techXXX

Designing the Rotating Assembly for a 3L NA 11.5k-rpm V12—If I Had a Car Company 04

Today, let us move on to the rotating assembly of the 3L naturally-aspirated V12 engine that I would build if I had a car company.

In the last post, I explained the reasoning behind the key metrics of the engine block of the 3L naturally-aspirated V12 engine that I would build if I had a car company. Today, let us move on to the rotating assembly, specifically:

- Piston: Forged 4032 aluminum pistons

- Piston pins: 9310 steel, 21mm OD, 16mm ID, DLC coating, Fully floating

- Small-end bearing: Plain bronze

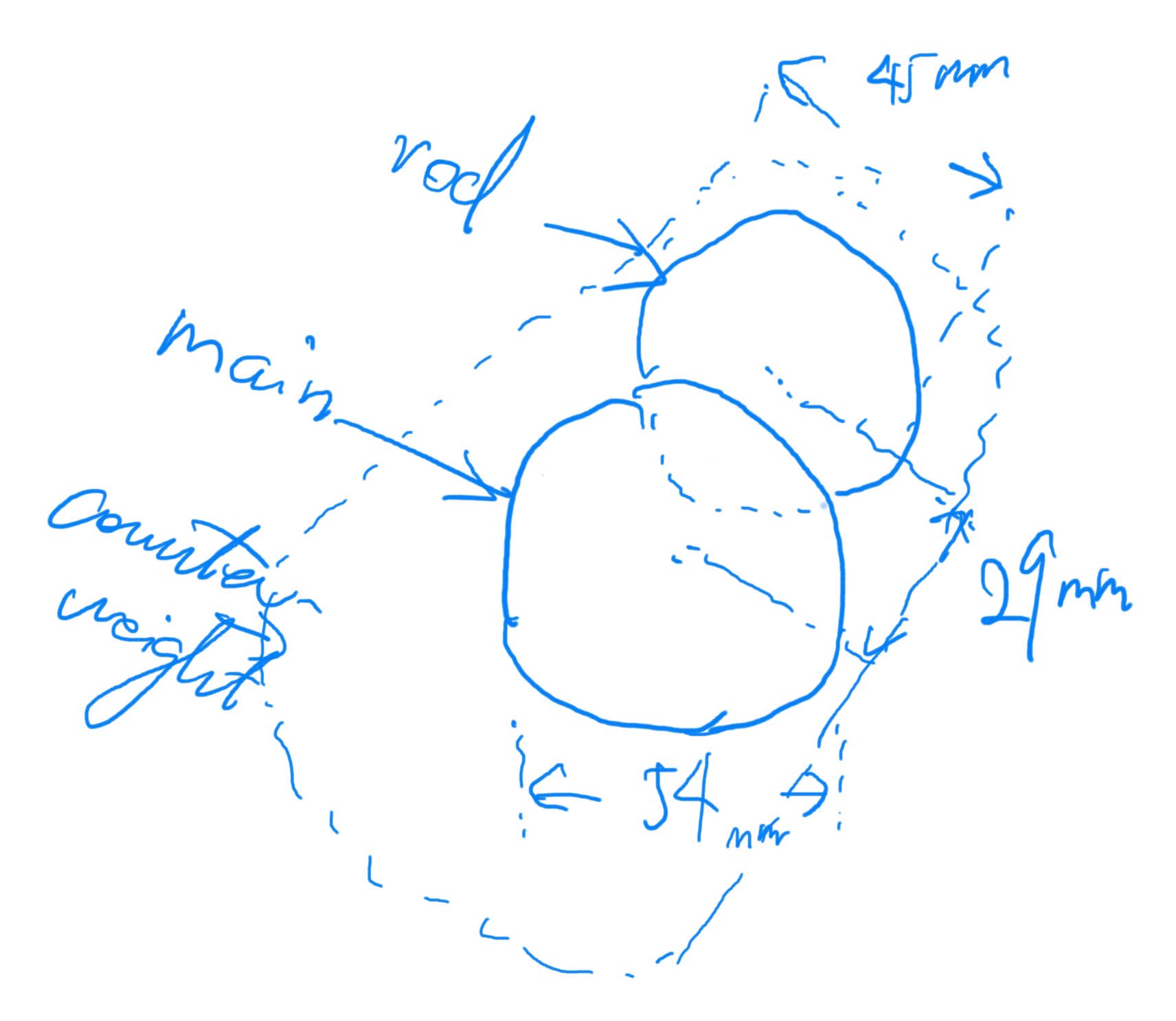

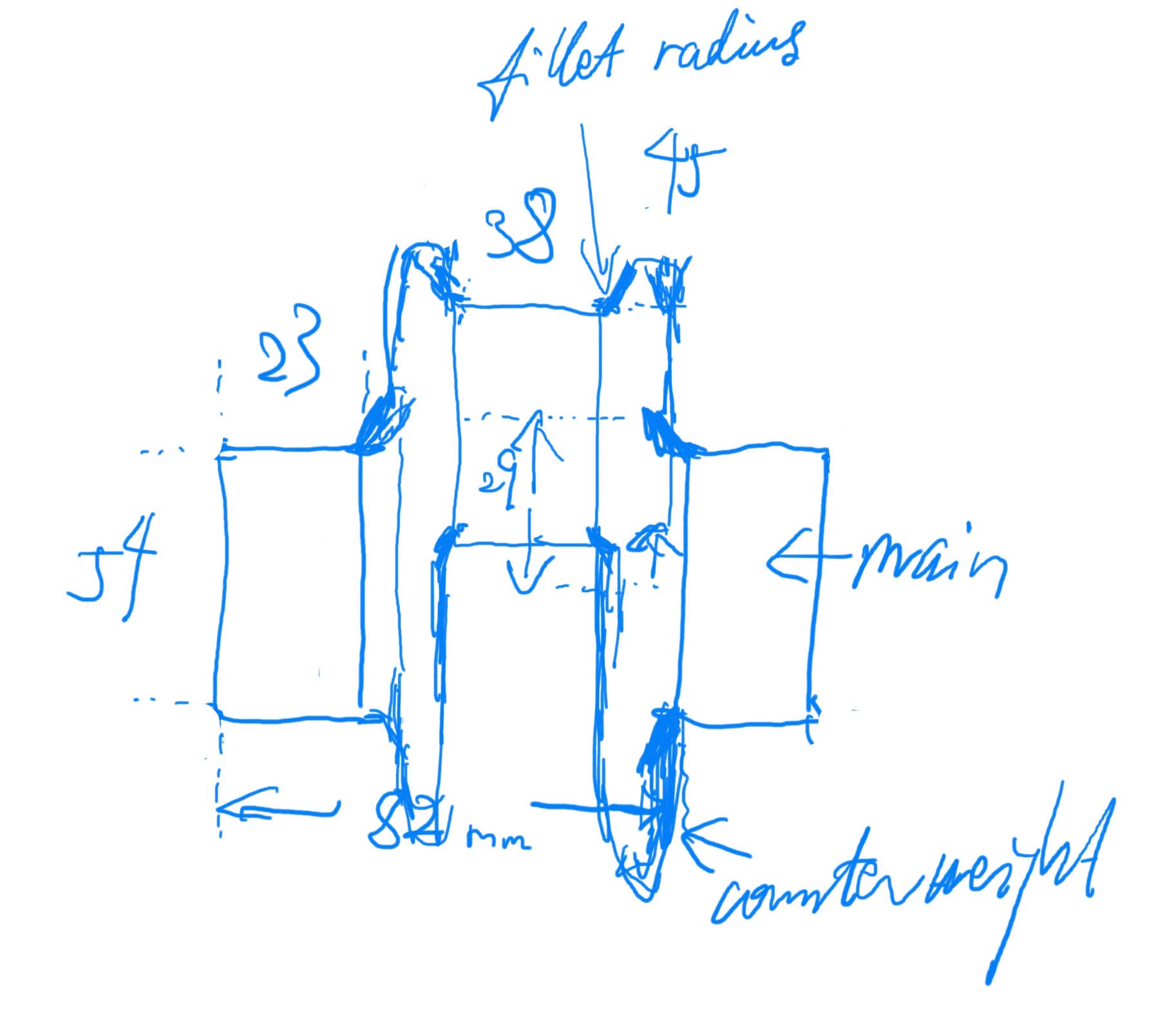

- Crankpin journal: 45mm diameter, 38mm width

- Main journal: 54mm diameter, 23mm width

- Bearing clearance: .038mm

- Bearing material: Tri-metal

- Main bearing fixture: Bedplate

- Crankshaft: 4340 forged steel

- Conrod: 4340 forged steel

- Dry-sump oil pump: 50% crank speed, 5 stages (1 pressure + 3 pan scavenge + 1 valley scavenge), Pre-oiling before engine start

- Oil viscosity: 5W40 or 5W30

- Flywheel: Single-mass, Billet steel *size, weight need engineering

- Fastening: Waisted studs, ARP bolts

Bearing Sizing

Three competing factors drive bearing diameter: Surface speed favors a smaller diameter, as the loss from oil shear explodes with larger ones. Unit loading favors a larger diameter, which helps with oil film strength. So does crank stiffness. However, for a small-displacement, naturally-aspirated, high-revving engine, surface speed is the first limiting factor.

Surface speed v = π x D x RPM/60. At 12k RPM, just above the redline, a 45mm crankpin would yield a surface speed of 28.26m/s. This is rather sensible and should be a good balance for durability.

Main bearings do less work than rod bearings. The decision becomes a trade between stiffness and loss. For a small-displacement, road-going V12, a 54mm main bearing diameter is a good balance.

With an 82mm cylinder spacing, the choice of bearing width is limited. To sustain oil film strength, it should not go under 17mm for the big end or 22mm for the main. Therefore, the choice of 18mm for rod bearing width and 23mm for main bearing width is borne out of necessity, since we also need to account for fillet radius, cheek thickness, and thrust oil clearance.

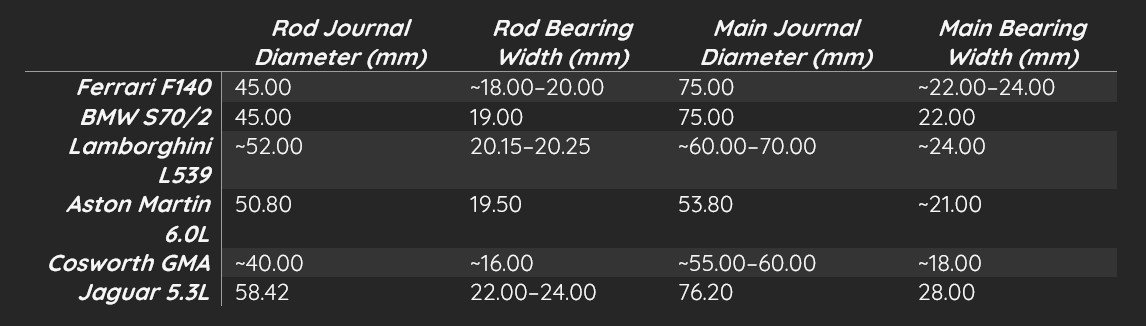

In comparison, according to the internet:

Bearing Clearance

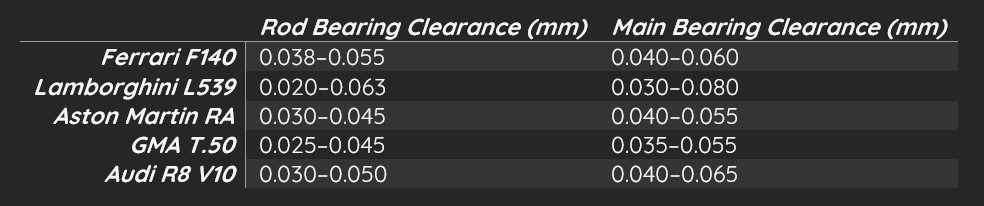

A rule of thumb for bearing clearance is one thousandth of the journal diameter. However, ours is a high-revving engine that must run tighter clearances. This is because at high rpm oil escapes more quickly. A looser clearance risks oil wedge collapse, in which case we leave the hydrodynamic phase of lubrication, resulting in excessive wear. Additionally, large clearance would necessitate much higher oil flow rate, which increases shear heating and thereby bearing temperature, again leading to bearing failures.

Hence, for something that can rev to 12k RPM, we should aim for 0.6 to 0.8 thousandth of the journal diameter. At the same time, since our car is designed for street use and will mostly run under 10k RPM, I believe choosing the upper end of this range is sensible. This is how I arrived at 0.038mm for both rod and main bearing clearances.

In comparison, according to the internet:

Bearing Material

The bearing in our V12 sees very high surface speed and cyclic loading but moderate combustion load, and it must survive tight clearances and be durable. Tri-metal bearing is great for this application. The steel backing provides stiffness that keeps the bearing round at high RPM, which is essential for clearance control. The copper-lead intermediate layer has very high fatigue strength and excellent thermal conductivity, which is great for high RPM cyclic loading. The soft overlay on top is more forgiving with small debris and prevents seizure.

Aluminium-tin bearings cannot offer the same characteristics and are more suitable for low-RPM engines with larger bearings and looser clearances. As I repeated time and again before, a 4L V12 with 9k RPM redline could potentially make do with it.

Forged Internals

For an engine that goes to 12k RPM, we cannot use cast pistons. This is particularly because our small displacement engine with Nikasil coating needs pistons with thin rings and minimal crevice volume, the latter being the space between the first compression ring and the piston crown. Cast pistons are more prone to cracking at high RPM.

Forged 4032 piston expands slightly more than cast pistons but does so more uniformly; it also has minimal distortion. These are important for Nikasil.

Forged 2618 piston has more expansion and is less compatible with Nikasil. Its strength is only meaningful for forced induction.

Again, a 4L 9k RPM V12 can do with cast pistons, which are more economical.

Needless to say, the crankshaft and conrods should be made of 4340 forged steel. This balances strength with cost. Titanium rod or billet steel crank is unnecessary for our output level.

Dry Sump Oiling

With our combination of high RPM and tight clearances, dry sump lubrication is all but necessary. At high RPMs, a rotating assembly can aerate engine oil. Dry sump systems use baffles and separators in the external tanks to remove air bubble and foam before recirculating oil to the bearings. They also allow for precise control of oil pressure, which is essential for working with tight clearances.

Additionally, by reducing windage, which is the parasitic drag when the rotating assembly spins through a cloud of oil, we improve the overall efficiency of the engine. By having a vacuum in the crankcase, which improves piston ring sealing, we can use low tension rings that further reduce internal friction and are more compatible with Nikasil.

Lastly, our already small engine gets to be mounted even lower in the engine bay, resulting in better handling characteristics. We can also pre-pressurize the oiling system before engine start using an external oil pump. This dramatically reduces engine wear.

For our setup, a pump with five stages, one pressure stage, three scavenge stages in the pan, and one scavenge stage in the valley is a great choice. We should use the external gear type driven at 50% crank speed. Scavenge stages should have wider gears than the pressure stage, at 36mm and 28mm respectively.

Oil Viscosity

Both 5W40 and 5W30 can be recommended for this engine. The 40-weight oil will likely have strong oil film strength at high RPM, but the 30-weight oil can lower internal temperature and increase power output.

Final Words

Needless to say, we should use oil squirters under the pistons, high quality bolts and studs for the rotating assembly, and a bedplate setup for the crankshaft. In the next post, I will discuss the top-end.