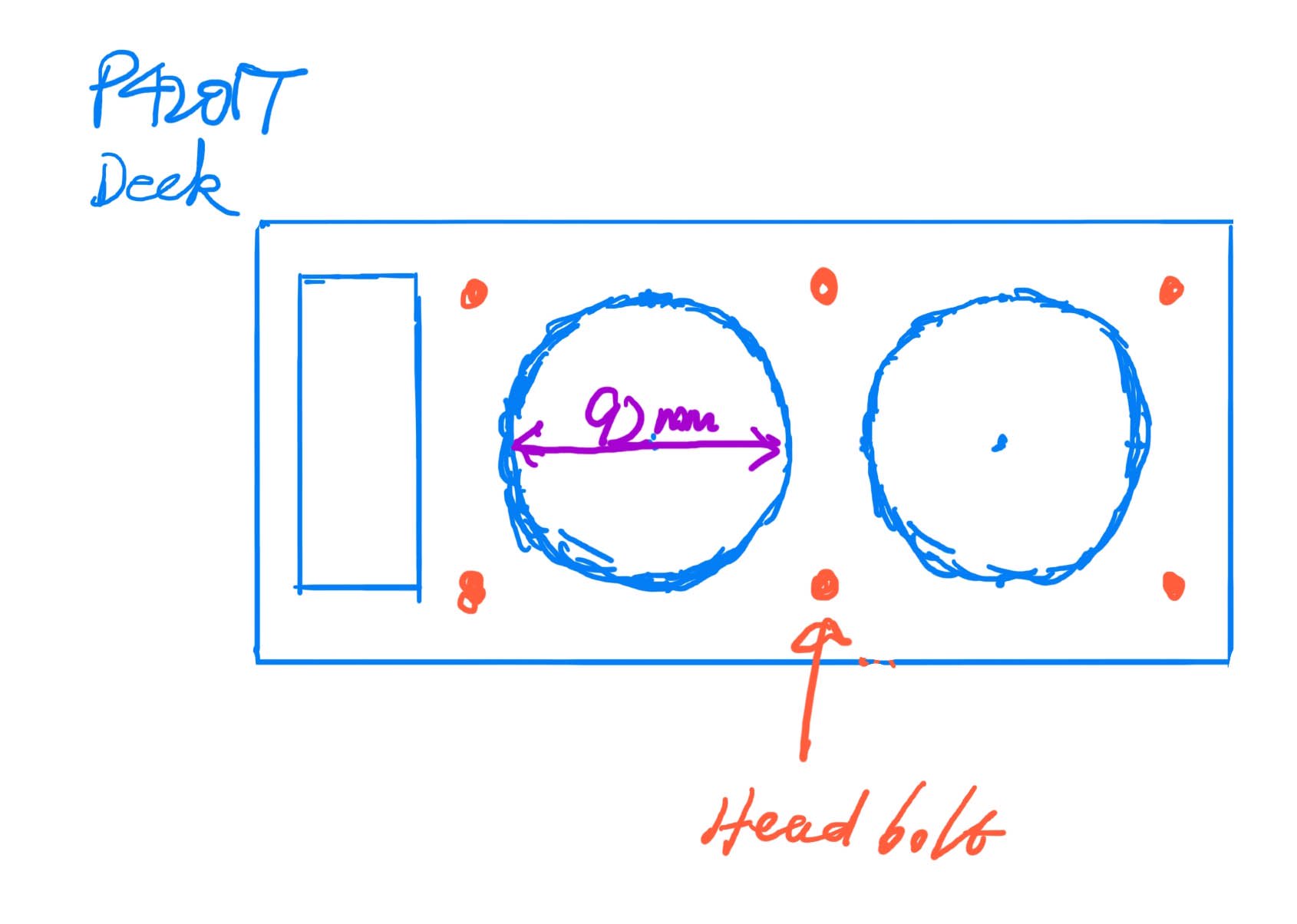

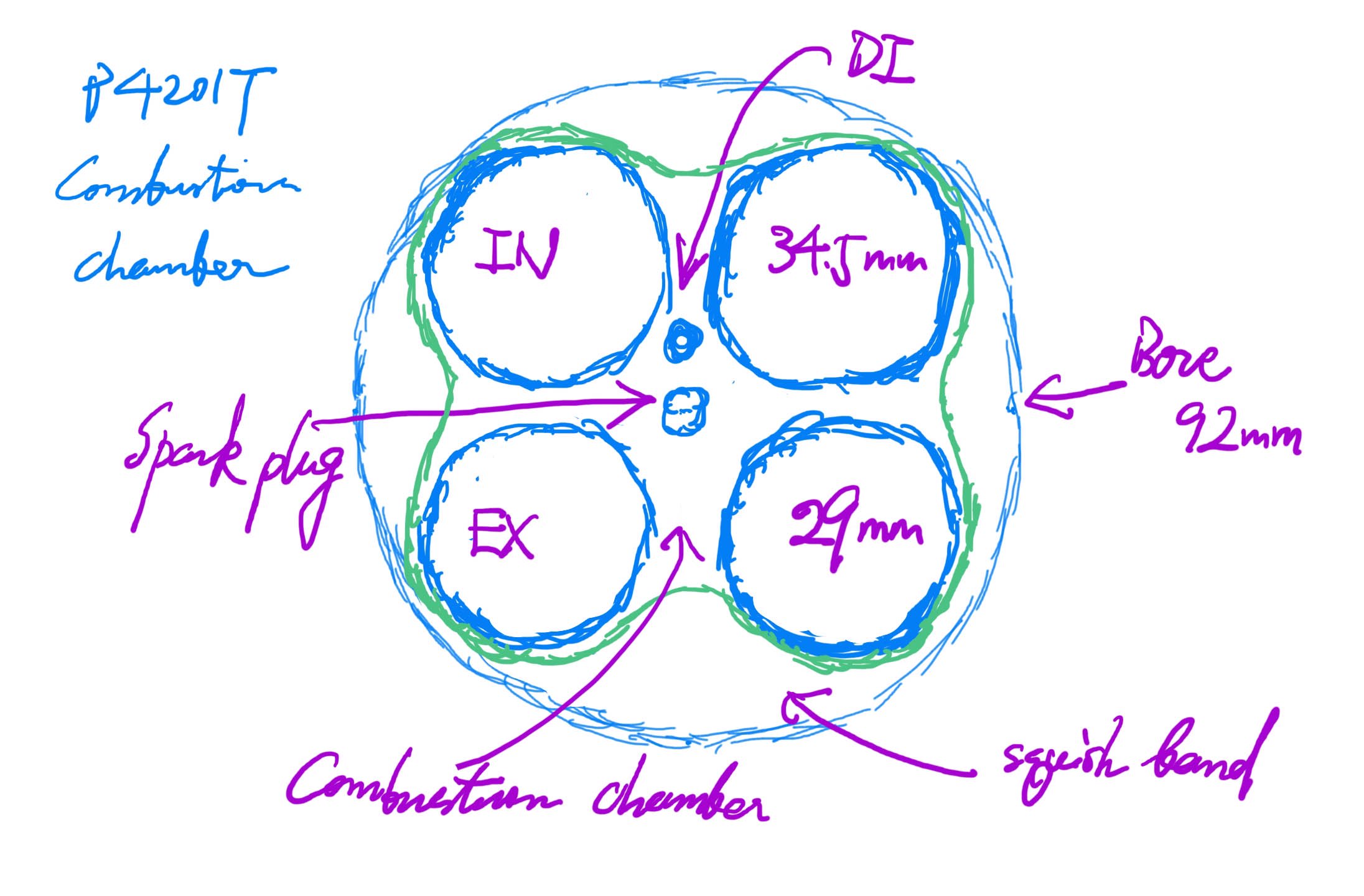

- Bore x Stroke: 92mm x 75mm => 1994cc displacement, 1.23:1 bore/stroke ratio

- Cylinder Spacing: 112mm

- Rod Length: 124mm => 1.65:1 rod ratio

- Piston Compression Height: 30mm

- Deck Height: 192mm

- Bank Angle: 90°

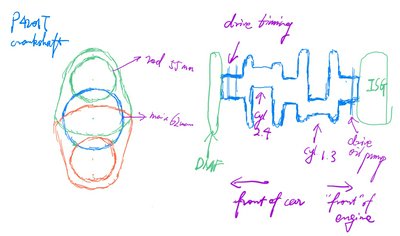

- Crankshaft: 180° (flat-plane), 3 main bearings, 4340 forged steel

- Conrod: 4340 forged steel

- Rod Bearing: 55mm (journal diameter) x 24mm, .06mm clearance

- Main Bearing: 62mm (journal) x 26mm, .06mm clearance

- Bearing Material: Tri-metal

- Block: Nikasil coated aluminum block, bedplate, waisted studs

- Water Jacket: Closed deck, 10mm between cylinders

- Piston: 4032 forged aluminum

- Engine Oil: 5W40 ideal, 5W30 from factory

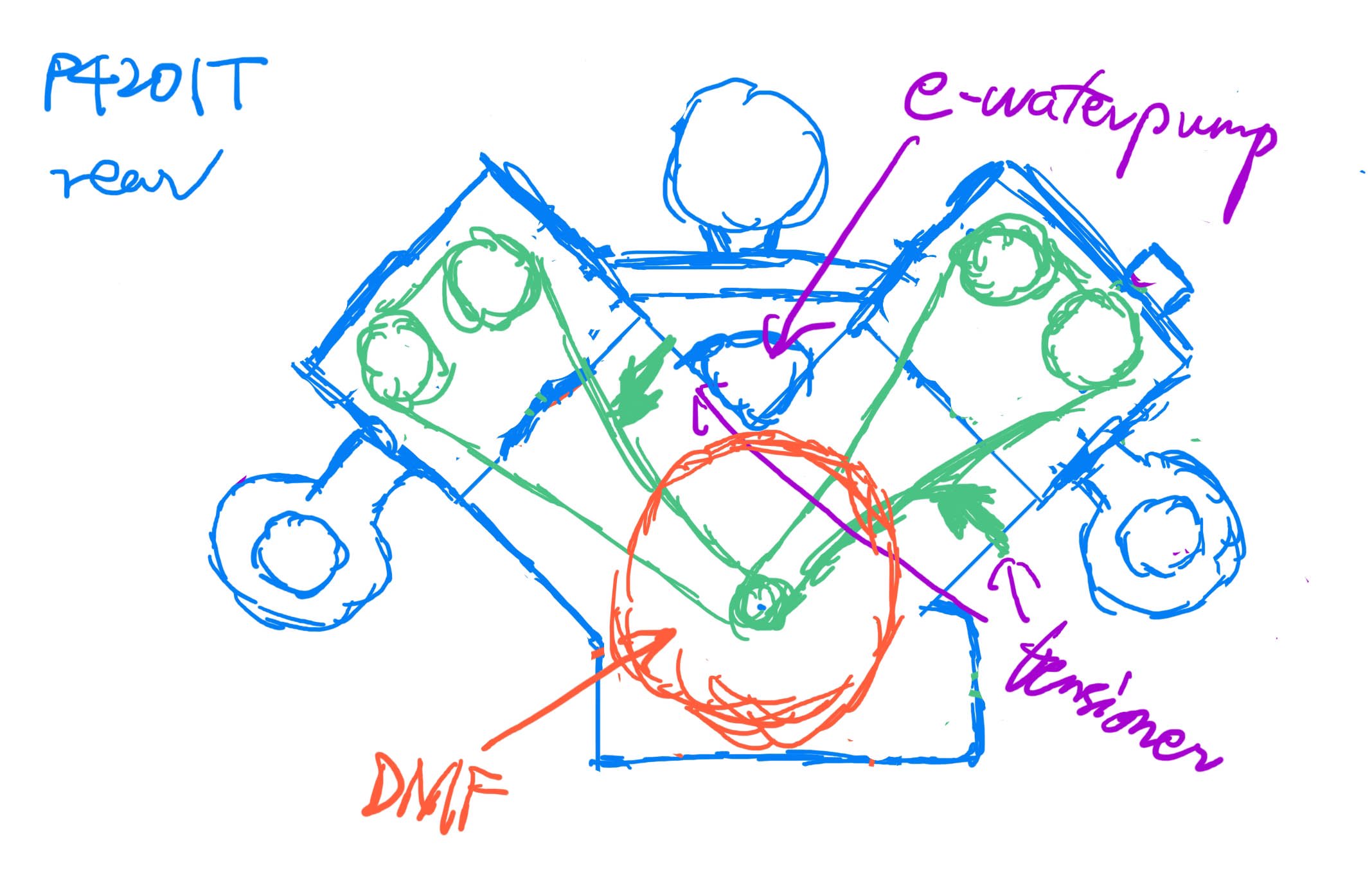

- Timing: Separate inverted tooth chains for each bank, rear mount

- Flywheel: DMF

- Cylinder Numbering: • Bank 1: 1, 2 • Bank 2: 3, 4

- Firing Order: 1-2-3-4

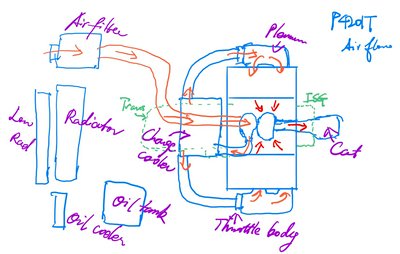

- Turbo: Single scroll e-Turbo, electric wastegate, 54mm compressor wheel

- “Mild-Hybrid”: Crank-driven ISG (at front of engine)

- Oiling: Dry sump, 2 scavenge stages + 1 pressure stage

- Compression Ratio: 9.5:1

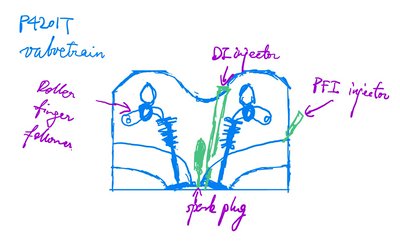

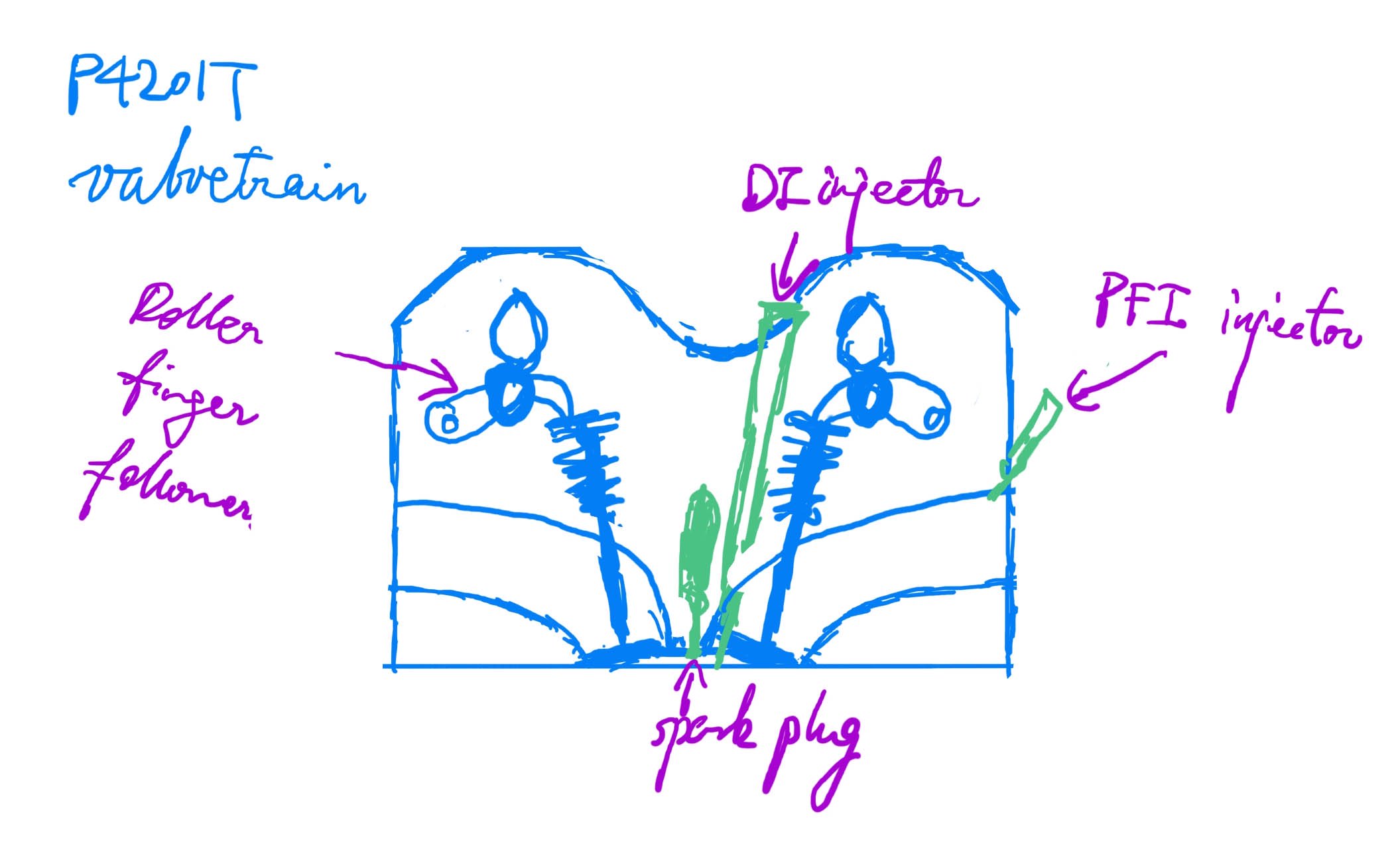

- Intake Valve: 34.5mm, 9.8mm lift, 230° duration @ 1mm

- Exhaust Valve: 29mm, 8.8mm lift, 225° duration @ 1mm

- Lifter: Roller followers

- Springs: Dual springs

- Variable Valve Timing: ±40° intake, ±30° exhaust, default LSA 115°

- Intake Runner: 150mm x 42mm ID

- Exhaust Runner: short x 34mm ID

- Fuel Delivery: DI + PFI

- Charge Cooler: Rear mount

- Redline: 8500rpm

- Target Power: 400hp to 500hp @ 7500-8000rpm

Discussion of Key Aspects

Bore, Stroke, and Cylinder Spacing

Our V4 is quite oversquare, while most inline-4 turbo engines are undersquare. This is because we can, and an oversquare engine, even in the context of forced induction, has higher power potential. A common misconception is that an undersquare engine develops more low-end torque. This is only usually true because such engines come with smaller valves that help with intake velocity. An oversquare engine paired with some form of variable valve lift (VVL) can also achieve similar low-end torque naturally aspirated. However, and this comes to a trade-off in V4, it is too uneconomical to implement VVL for just four cylinders in two banks. Thankfully, with an electric turbo VVL is less important, though we do pay for it with fuel consumption and efficiency. This means that in Standard and Eco modes we need to run the e-turbo more conservatively, if only for compliance reasons. At high RPMs, the advantage of an oversquare design becomes obvious, and our engine can breathe more freely and fully utilize the boost from that relatively large turbo.

Another drastic departure from mainstream inline-4 turbos is the relatively large cylinder spacing. Similar spacing is only found today in boxer engines such as those in the Porsche 911, and in that case largely because they need to fit 7 main bearings on a 3-cylinder-long block. Still, and as it is with the Porsche, a larger cylinder spacing affords a more rigid block and room for inter-cylinder cooling. The latter means that our engine tolerates boost much better than those inline-4s. In the end, we are still a lot more compact.

Bearing Size

The bearing sizes are the results of guesswork based on two principles. One, we have only three main bearings. Thus, they cannot be as small as those in inline engines and still match up in durability. Therefore, I have upped their diameter and width to achieve a comparable total surface area. Two, we know that mainstream automakers are using underspecified bearings that do not last for efficiency numbers. Hence, we are slightly more generous, particularly with the rod bearings.

Since our turbo V4 will not rev as high as the V12 I covered earlier, I believe that an increase in journal diameter is slightly more favorable to an increase in width, because this also increases crankshaft rigidity especially in the case of an uneven-firing, high-low-end-boost engine. Still, we need to balance diameter with width, because otherwise oil flow must be drastically higher.

Oil System

Strictly speaking, a turbocharged V4 does not need dry sump lubrication, because the revs will be lower than NA engines, a V4’s oil pan would be compact, and a V4 has lower windage than an inline-4. Nevertheless, I want to specify one to take advantage of even lower center of gravity, even lower windage, and the compatibility with piston rings with lower tensions. Dry sump also works better with our relatively large bearing diameters (and thus high bearing surface speeds).

I think a simple setup with two scavenge stages and one pressure stage is enough. We will use an air-to-oil cooler between the scavenge stages and the oil tank. For the reasoning, please check out my earlier post on the PC301 V12.

VVT

For a turbocharged engine, VVT is crucial. Retarding intake while advancing exhaust helps catalyst light-off and reduces cold-start hydrocarbon emissions. In the opposite direction, we get better cylinder fill and higher exhaust energy for more power. By adjusting the overlap, we can get the effect of what is called “internal EGR”, too, for knock and emission control.

Theoretically, with only intake VVT we may be able to get most of the advantages while cutting half the complexity. The exact power levels that our V4 can reach in this setup need to be verified.

Also please note that the valve sizes listed are based on guesswork instead of engineering, which should be done before settling on the optimal design. So it is with the valve durations.

Dual Fuel Injection

Turbocharged engines benefit greatly from dual fuel injection. At cold start and high load, we rely primarily on DI. In most scenarios, we run the engine with PFI. This strategy is different than how mainstream, notably German, automakers use dual injection. In essence, theirs are DI engines with PFI as an afterthought, while ours is a PFI engine that uses DI selectively for emissions and knock control. A result of this difference in strategy means that our engine feels smoother and livelier, more like a petrol instead of a diesel.

Intake and Exhaust Runners

The size of the intake runners is less important in the context of forced induction than it is in an NA engine but not irrelevant. We want an intake runner length that offers good drivability and top-end power, because we want to put our V4 in compact street-going cars, and because our e-turbo masks any spool-up deficiencies. Thus, we target a 150mm length with 42mm diameter. There will be a small, 1L plenum behind a 60mm throttle body on each side. The two intake manifolds should be made of plastic.

For exhaust runners, we run them as short as possible towards the 100mm end, though physically it would have to be longer. In terms of diameter, we want velocity. A 34mm diameter is about right. The exhaust manifold should be made of 321 stainless steel.

Needless to say, all intake and exhaust runners should be length-matched, and their final designs simulated and tested in labs.

Notable Concerns

While the V4 has deep potentials, there are a couple of concerns: First, while it has been extremely successful and loved in motorcycles in naturally-aspirated form, whether the 3-main bearing design and high low-end torque are compatible remains to be proven. Second, with two cylinder heads, the V4 has a notable, though not excessive, cost disadvantage compared to an inline-4. Three, the advantages of a hot-V turbo V4 may not matter in the real world. Indeed, the Porsche 919 Hybrid remains the only modern V4 turbo application.

If the V4 turbo turns out to be viable, I believe it is ill suited to larger, heavier cars or hybrids. Larger cars need the overlapping power pulses of more cylinders. Heavier cars demand the stoutness of a larger rotating assembly. Hybrids pair better with the cheaper inline-4 layout. Rather, this V4 would shine in compact cars with unique characters. In the following posts, I will go over the general design of three such examples.

Gallery: Mcc 12 V4

XXX