techXXX

Evolution of the Mercedes 6-Cylinder Diesel

Today, I go over the construction, performance, reliability, and applications of six Mercedes 6-cylinder diesel engines. I also rank them into three tiers.

Mercedes owes much of its reputation in quality to its diesel engines in passenger cars. Today, I go over the construction, performance, reliability, and applications of six Mercedes 6-cylinder diesel engines. I also rank them into three tiers.

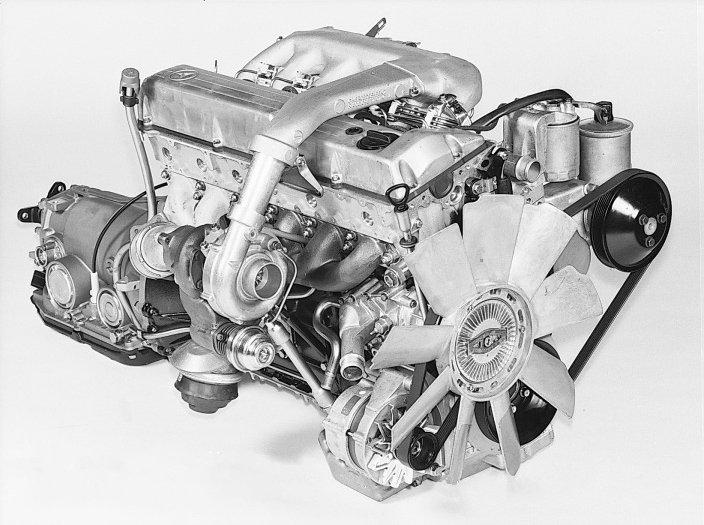

OM603

- 1986-1997

- 3.0L / 3.4L L6, 87x84mm / 89x92.4mm, 22:1

- SOHC, NA or Turbo (no intercooler), indirect mechanical injection

- Cast iron block, closed deck, forged crank

- 300D, 350D

The OM603 was the first post-war 6-cylinder diesel engine in a passenger car by any manufacturer. It has a conservative SOHC design with mechanical inline fuel injection that is mechanically controlled. The pump and the camshaft are driven by a duplex timing chain. The OM603 came in several variations, including naturally aspirated ones. The turbocharged version lacked an intercooler.

The OM603 set a milestone with superb smoothness, durability, and efficiency. However, it is known to have head issues, with the aluminum engine head prone to cracking when overheated. The 3.5L had head gasket and rod bearing issues, too.

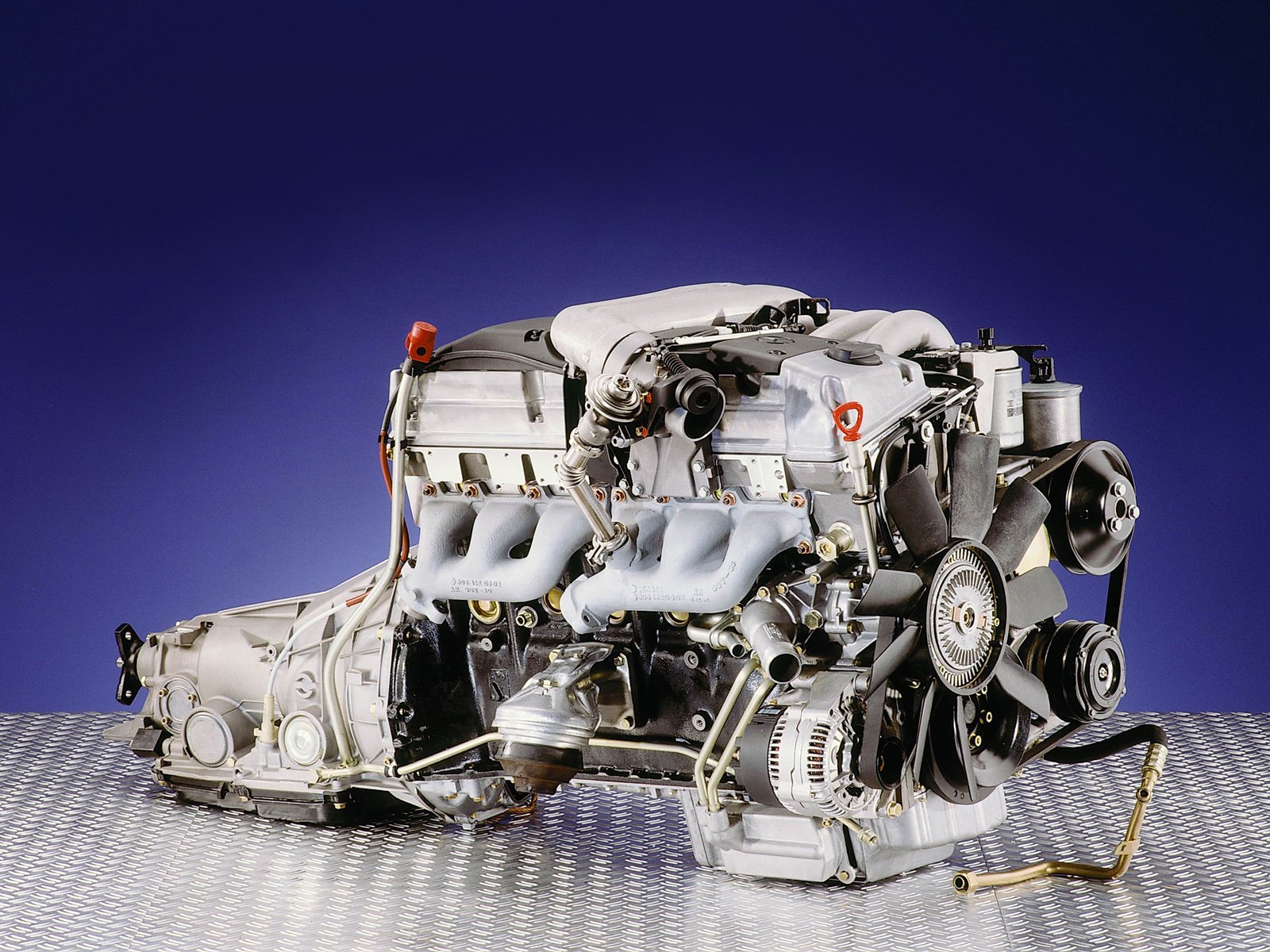

OM606

- 1993-2001

- 2.9L / 3.0L L6, 87x84mm, 22:1

- DOHC, NA or Turbo, indirect mechanical injection (electronic control)

- Cast iron block, closed deck, forged crank

- 300D

The OM606 was a major step forward in design. It has a DOHC head and mechanical inline fuel pump that was electronically controlled. While some OM606 variants were still naturally aspirated, the turbocharged version came with an intercooler, and the turbo was more responsive and has less lag.

The turbocharged OM606 has good performance and exceptional reliability. It is also considerably more efficient than the OM603. Today, it is considered one of the best passenger diesel engines ever and remains one of the favorites of diesel engine builders. Its inline fuel pump makes upgrading for high power considerably easier than common rail diesel systems.

OM613

- 1999-2003

- 3.2L L6, 88x88.3mm, 18:1

- DOHC, Turbo, CDI

- Cast iron block, closed deck, forged crank

- 320 CDI

The OM613 was the first Mercedes inline-6 to feature common rail direct injection, and it adopted variable geometry turbocharger. Mercedes also lowered the compression ratio to 18:1, probably to reduce NOx emissions. These changes made the OM613 cleaner and more powerful; however, it was a step down in reliability and tunability.

OM648

- 2002-2006

- 3.2L L6, 88x88.3mm, 18:1

- DOHC, Turbo, CDI

- Cast iron block, closed deck, forged crank

- 320 CDI

The OM648 was a refinement of the OM613 that improved efficiency, reliability, and performance. It uses the second-generation Bosch common rail injection system and features an improved EGR system. With particulate filter installed in some markets, it was also compliant with Euro 4 emissions standards. Other updates include better oil cooling, head breathing, and NVH management.

While the OM648’s jump in performance was modest, the newer engine is superior through and through. More important, it remains the last reliable Mercedes diesel engine in passenger cars. Thanks to its relatively simple electronic controls, the OM648 is a great platform for engine building.

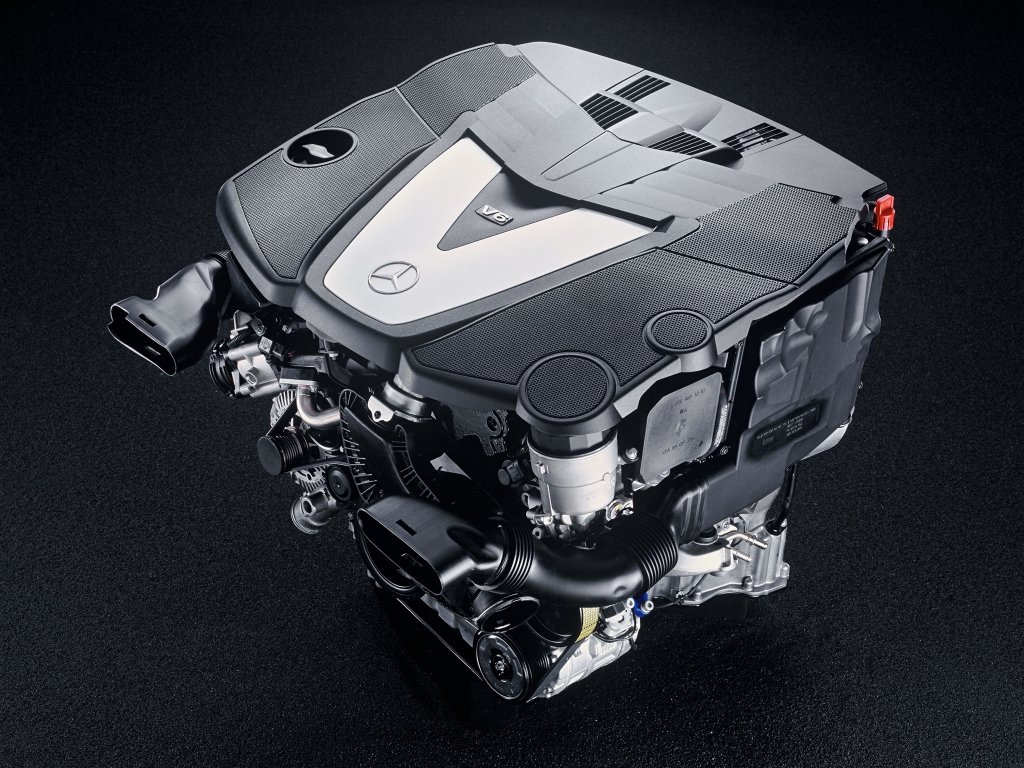

OM642

- 2005-2020

- 3.0L V6 (72°), 83x92mm, 18:1

- DOHC, Turbo, CDI

- Aluminum block, wet liner (-2014) / NANOSLIDE (2014+), open deck, cast crank

- 280 CDI, 300 CDI, 320 CDI, 350 CDI, 350d

The OM642 was an exercise in complexity. It was Mercedes’ first and only diesel V6. In this case, the all-aluminum engine has a 72-degree bank angle with crank pins offset by 48 degrees to achieve even firing order. Along with an aluminum crankcase, Mercedes also made it an open deck design with cast iron wet cylinder liners. From 2014, this was replaced by NANOSLIDE arc spray iron lining. To save cost, and because a V6 is shorter, Mercedes chose to give the OM642 a cast crankshaft. Other notable “features” include variable geometry turbocharger and in later production units urea injection. Out of necessity, the OM642 has a counter-rotating balance shaft.

The OM642 is significantly less reliable than its predecessors, worse than other German diesel engines of its time. It is also known to be less efficient and less drivable than the OM648. The engine is implicated in diesel emissions cheating schemes.

OM656

- 2017-

- 3.0L L6, 82x92.4mm, 15.5:1

- DOHC, Seq twin turbo, CDI

- Aluminum block (NANOSLIDE), open deck, forged crank, steel piston

- 350d, 400d, 450d

The OM656 is the latest and insanely complex inline-6 diesel from Mercedes. Its cylinder walls have NANOSLIDE coating, and Mercedes had the good sense to come back to forged crankshaft. What is interesting is that the OM656 also uses flat steel pistons instead of conventional stepped aluminum pistons. This helps the engine to reduce its compression ratio to petrol-like 15.5:1. The OM656 is also the first Mercedes 6-cylinder diesel to have variable valve timing, a system shared with other current Mercedes 4- and 6-cylinder modular petrol and diesel engines. This means that the simplex timing chain is located at the rear of the engine.

The OM656 utilizes two turbochargers in series, with the first, smaller one being the variable-geometry variant. It uses a water-cooled charge air cooler instead of the more traditional air-to-air intercooler. Other complexities include multi-way EGR system and convoluted exhaust emissions systems.

Needless to say, the OM656 is significantly more advanced and efficient than its predecessors. However, weaker internals and complexity depict a less rosy picture when it comes to overall ownership cost and experience.

Tier List

Tier 1: OM606, OM648

Tier 2: OM603, OM613

Tier 3: OM642, OM656

Tier 2: OM603, OM613

Tier 3: OM642, OM656