techXXX

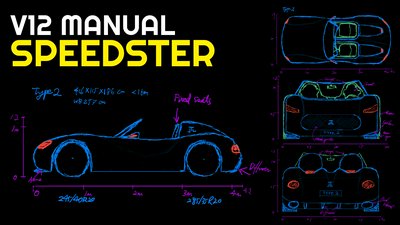

Chassis and Suspension of a V12 GT—My Car Company 09

Previously, I have covered the engine and the drivetrain of the mid-size grand tourer that I would build, Type 1. Today, let us move onto its chassis and suspension.

Published by Dr Jiulin Teng on 29 Jan 2026

Previously, I have covered the engine and the drivetrain of the mid-size grand tourer that I would build, Type 1. Today, let us move onto its chassis and suspension.

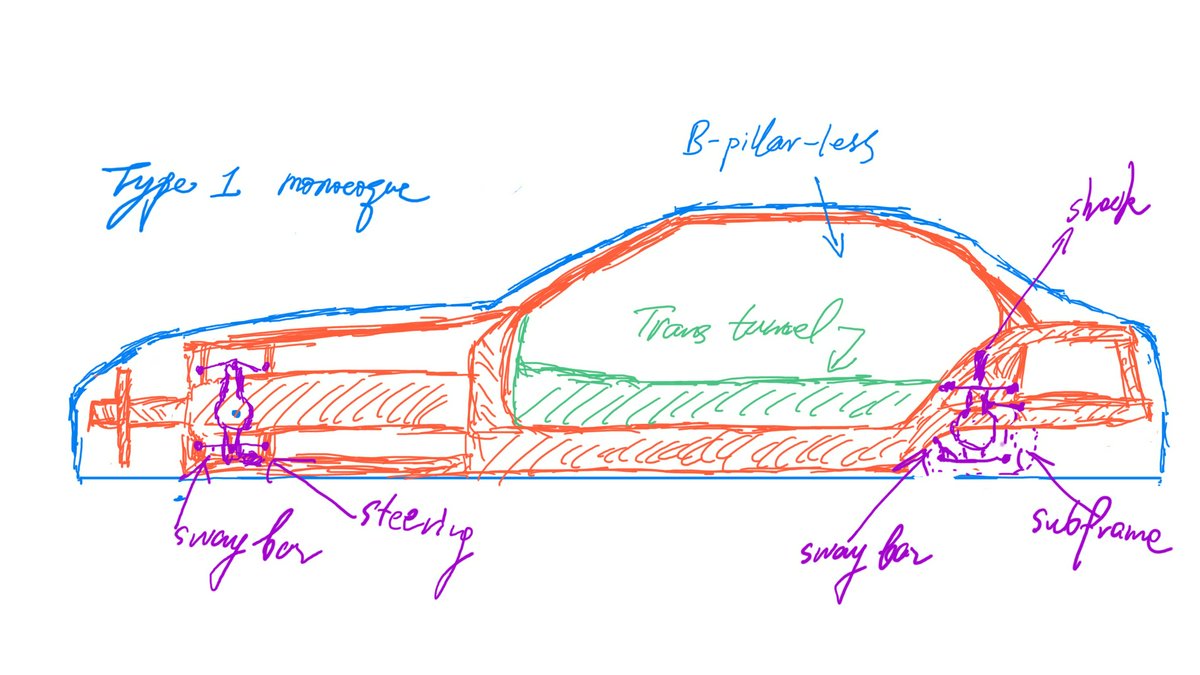

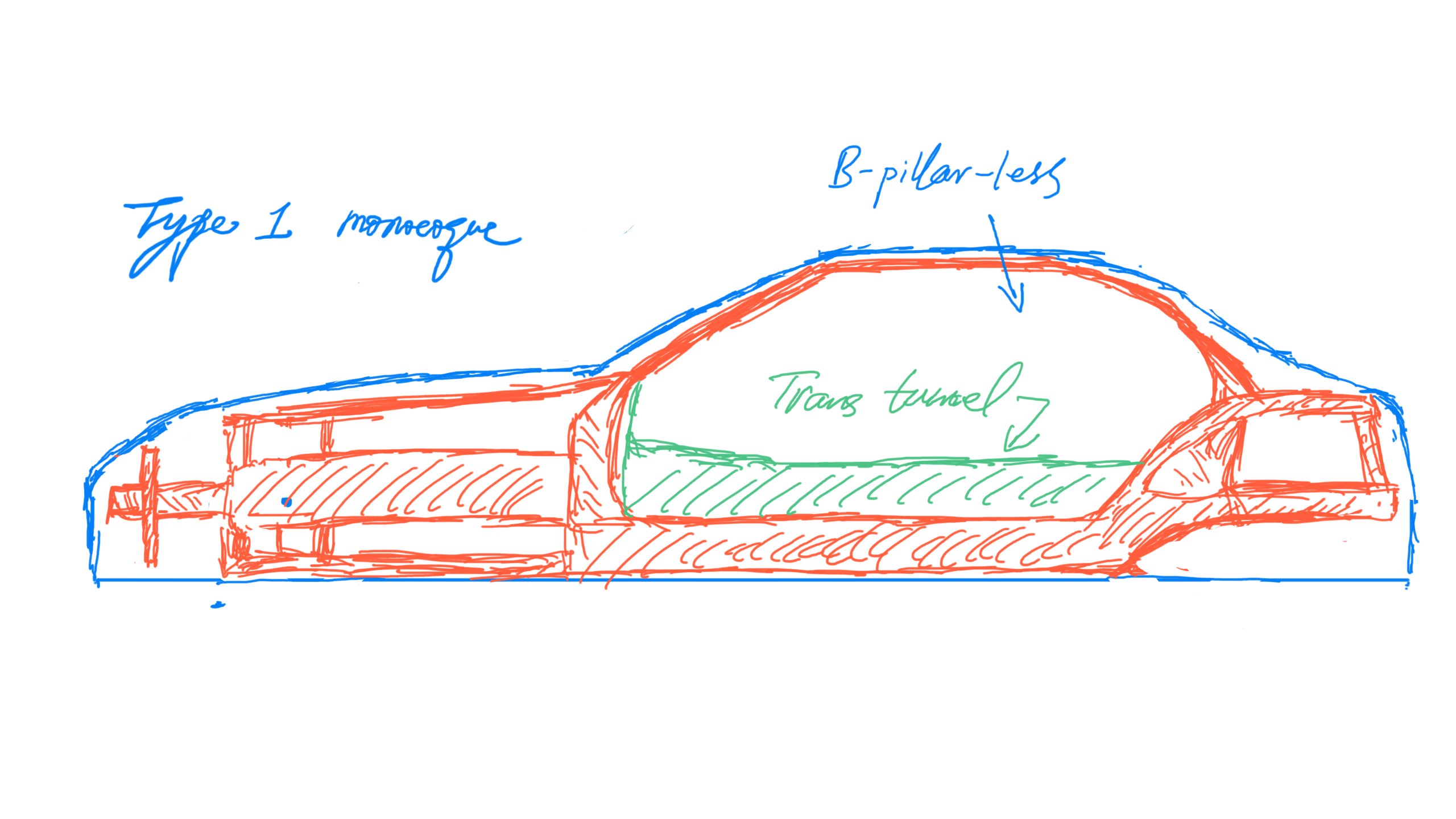

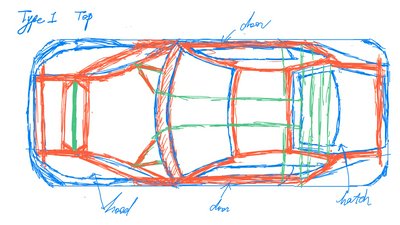

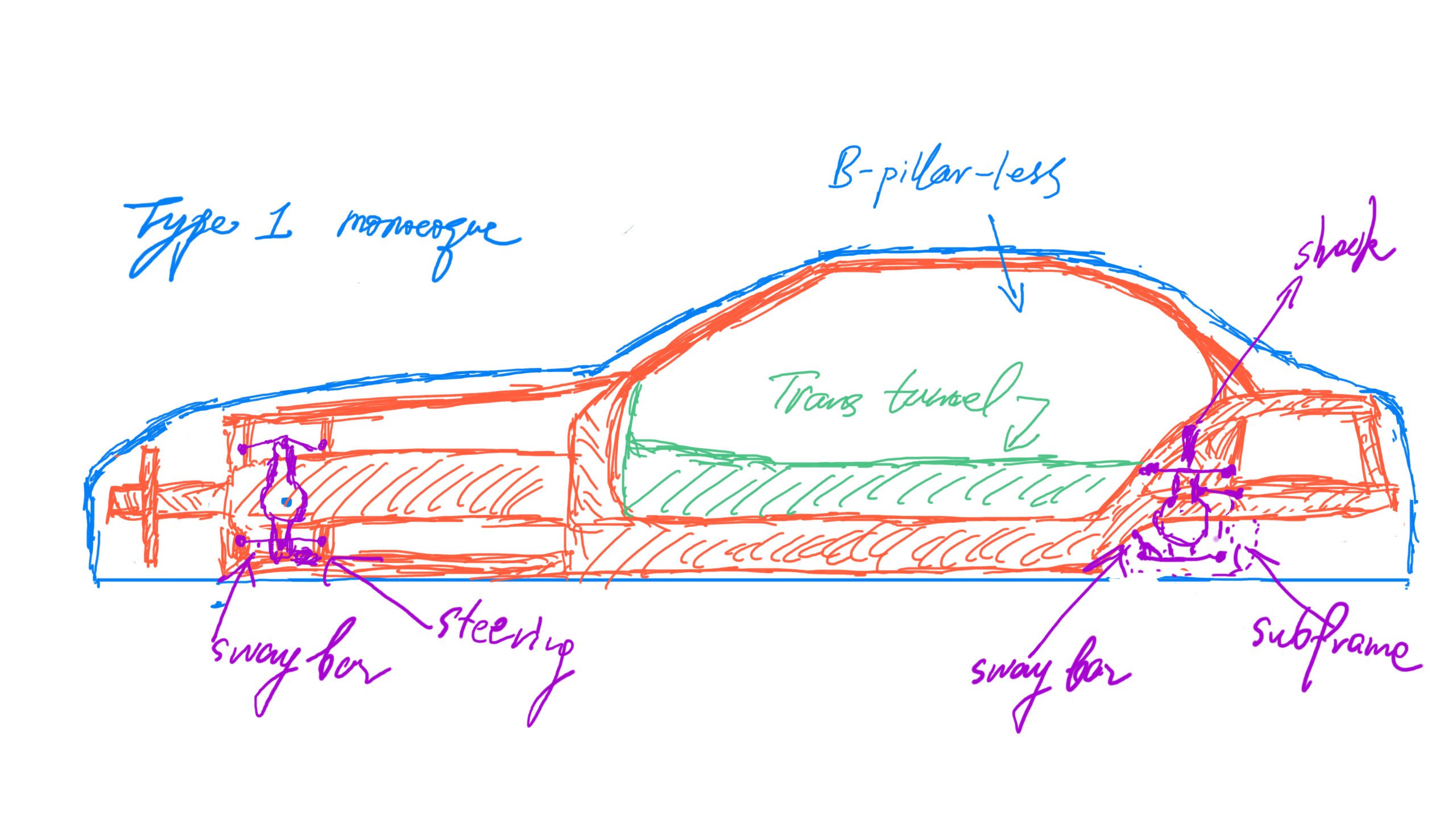

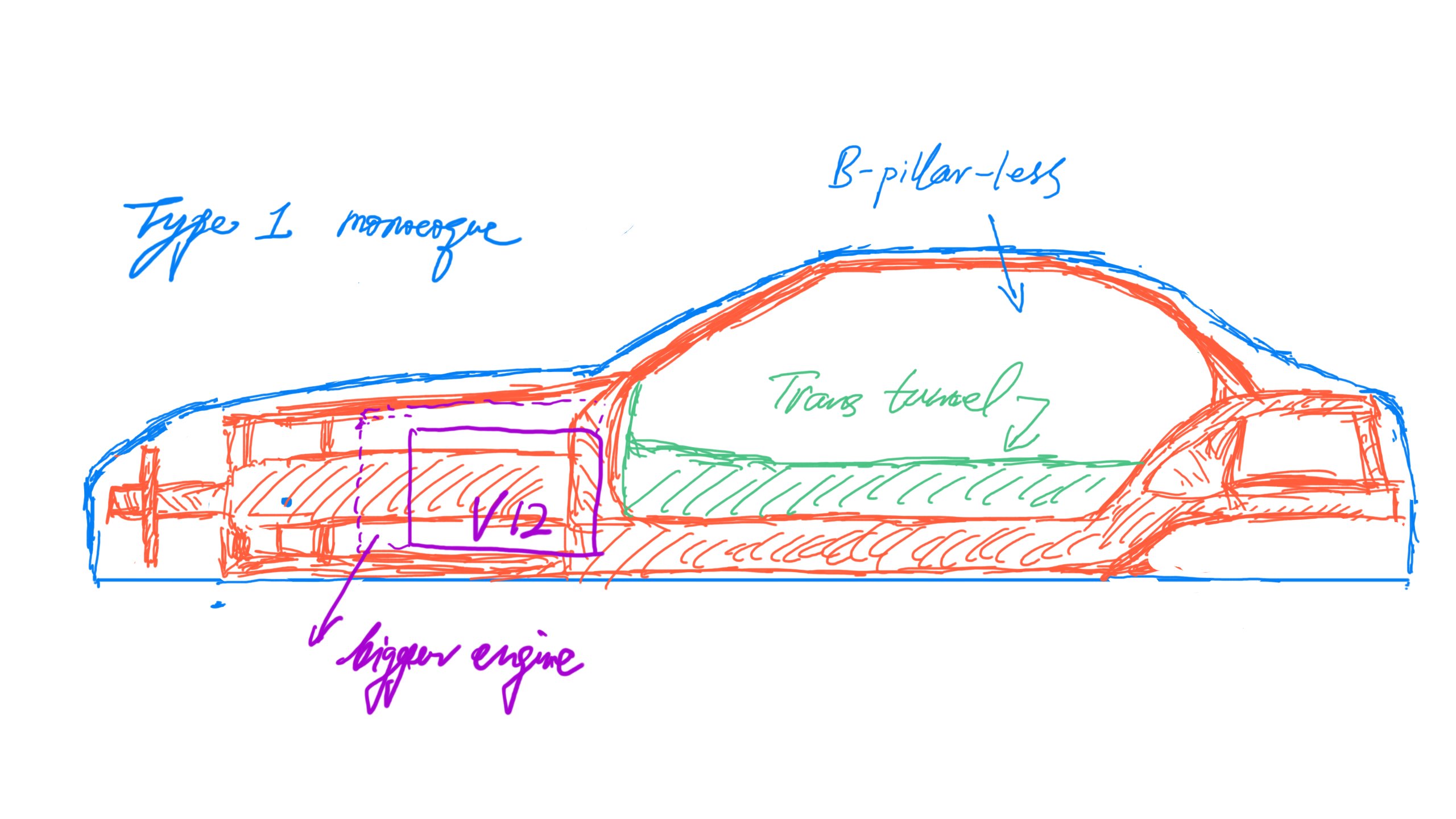

Monocoque Construction

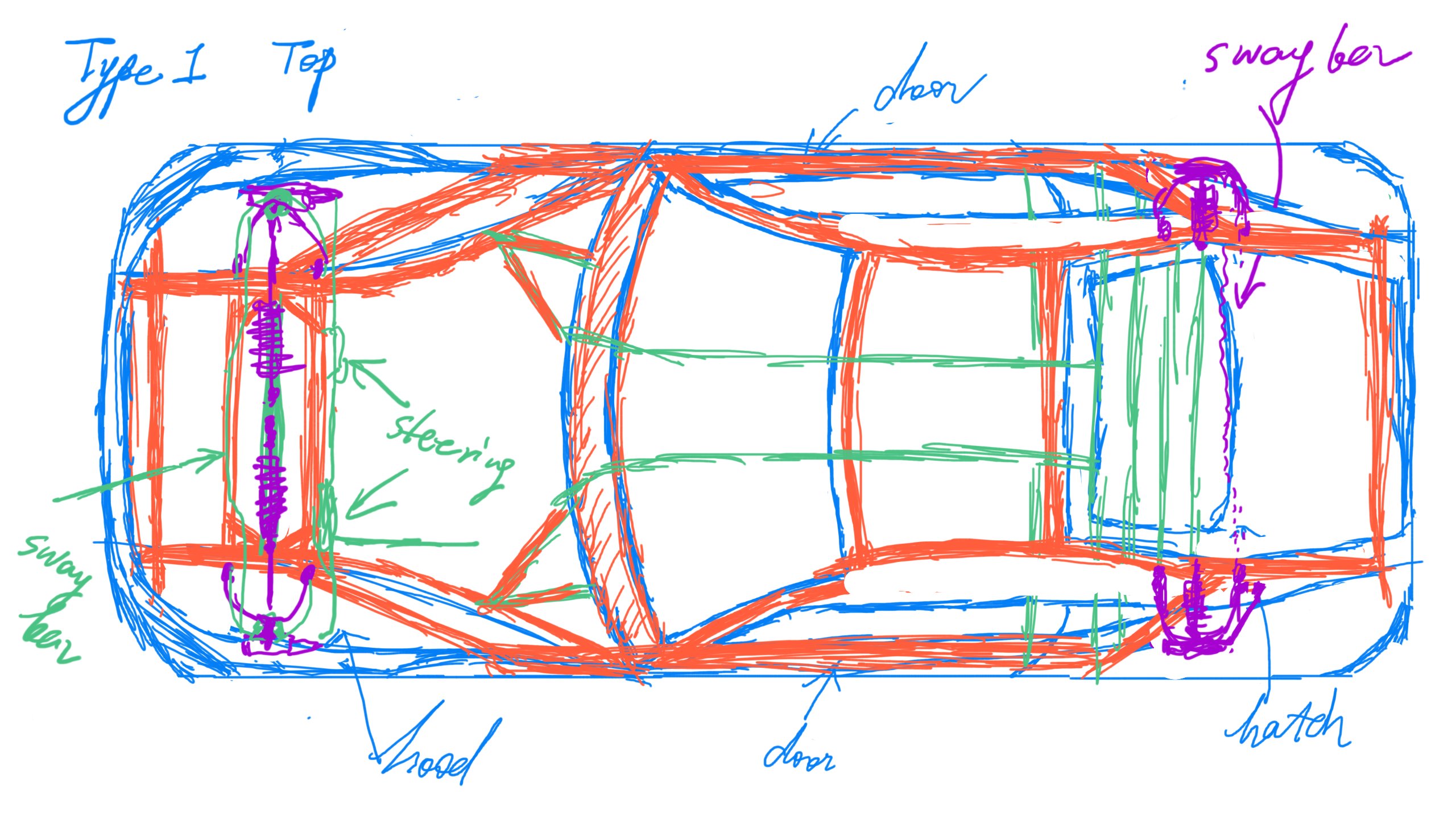

Type 1 will use, like almost all cars today, a monocoque construction. The main challenge in our case is that Type 1 has a very long yet low engine bay, that its front wheels almost reach the top, and that we also need to fit double wishbone front suspensions.

Thankfully, because our engine is completely behind the front wheels, we have an easier time optimizing the chassis. In our case, the front suspension loads are not competing with engine packaging, and we can build a closed suspension box with the front bulkhead. Examples of cars with this chassis construction include Ferrari F12 and 812, AMG GT, and Toyota GR GT. An older, more compliant design that follow a similar philosophy is the Maserati Quattroporte V.

Double Wishbone + Pushrod Front Suspension

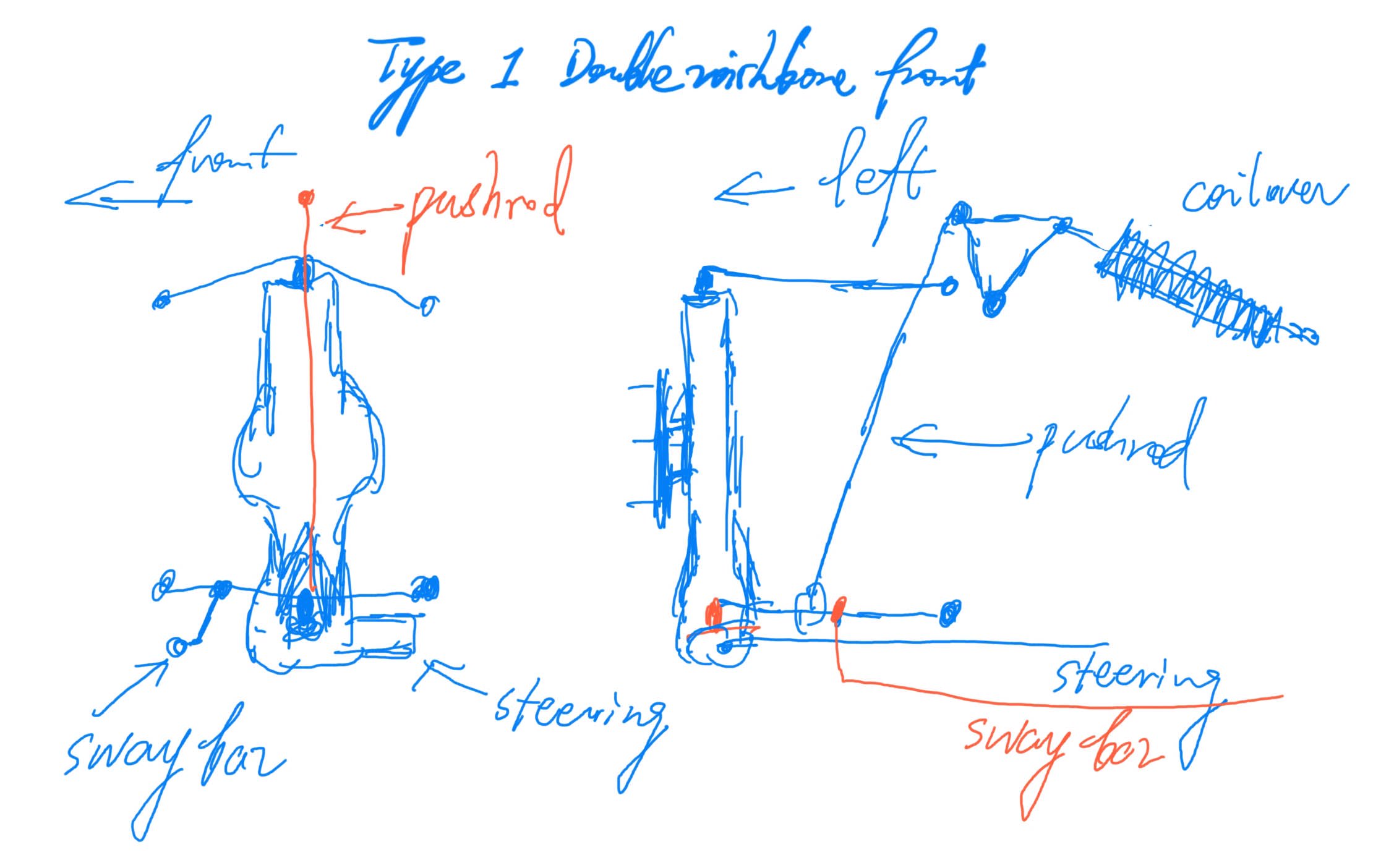

Ideally, a double wishbone setup favors the upper wishbone above the tire and a vertical shock installation. We cannot do that. Instead, the upper wishbone needs to slope downward from the steering knuckle, which is completely tucked below the top of the front wheels. Its inner pivots sit on the front bulkhead.

Unlike the aforementioned exotics, ironically, Type 1 would have inboard pushrod front suspensions for two reasons: One, our compact engine leaves a lot of room under the hood, which makes pushrod suspension feasible. Two, as a design choice, we have a very low hood line combined with large wheels, which requires us to use an unconventional setup. For enthusiasts, this adds much more adjustability for the suspension geometry. It will also perform better than a tightly-packaged, highly-inclined shock absorber.

Normally, we associate push and pull rod suspensions with race cars and their lack of refinement. However, refinement is only deprioritized in the racing context. We can add refinement back by using bushings instead of pure spherical joints, thick cast rockers mounted vertically, and refined shock absorbers. Designed right, this can offer the best of both worlds without adding too much to the cost.

Obviously, we do not use electronic nonsense here. Instead, we will offer upgrade options for the owners. Through our open-source program, we hope there will also be many aftermarket suppliers doing the same. Indeed, there will be enough room left for a larger engine that can be released later as a less high-strung option with more low-end torque.

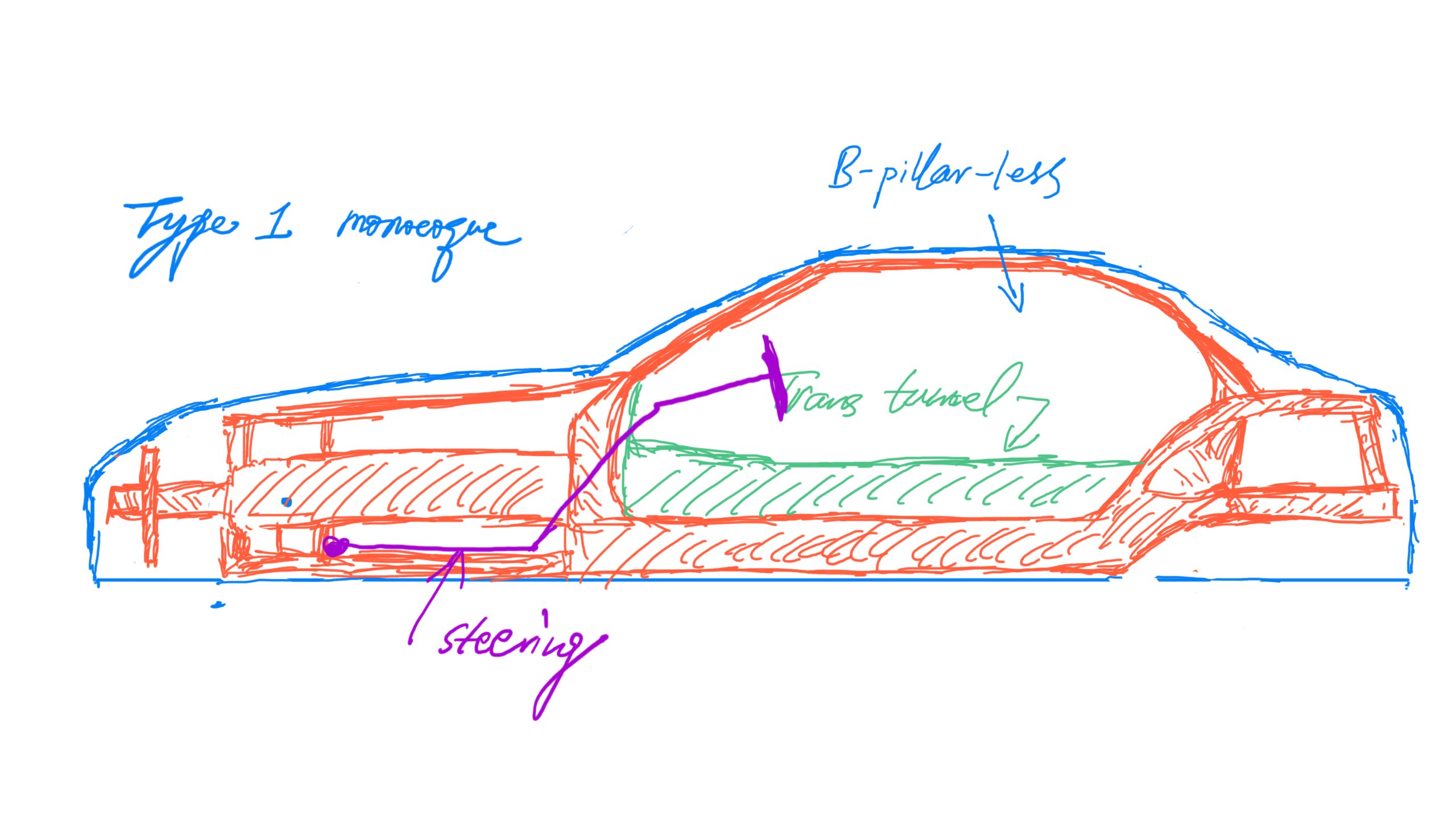

Electric Power Steering

While we want to minimize the use of electronics in Type 1, it still makes sense to use electric power steering. This technology is already mature, and it is lighter, more compact, and indeed simpler than a hydraulic power steering setup. We just need to make sure that it is well-tuned.

Another aspect about steering is the turning radius. At 309cm, our reasonably-sized GT has a very long wheelbase. This is great for stability but sacrifices agility. We have to accept this. While a steering rack with more travel could alleviate the issue, it would hurt the suspension setup and steering feel. Thankfully, Type 1 has a manual transmission, which tolerates rapid shifts between reverse and 1st much better than any type of automatics.

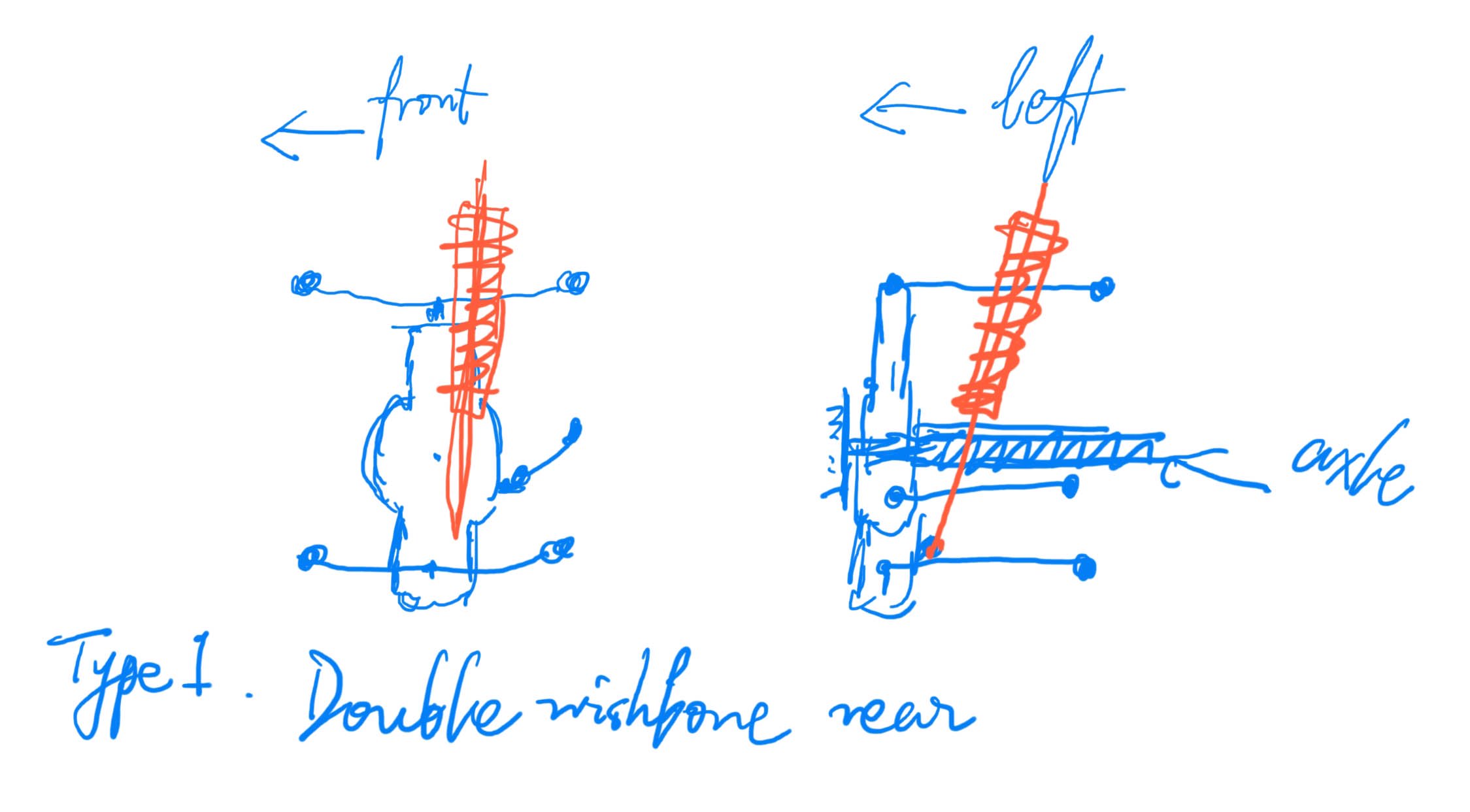

Double Wishbone + Coilover Rear Suspension

Usually, multi-link is used in the rear of a high-end vehicle thanks to its ability to maintain suspension geometry better. However, it is slightly less precise than double wishbone, and an owner trying to tune the suspension can easily ruin the car’s handling. Hence, Type 1 will use double wishbone rear suspensions in conjunction with coilovers.

Thanks to not using a transaxle setup, we can adopt longer, flatter control arms that maintain suspension geometry through travel better. However, we should balance this with unsprung weight reduction. The choice of coilover brings two advantages: One, by having the spring over the shock, a lighter, more compact spring can be used to achieve the same suspension stiffness. Two, by not separating the spring and the shock absorber, a coilover is slimmer.

Brakes

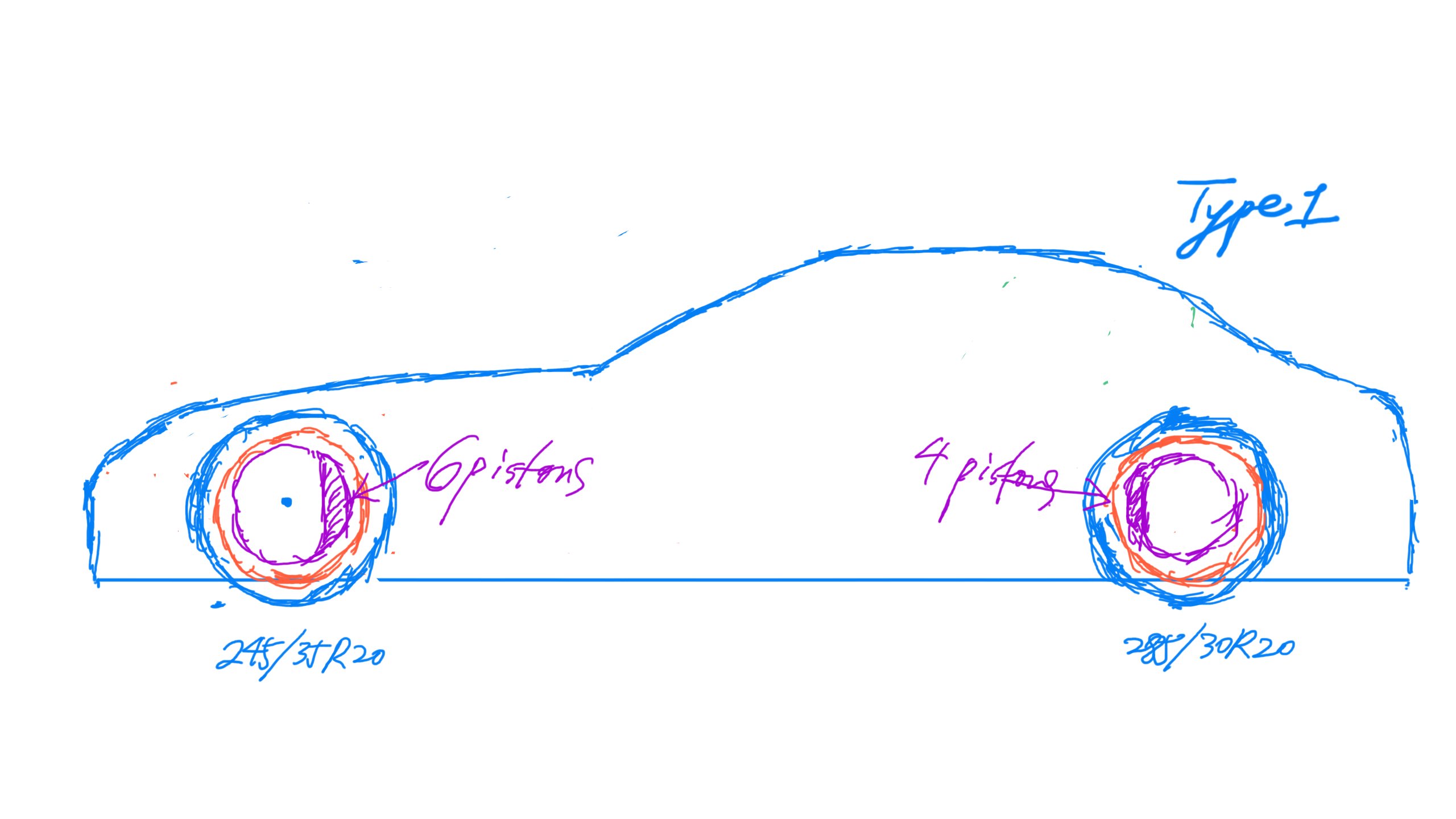

Type 1 will use classic monobloc aluminum brake calipers with 6 pistons at the front and 4 pistons at the rear. The standard option will be steel rotors, though we may offer carbon ceramic options later to use with the same calipers. The exact sizes will need to be tested to balance braking performance, unsprung weight, and styling.

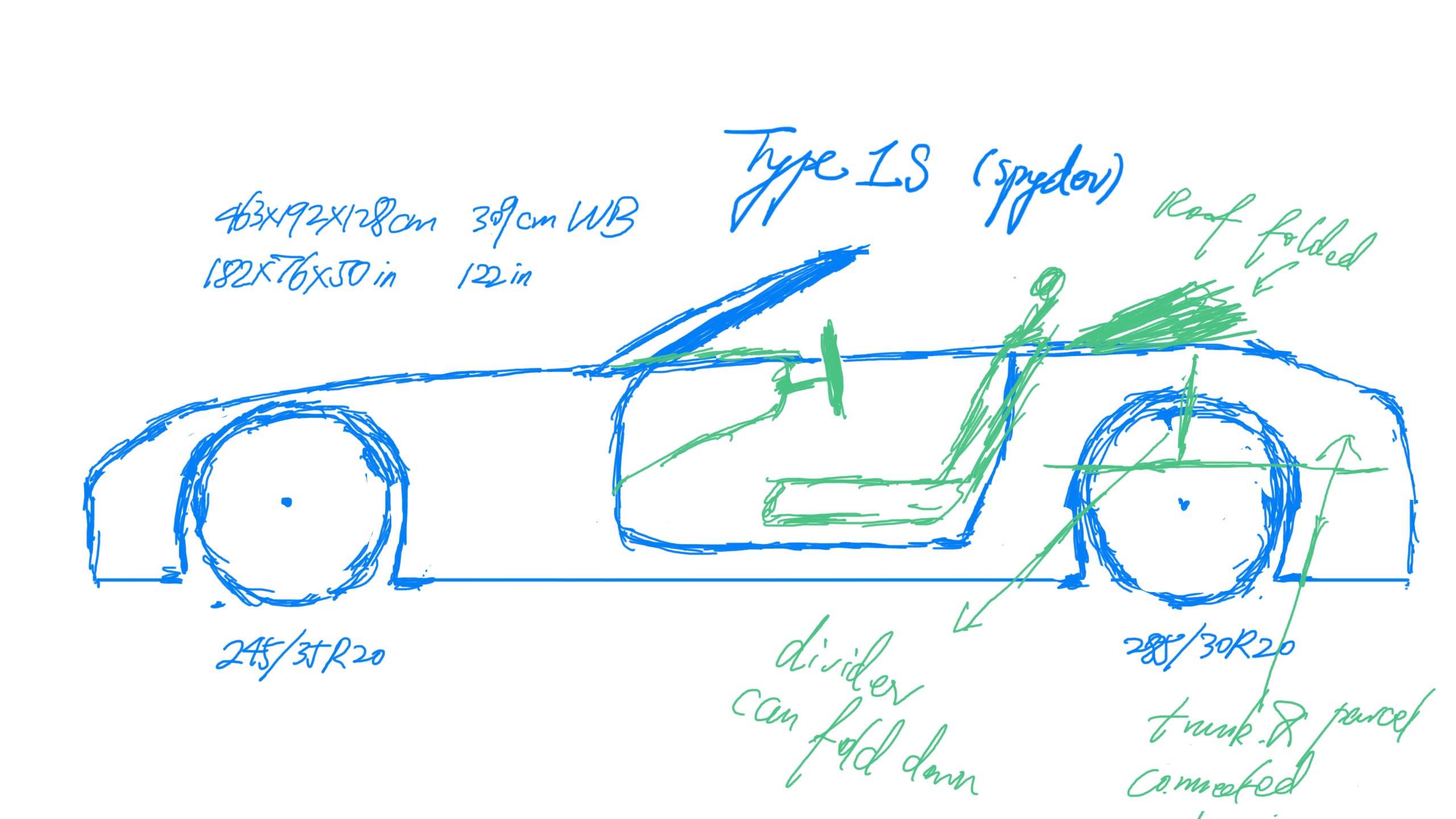

Convertible Readiness

A key consideration in designing the chassis and suspension for Type 1 is the possibility to introduce a convertible version. For the coupe version, we skip some reinforcements down low and rely on the roof to provide more torsional rigidity.

Next Up

In the next post, I will discuss the exterior design of Type 1.