techXXX

Designing the Engine Block for a 3L NA 11.5k-rpm V12—If I Had a Car Company 03

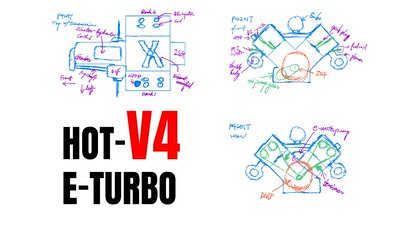

Previously, I laid out the specifications of the PC301, 3L naturally-aspirated V12 engine that I would build if I had a car company. Today, let us delve into the details of the engine block.

Previously, I laid out the specifications of the PC301, 3L naturally-aspirated V12 engine that I would build if I had a car company. Today, let us delve into the details of the engine block, specifically:

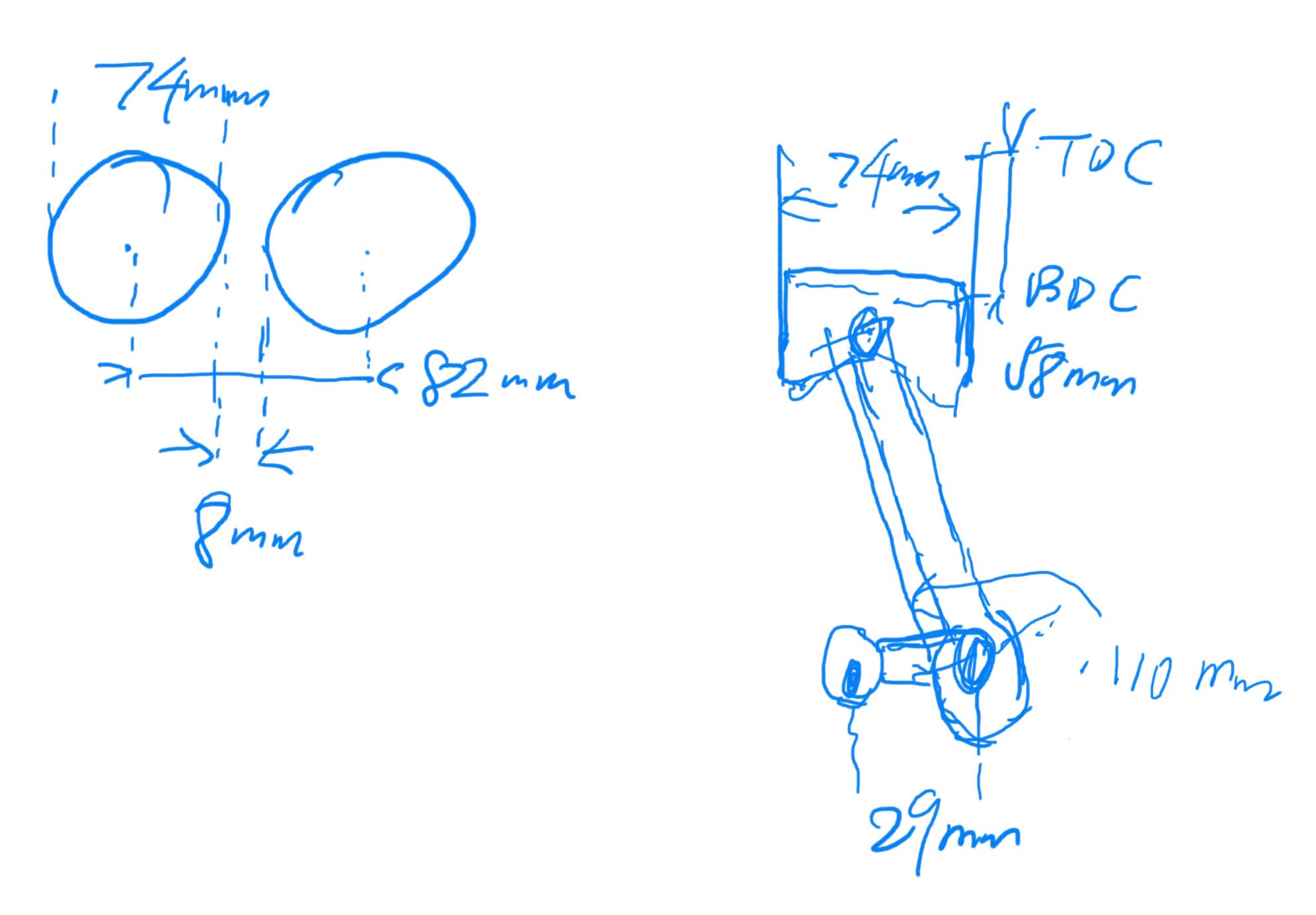

- Bore x stroke: 74mm x 58mm

- Cylinder spacing: 82mm

- Rod length: 110mm => 1.9 rod ratio

- Bank angle: 60°

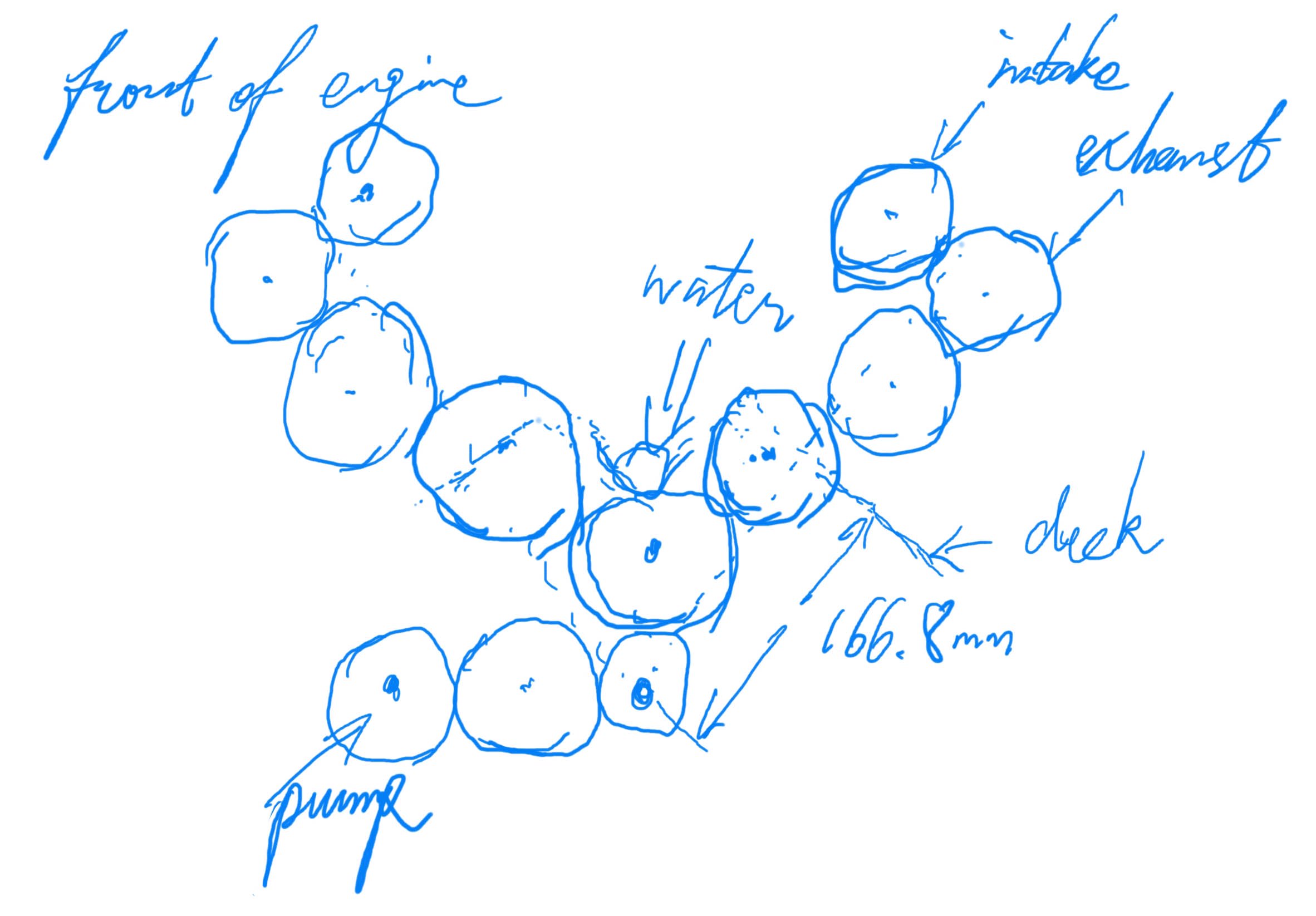

- Water jacket: Closed deck

- Timing: Straight-cut gears

- Block material: Hypereutectic aluminum block + Nikasil coating

Bore and Stroke

A higher bore–stroke ratio brings a few advantages for power: It allows for relatively large valves in relation to the displacement, which means better airflow and higher RPM ceiling. A shorter stroke also lowers the piston speed and peak piston acceleration at a given RPM, where the Mean Piston Speed (MPS) equals

MPS = 2 x stroke x rpm/60

while the peak piston acceleration correlates with stroke x rpm2.

Nevertheless, a lower bore–stroke ratio entails lower throttling loss, which is important for thermal efficiency. This is because intake velocity is made higher at part throttle conditions. Similarly, a lower bore–stroke ratio means higher peak torque at lower RPMs.

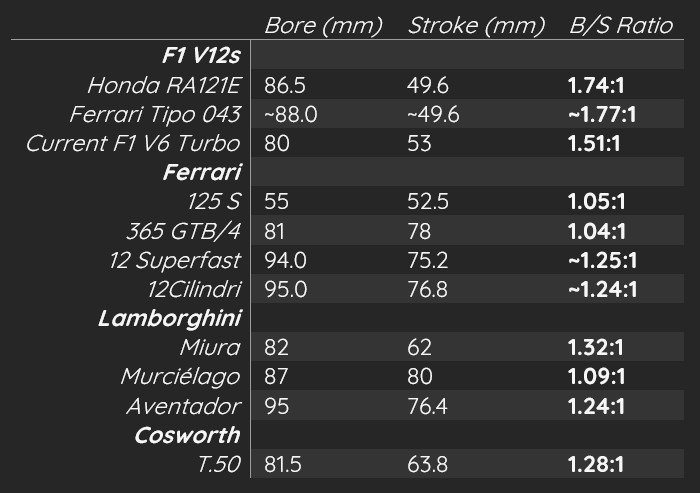

For an engine targeting the working enthusiasts, an oversquare setup that is not too extreme can balance top-end performance and daily drivability. This is why I believe 74mm bore, 58mm stroke, and a 1.28:1 B/S ratio is spot on. A racing engine would be more oversquare, while a V12 designed for luxury cars should be less so.

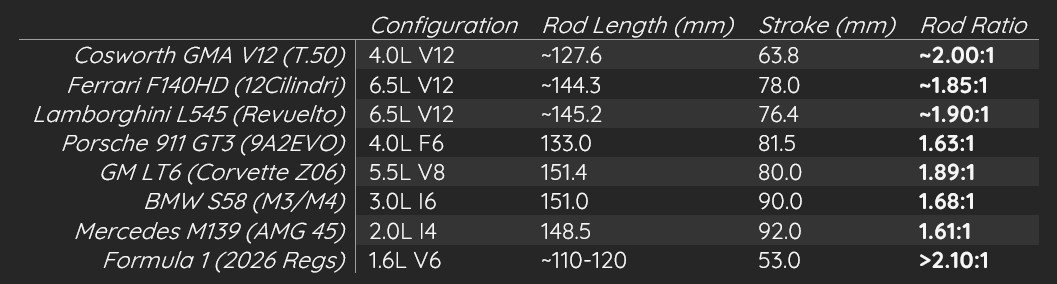

In comparison, according to the internet:

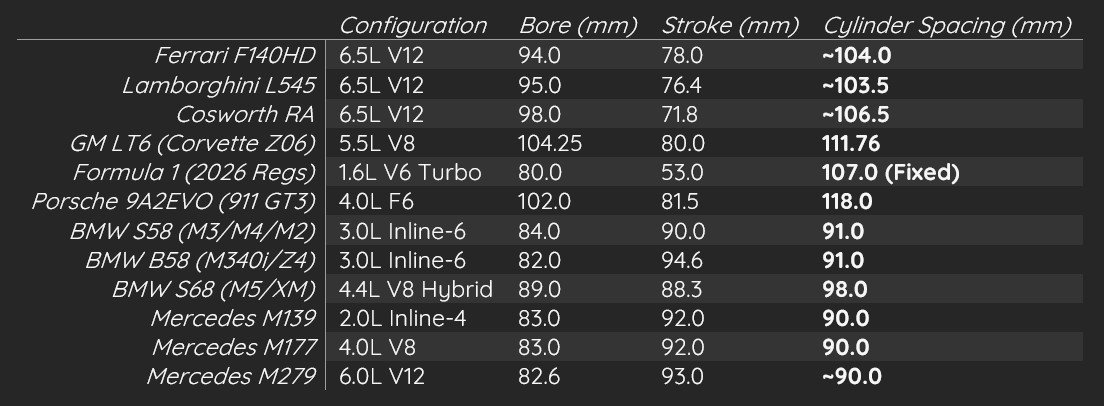

Cylinder Spacing

Several factors are at play when choosing the cylinder spacing. Cylinder stability and engine block durability favor a larger spacing, while packaging and weight lean the other way. We also need to leave enough width for the rod and main bearings. This is important in a V engine, as two conrods need to ride side-by-side comfortably. It is more acute in our case, because our small displacement engine, though oversquare, has a bore of just 74mm.

Since we expect our customers to use our cars daily, and they are not the ultra-wealthy, reliability is very important. For this reason, I believe an 82mm spacing is a good idea.

In comparison, according to the internet:

Rod Ratio

Choosing the rod ratio, which is rod length divided by stroke, is to balance high-RPM stability and longevity versus low-end torque and volumetric efficiency. This is because a shorter rod accelerates the piston away from TDC faster but increases side loading. A longer rod dwells at TDC longer and allows for more complete combustion before expansion begins; this also reduces peak piston acceleration, which happens at TDC.

Since we have a small displacement V12, we need it to rev high to make more power. We also need to favor durability. However, deck height, which is the distance from the crank centerline to the top of the block, and piston compression height are two constraints. We are building a good engine for daily drivers, not a racing engine. Therefore, I think a 110mm rod length, which results in a 1.9:1 rod ratio is a good idea.

In comparison, according to the internet:

Straight-Cut Timing Gears

The choice of timing gears is borne out of necessity and the desire to make the engine durable. Timing chains, which are more common in road-going engines, cannot reliably sustain 10k+ RPM operations. Chains would start whipping due to centrifugal force in what is called “chordal action”. The load on the tensioners would explode. According to the AI, chains may also enter resonant frequency at around 12k RPM, which, if happens, can shatter the chain.

High-revving engines usually use gear drives or high-performance belts. The latter because they are lighter and can dampen harmonics. Gear drive can also take the form of bevel gears combined with a vertical drive shaft, as found in aircraft engines. However, for daily drivers, straight-cut gears are the easiest to implement and maintenance-free. They also come with a characteristic whine that enthusiasts will surely love.

We need to keep in mind, however, that gears come with trade-offs: They incur higher parasitic loss, and the rigid connection can transmit crankshaft harmonics to the valvetrain. Fortunately, we have a V12 with the best harmonic characteristics.

Going back to my comment in Episode 2 about the 4.0L V12 with 9k RPM redline, that engine could potentially use conventional chains or belts.

Hypereutectic Aluminum Block + Nikasil Coating

Traditionally, wet liners made of iron or steel are used for durable engines. They offer excellent bore stability, serviceability, and easier piston pairing. However, they are heavy, create thermal bottleneck, and increase friction. This is where a hypereutectic block with Nikasil coating is superior:

It offers excellent heat transfer, mass reduction, and lower friction from the Nikasil coating combined with the stiffness of a hypereutectic aluminum block. Since Nikasil allows narrower rings and lower ring tension, there is less oil film shear, too. The engine not only is more efficient but can safely operate at a higher RPM. Additionally, a hypereutectic block is stiffer and offer lower thermal expansion, which is another benefit.

A modern alternative is plasma spray, but that carries similar trade-offs of liners without the benefits.

I should note that Nikasil is not Alusil, which would be just the bare hypereutectic block without Nikasil coating, or Lokasil, which is a cheaper process to build blocks with worse trade-offs.

Final Words

Besides the metrics discussed above, 60° bank angle and closed-deck water jacket need no explanation for this application. In the next post / episode, I will cover the rotating assembly.