techXXX

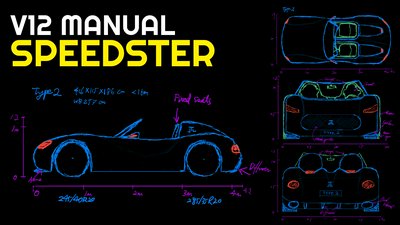

Designing the Fuelling, Cooling, and Accessories for a 3L NA 11.5k-rpm V12—If I Had a Car Company 07

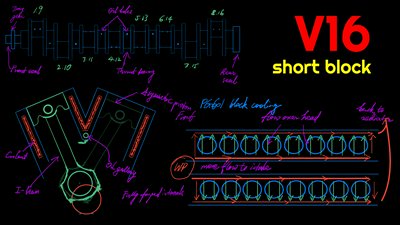

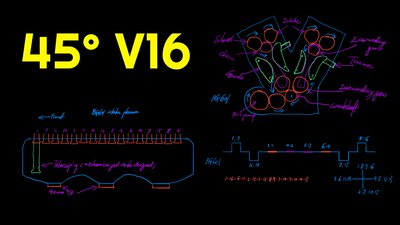

Previously, I have delved into the short-block, cylinder head, and intake / exhaust systems of the 3L NA V12 PC301. Today, let us round out the deep dive with fuelling, cooling, and accessories.

Previously, I have delved into the engine block, rotating assembly, cylinder head, and intake / exhaust systems of the 3L NA V12 engine that I would build. Today, let us round out the deep dive with fuelling, cooling, and accessories, specifically:

- Fuel delivery: Port injection

- Injectors: Need high-performance injectors

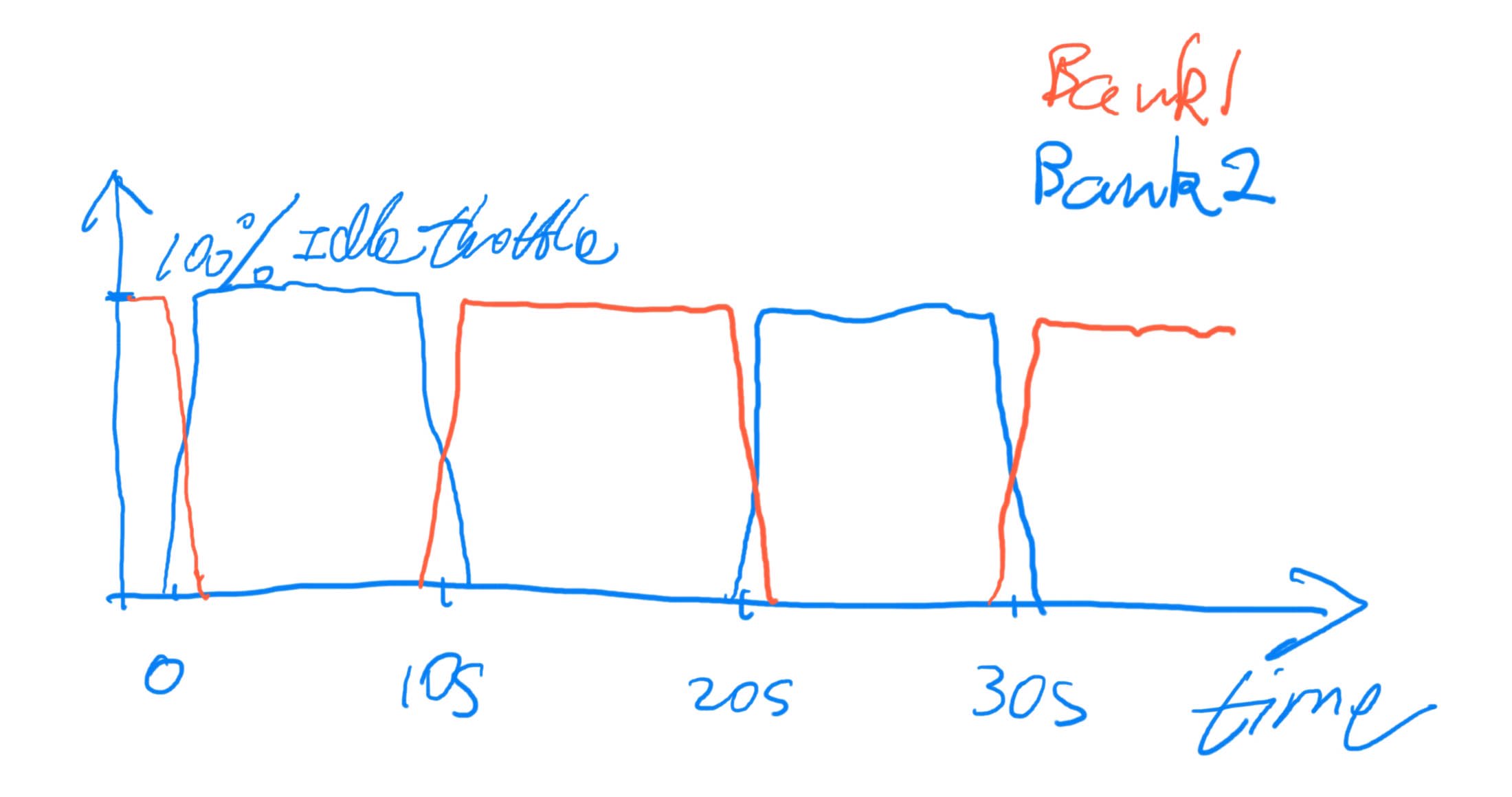

- Bank switching: Alternate bank shutoff with 10s intervals

- Firing order: 1–7–5–11–3–9–6–12–2–8–4–10

- Belt-driven accessories: Water pump, alternator, AC compressor (optional)

- Radiators: Main rad + condenser M, Oil cooler L, Cold air intake R

Port Injection and Idle Bank Shutoff

Port injection is the correct choice for a high-revving, naturally-aspirated V12. Direct injection would have just 2 to 3ms of window to work over 10k RPM, and with a small bore, it would affect air flow, squish, and mixture homogeneity negatively. It would certainly make less power and likely produce higher levels of pollutants. While DI helps with knock, our engine is naturally knock-resistant.

Still, with ITBs we can save some fuel and further reduce emissions using idle shutoffs. In this strategy, we will run only half the engine at idle and switch from one bank to the other every 10s. When shut off, a bank’s throttles will be closed, and no fuel is injected. While it does not help reduce pumping loss, unlike full cylinder deactivation, this does save fuel and reduce idle emissions. Obviously, this strategy should be defeatable by the owner at any time.

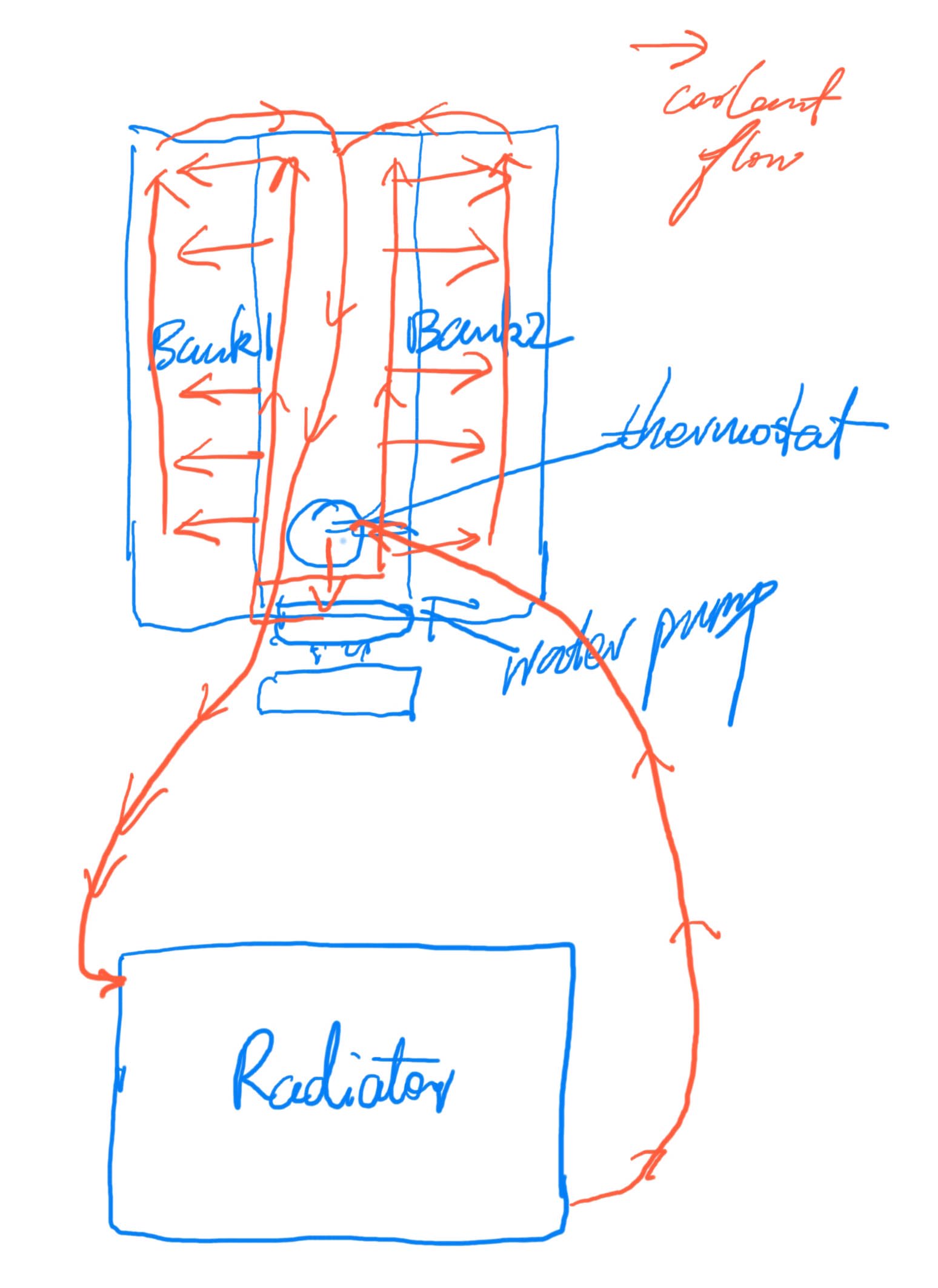

Water and Oil Cooling

Thanks to its Nikasil-coated aluminum block, which is a great medium to conduct heat compared to iron or steel liners, and to natural aspiration, our engine has an easy time with cooling even with a closed decked water jacket. Nevertheless, we should take cooling seriously and use a large radiator, engine-driven water pump, and mechanical 90°C thermostat. No plastic should be found anywhere in the cooling system.

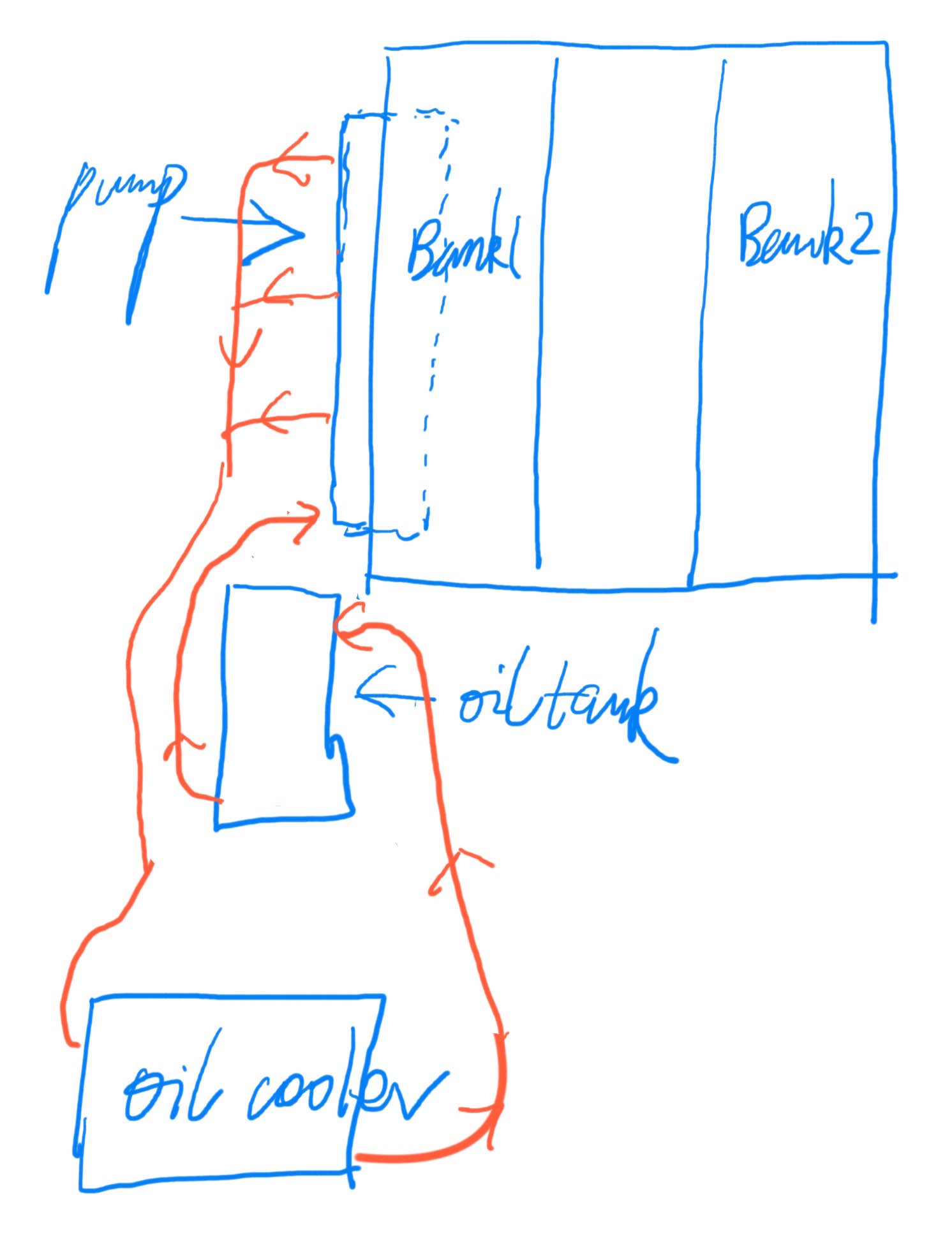

Additionally, we will install a standalone oil-to-air cooler between the scavenging stages and the external oil tank. It is placed here because this stabilizes oil temperature and helps with de-aeration in the tank. A thermostat is not needed.

Belt Drive

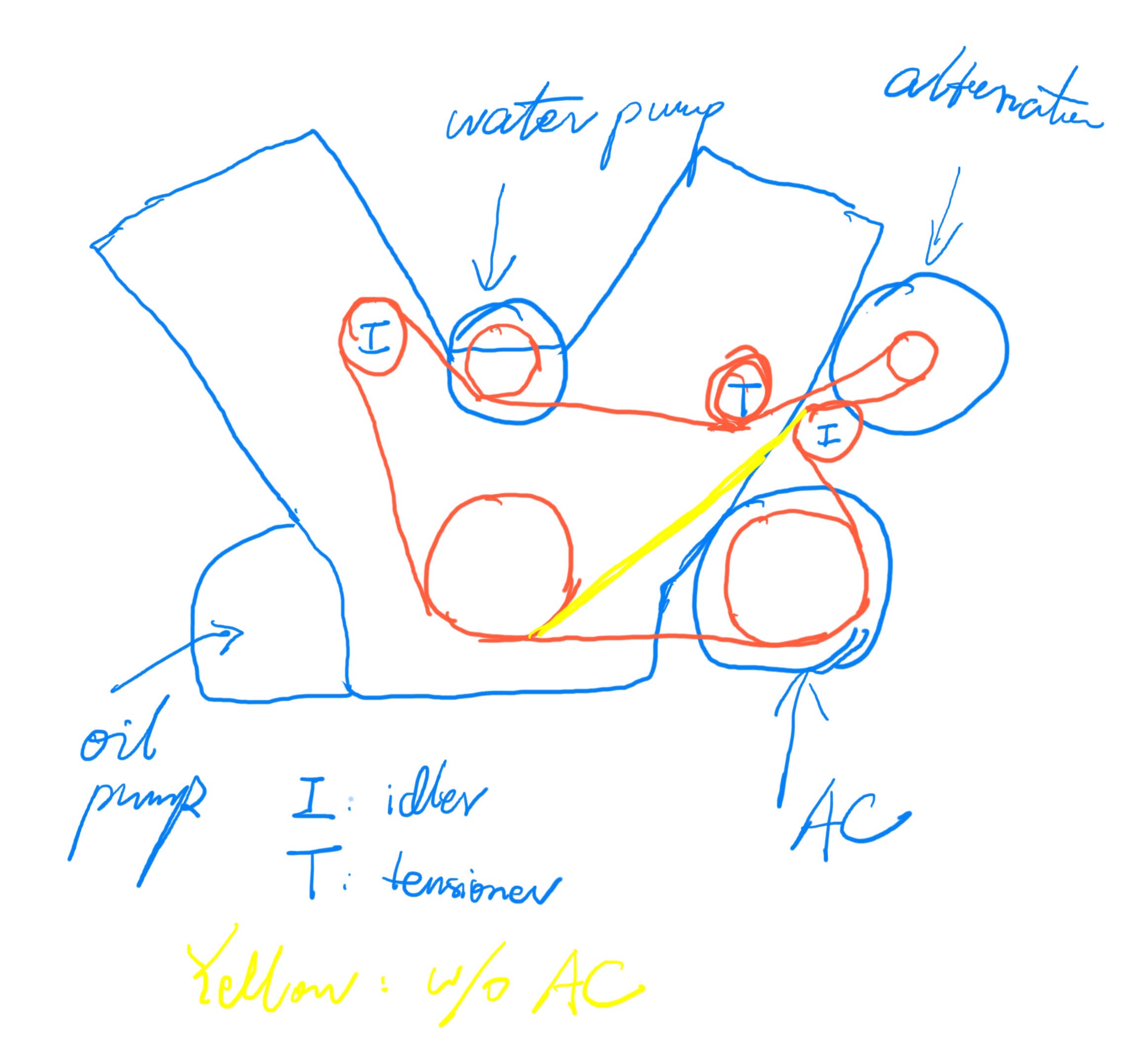

The water pump and the alternator are belt driven. For weight savings, an AC compressor should be an optional equipment. The water pump is placed at the tip of the valley. Both the optional AC compressor and the alternator are placed on the outer edge of Bank 2, because the oil pump and external oil tank occupy the other side. The alternator should be above the AC compressor.

Note that it is important for the serpentine belt to wrap over 180° around the alternator, because the load is high and variable. On the other hand, the wrap on the water pump should be small, because the load is low while the service life of the bearing and seal is important.

We have two idlers and one tensioner whether the AC compressor is optioned or not. Indeed, the owners can retrofit or delete the AC easily.

Next Up

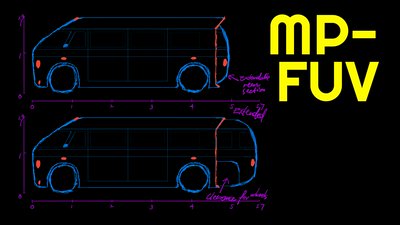

In the next post, I will discuss the transmission and drivetrain layout of my mid-size GT, Type 1.