techXXX

Understanding the ZF 6HP 6-Speed Automatic Transmission

The ZF 6HP can be considered the world’s first modern automatic transmission, influencing all future models with a series of conscious trade-offs. Today, I analyze the advantages and trade-offs of the ZF 6HP and delve into how its gear train works.

Published by Dr Jiulin Teng on 29 Dec 2025

Keywords: transmissionzf

Debuted in 2000, the ZF 6HP was the world’s first 6-speed automatic transmission for passenger vehicles. It can also be considered the world’s first modern automatic transmission, influencing all future models with a series of conscious trade-offs, and making them all less reliable in the process. Today, let us analyze the advantages and trade-offs of the ZF 6HP and delve into how its gear train works.

By contrasting this analysis with those of the Aisin 8-speed and the Mercedes 7G-Tronic, which are closer in many design aspects, and with those of the ZF 8HP and Mercedes 9G-Tronic, which are less so, we can understand the evolution of modern automatic transmissions.

Advantages

1. Scalability. The ZF 6HP is highly scalable. Originally, it was available as the 6HP19, 6HP26, and 6HP32, with the two trailing digits denoting the diameter of the input shaft. In 2007, the second generation was introduced as the 6HP21 and 6HP28, though their input shafts remained 19mm and 26mm respectively. Beyond internal sizing differences, ZF also used torque converters of different sizes. This is all made easier as ZF kept the friction elements away from the gears. It is, however, not an innovation, since all older transmissions had this design; other manufacturers moved friction elements closer to the elements that they control so that the transmission could be stronger mechanically.

Trade-Offs

1. Internal Mechatronics. The ZF 6HP was the first mass-produced automatic transmission to have its computer (TCU / TCM / ETC as referred to by different manufacturers) inside the transmission housing. Coupled to the valve body and with all sensors on the same board, this computer is submerged in transmission fluid and subject to heat, vibration, and contaminants. Before the ZF 6HP, transmission computers rarely failed; after the 6HP, it became common, especially in non-Japanese models.

2. Bushing. In order to make the transmission light, compact, and cheap to produce, ZF used many bushings where ordinary transmissions would have bearings. These bushing wear out much faster. In the end, the ZF 6HP still is not lighter nor more compact than the stronger Mercedes 7G-Tronic, because Mercedes actually added cost to make its transmission lighter. Fortunately, it is the one cost-cutting philosophy that has not caught on.

3. TCC Slippage. The ZF 6HP was also the first mass-produced automatic transmission to continually slip its torque converter lock-up clutch (TCC). I have talked about this previously and will avoid repeating myself now.

4. Clutch-Heavy Design. The ZF 6HP works clutches A and E hard. This is in stark contrast to the Mercedes 7G-Tronic, which consciously avoids sending torque through its clutches in lower gears.

Gear Train

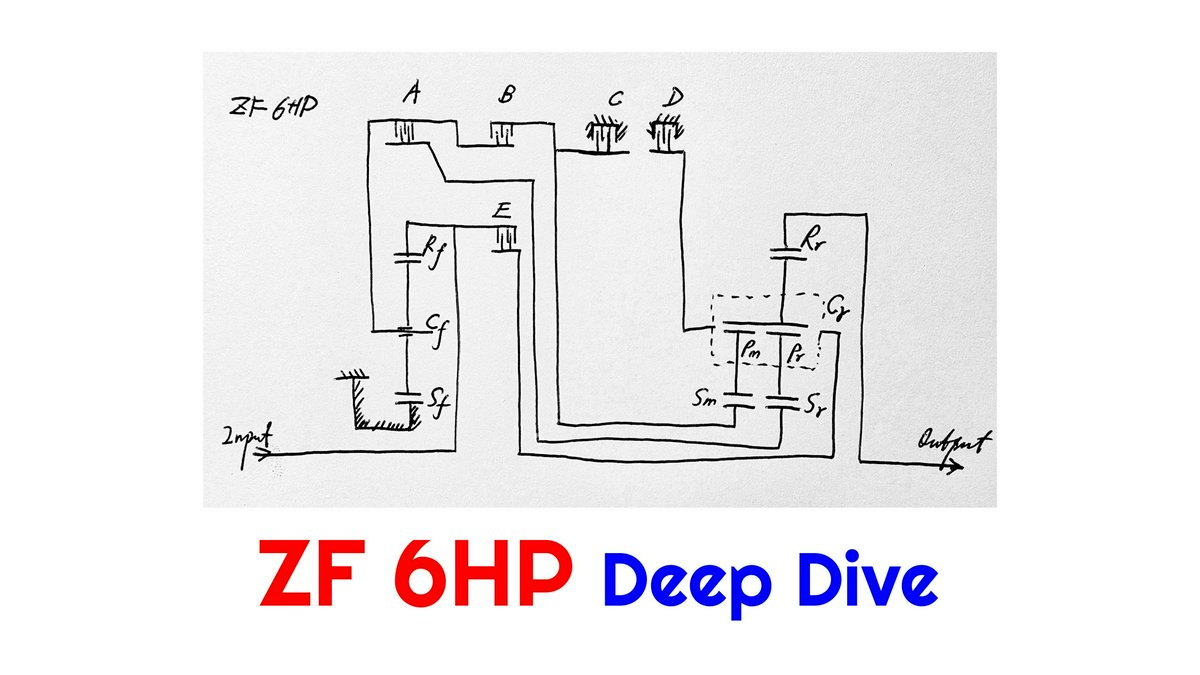

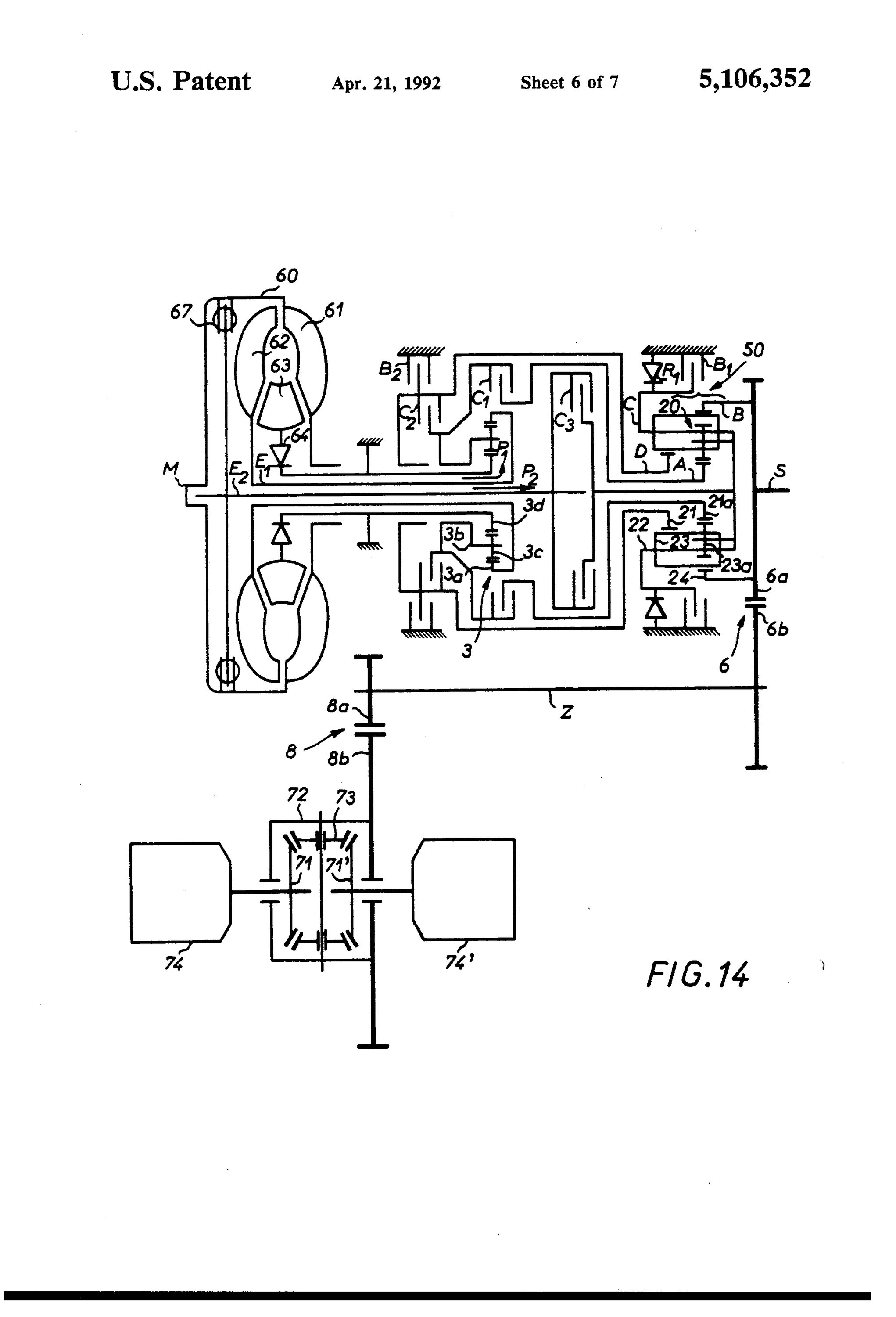

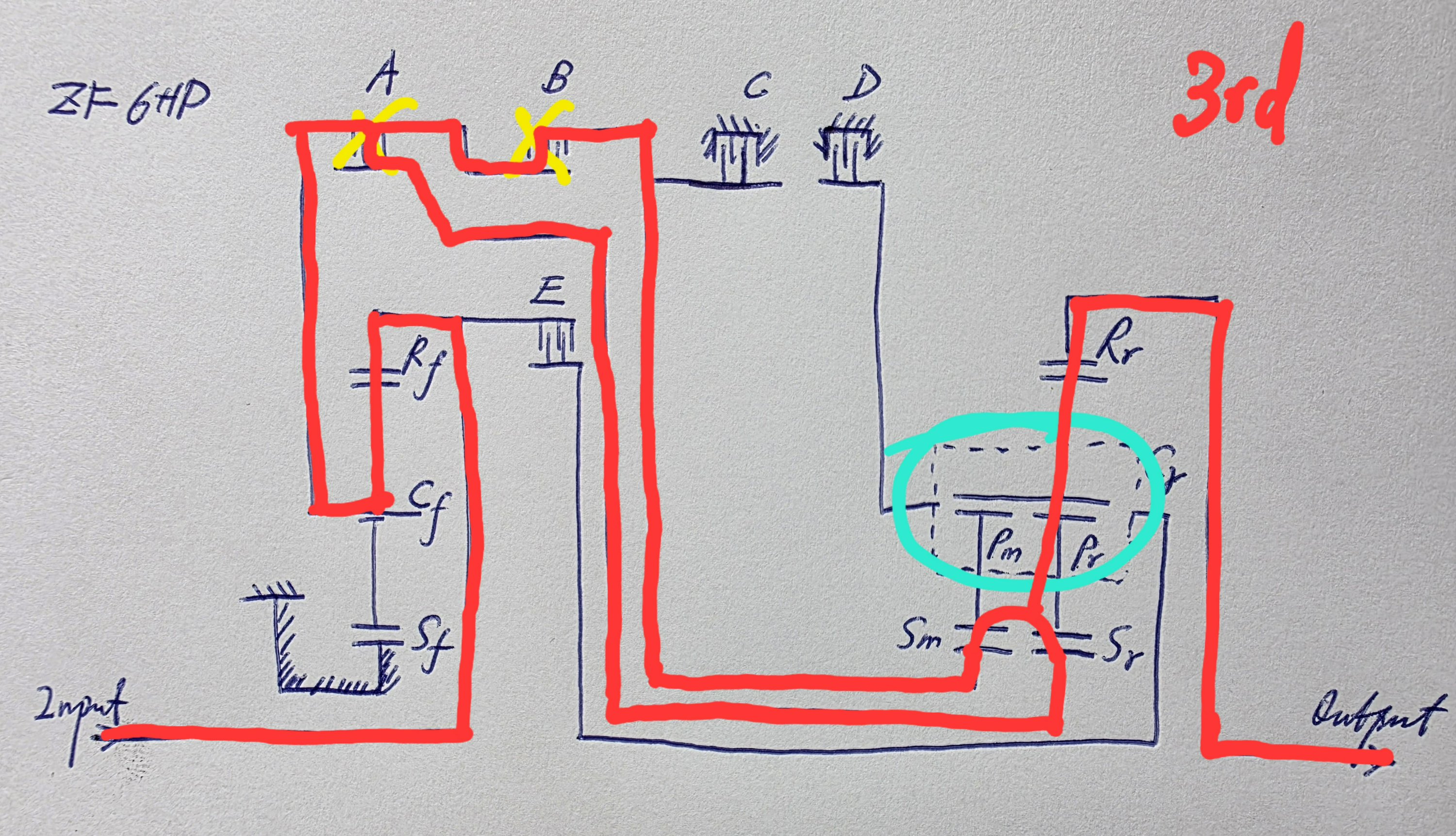

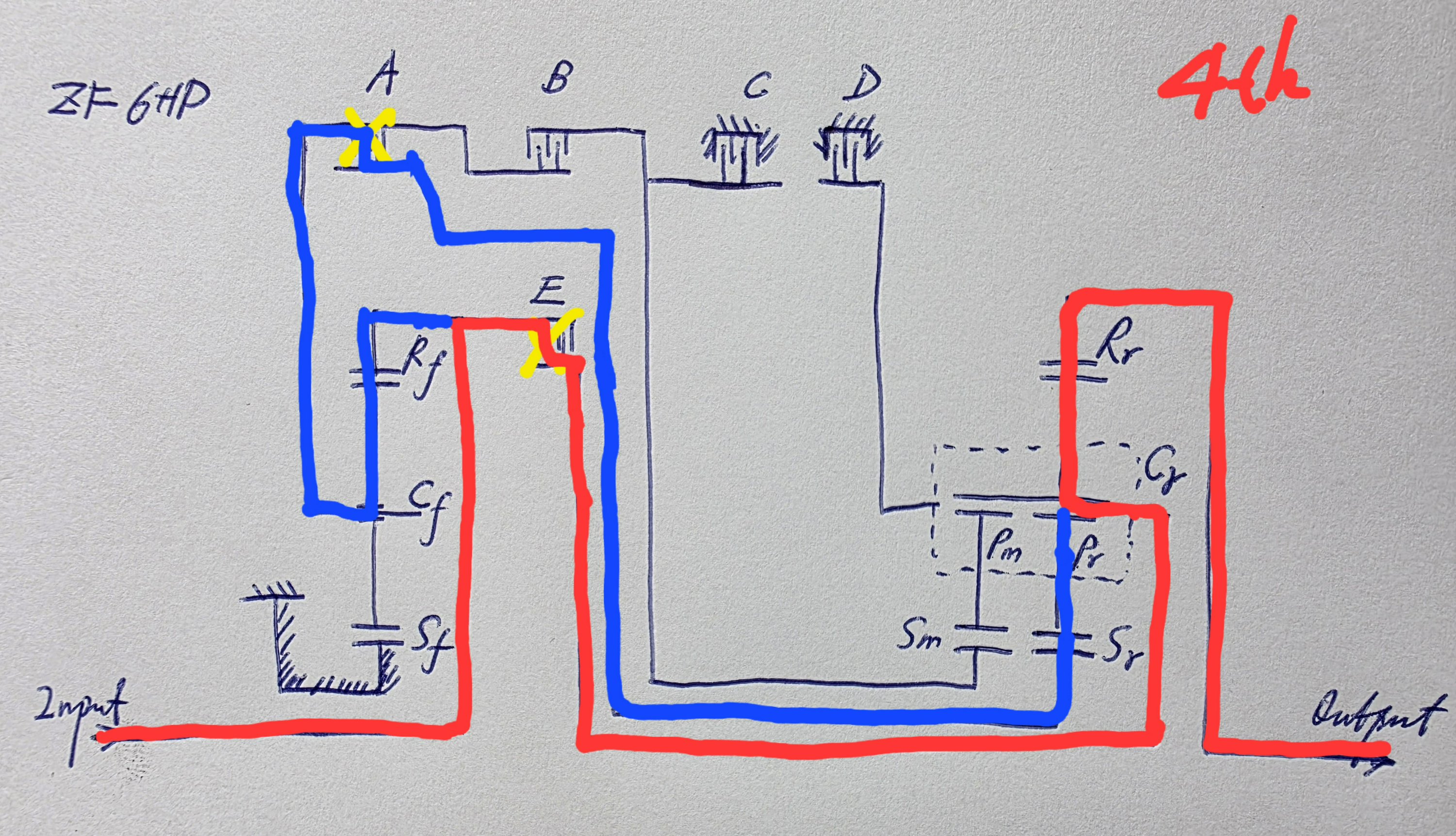

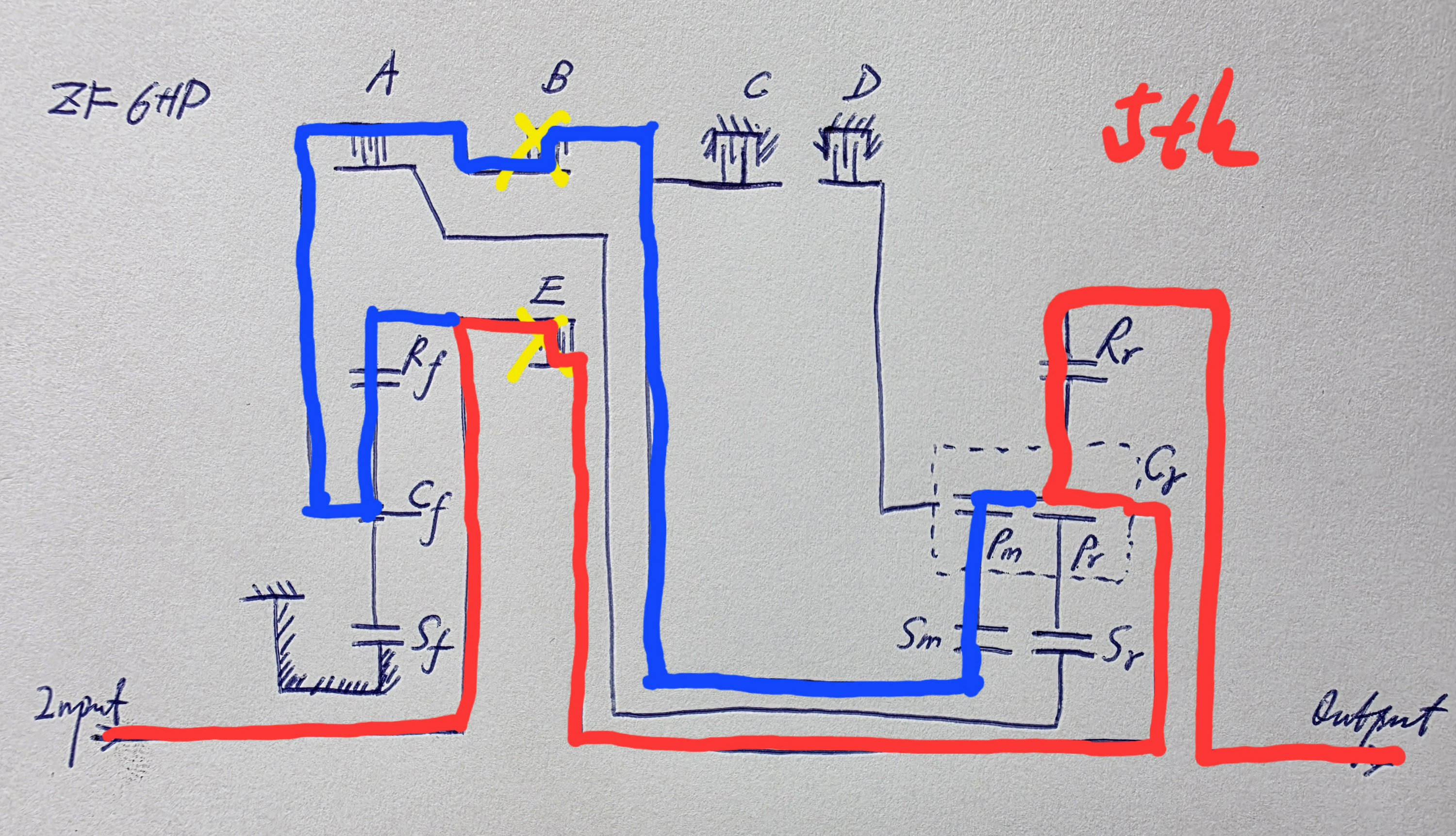

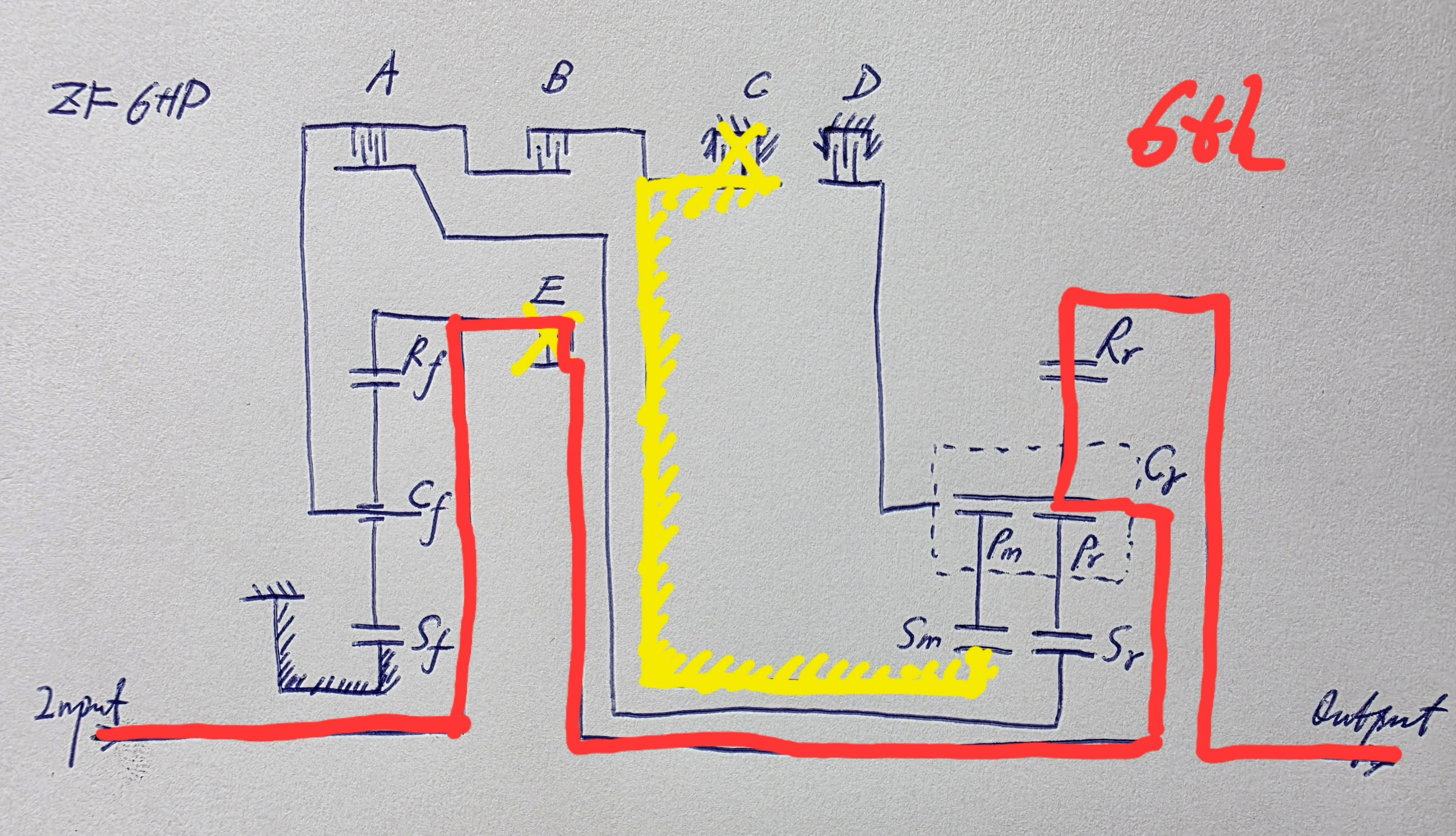

Now let us move on to the gear train schematic, which was drawn by me. Friction elements A, B, and E are the clutches; C and D, the brakes. Sf, Sm, and Sr are the sun gears; Cf and Cr, the planet carriers; Rf and Rr, the ring gears; and Pm and Pr, the short and long pinons inside the rear planet carrier. Several points are worth noting:

1. This is the design patented by Lepelletier in 1992, US Patent No 5,106,352. The difference is that Lepelletier had a one-way clutch, which found its way into the modified version in the Toyota–Aisin AA80E. The one-way clutch would have improved 1-2 shift. The ZF 6HP just used clutch D, which is needed for reverse, to reduce cost.

2. Many say that the ZF 6HP was innovative for its gear train design. However, even in the 1990s, many who saw the Lepelletier design figured out how to get 8 gears, as adopted by the Aisin, with the same simple planetary + Ravigneaux gearset layout. If you do not understand the Ravigneaux gearset, please check my previous video.

Torque Paths

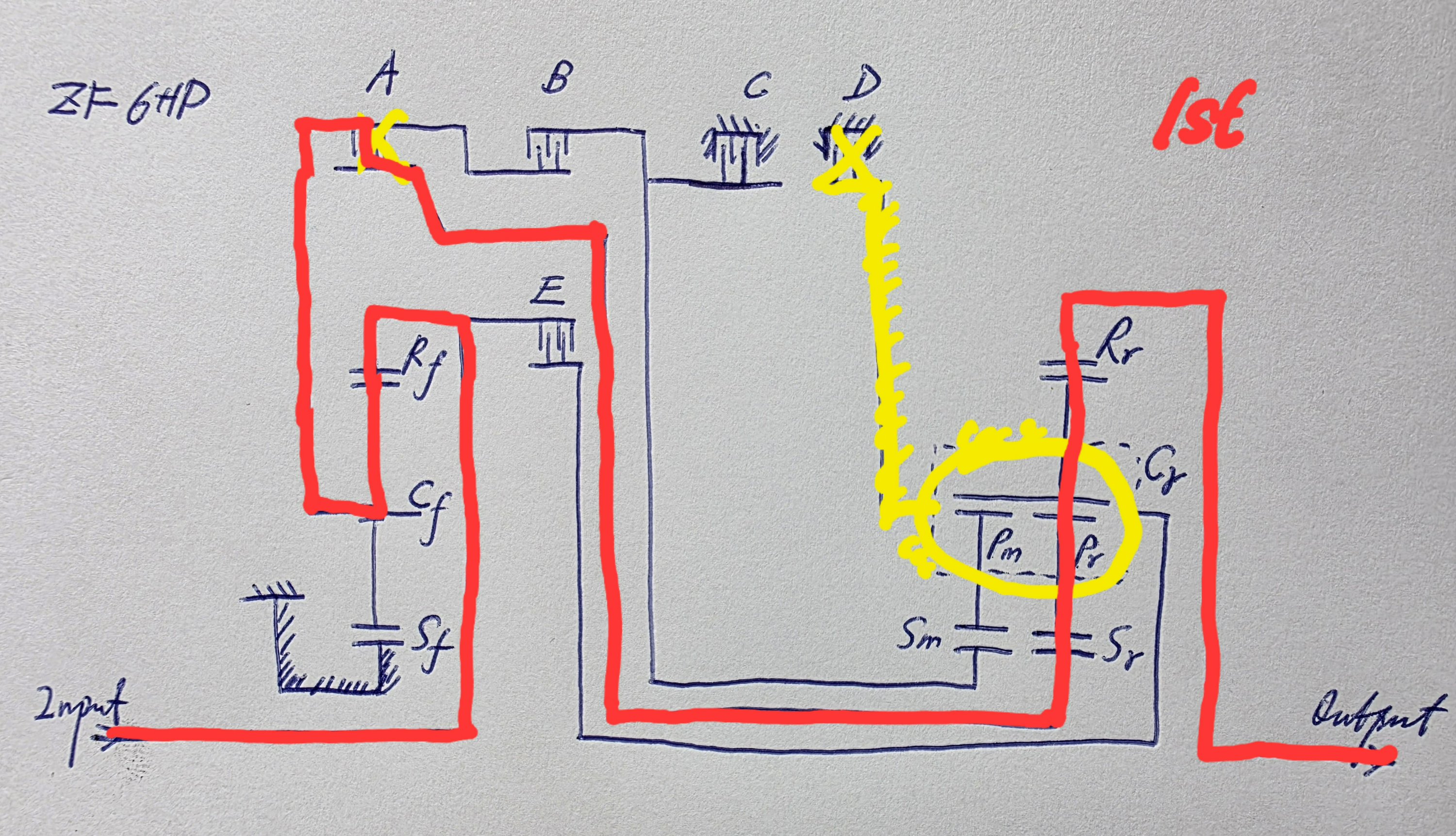

In 1st, torque passes through Rf > Cf > A > Sr > Pr > Rr. Thus, the front and rear gearsets use the two common ways of speed reduction respectively: ring gear in–carrier out, and sun gear in–ring gear out, both with the third element held still.

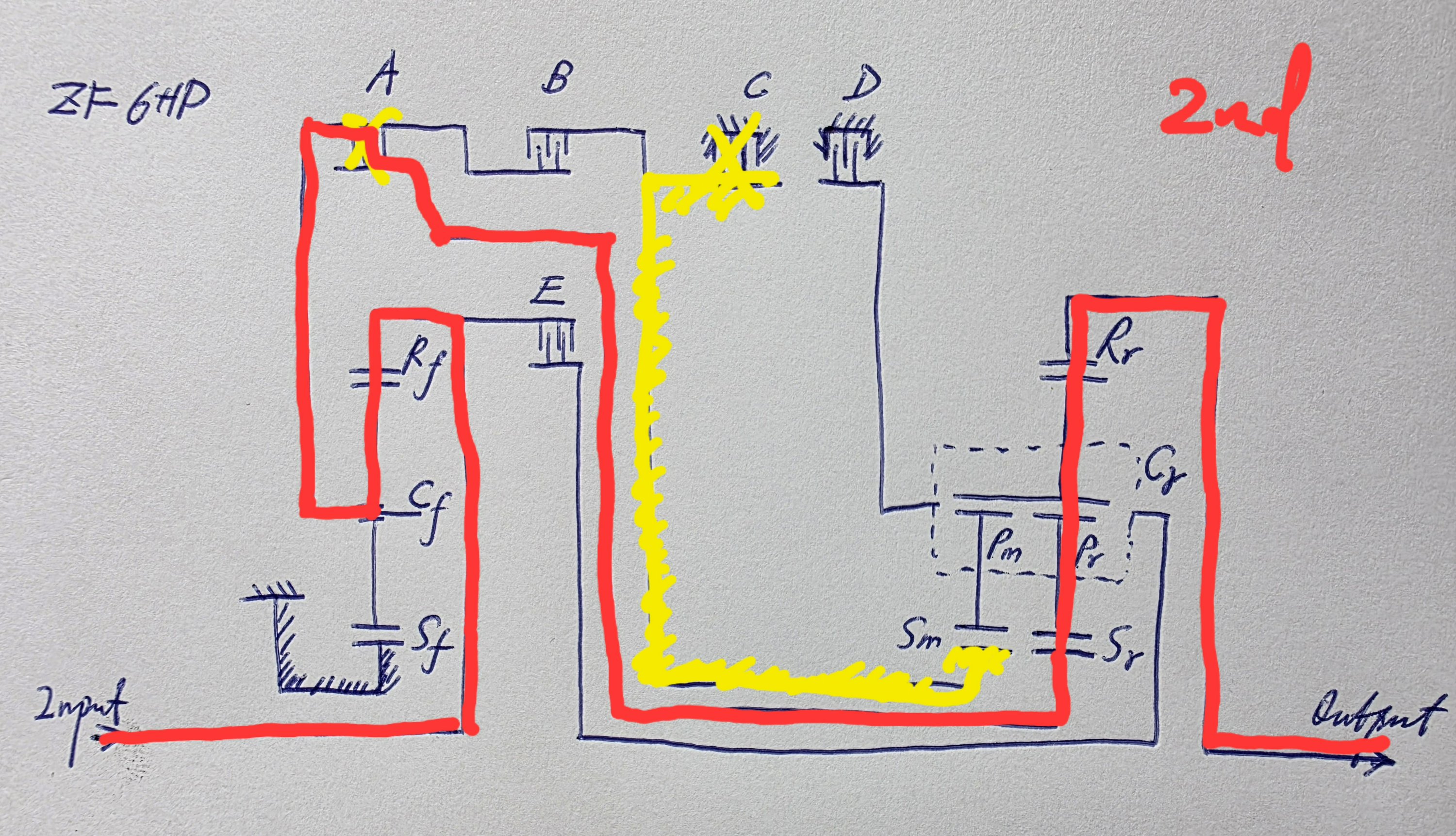

In 2nd, torque passes through Rf > Cf > A > Sr > Pr > Rr. Because Brake C holds sun gear Sm, the input of Sr forces the carrier Cr to turn.

In 3rd, torque passes through Rf > Cf > A > Sr > Cr > Rr and through Rf > Cf > B > Sm > Cr > Rr. Because the sun gears Sm and Sr have the same speed, the Ravigneaux gearset is locked as a unit. Thus, the only speed reduction comes from the front simple planetary gearset.

In 4th, torque passes through E > Cr > Pr > Rr. Rf > Cf > A > Sr also turn, but at a lower speed. This essentially creates a carrier in–ring gear out scenario, which would be overdrive, but mitigated by the turning of the sun gear.

In 5th, torque passes through E > Cr > Pr > Rr. Rf > Cf > B > Sm > Pm also turn. Crucially, as Pm meshes with Pr, the gear ratio is inverted around direct drive (1.000). This is because the two sets of sun gears and pinons in this Ravigeanux gearset have the same teeth count. Indeed, we can verify that the gear ratios of 4th and 5th multiply to 1.

In 6th, torque passes through E > Cr > Pr > Rr. Since Brake C stops Sm from turning, this is equivalent to a carrier in–ring gear out scenario.

Final Words

The ZF 6HP introduced several design philosophies to automatic transmission in passenger vehicles, chiefly internal mechatronics and TCC slip, which considerably reduce the reliability of modern transmissions. In Gears 1, 2, 3, and 6, it is using the classic Ravigneaux ratios. Gears 4 and 5 are more innovative, and we can see this exploited considerably further in the Toyota–Aisin design. Using multiple simple planetary gearsets, this design is even more broadly used in newer transmissions. Gone are the old days of holding an element stationary.